Organic sewage treatment equipment and treatment method thereof

A technology for treating equipment and organic sewage, which is applied in the field of water treatment, can solve problems such as small investment, and achieve the effect of large profits, considerable profits, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

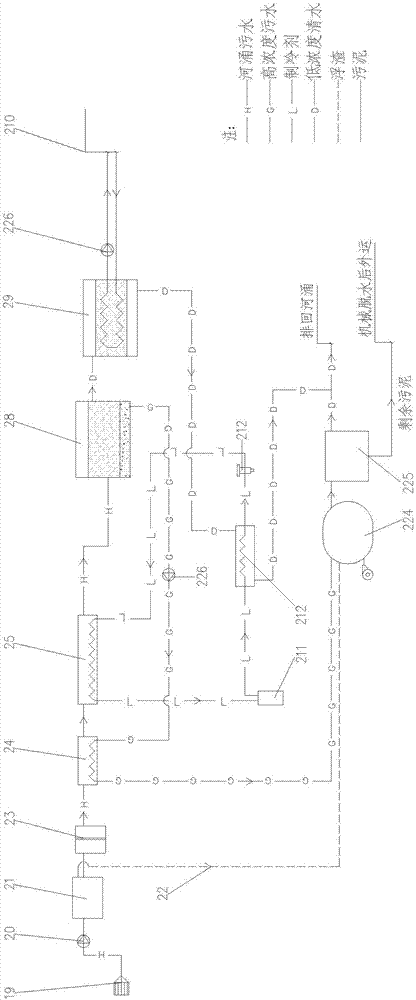

[0095] Example 1: Such as image 3 As shown in the schematic diagram of the non-anaerobic flow of the black and smelly water body, when the treatment station is too close to the residential building, the biogas storage tank 222 has potential safety hazards. The low-temperature and high-concentration sewage in the lower part of the refrigerator 28 exchanges heat with the raw water of the river gushing sewage through the first heat exchanger 24, and becomes normal-temperature high-concentration sewage, which is sent to the aerobic reactor 224 for treatment, and then sent to the sedimentation tank 225. The upper part of the sedimentation tank 225 discharges 0.2 volume of clean water (COD is about 34.5 mg / L, and the removal rate is 85%). The discharged clean water and the normal temperature clean water heated by the condenser 212 are mixed into 1 volume (COD about 11 mg / L) clean water and discharged from the treatment station.

[0096] The COD of the treated effluent is about 11mg / L,...

Embodiment 2

[0097] Example 2: Such as Figure 4 As shown in the schematic diagram of the process of treating black and odorous water in summer conditions, the high-concentration sewage at the lower part of the refrigerator 28 at 0℃ exchanges heat with the raw sewage of the river through the first heat exchanger 24, and becomes 0.2 volume of 23℃ high-concentration sewage (COD About 230mg / L), and then sent to the mud water mixer 218. At the same time, 0.1 volume of 27°C river sludge (COD is about 4000mg / L) is fed into the mud-water mixer 218. The river sludge is first passed through the grit tank 216 and then filtered through the second fine grid 217 to remove larger insoluble Solid matter. The high-concentration sewage and river sludge are mixed in the mud-water mixer 218 to form a 0.3-volume 25°C mud-water mixture (COD is about 1500 mg / L). The mud-water mixture is sent to the auxiliary condenser 219, heated to 36°C by the 40°C refrigerant at the outlet of the heat pump system compressor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com