Construction and maintenance operation method of cast-in-place roadbed slab type ballastless track

A ballastless track and ballast bed slab technology, which is applied in tracks, track laying, track maintenance, etc., can solve the problems of long condensation time and overall replacement of the bed slab, and achieve the effects of low failure rate, simple process and light equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation and beneficial effects of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

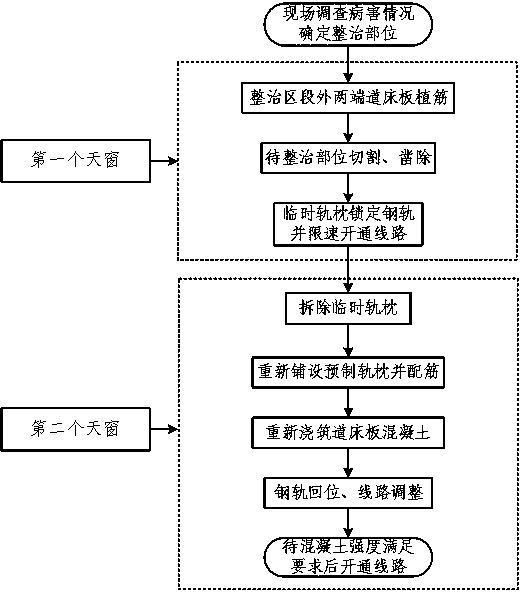

[0036] The embodiment of the present invention provides a method for construction and maintenance of cast-in-place bed slab ballastless track, the method specifically includes the following contents and procedures (see attached figure 1 ).

[0037] (1) On-site investigation of cast-in-place ballastless track disease conditions, to determine the need for remediation.

[0038] (2) The track bed slabs at both ends of the track bed slab section to be rehabilitated shall be drilled and reinforced.

[0039] (3) Thoroughly cut and chisel off the track bed slabs and sleepers at the parts to be treated.

[0040] (4) After laying temporary sleepers and locking rails, open the line at a speed limit.

[0041] (5) Remove temporary sleepers.

[0042] (6) Re-lay the prefabricated sleepers and configure the steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com