Self-positioning dynamic elasticity modulus test apparatus

A dynamic elastic modulus and testing device technology, which is applied in measuring devices, measuring resonance frequency, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of reducing the accuracy of test results, difficult to ensure the accuracy of scribing, troublesome operation, etc., to achieve The structure is simple, the operation is convenient, and the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

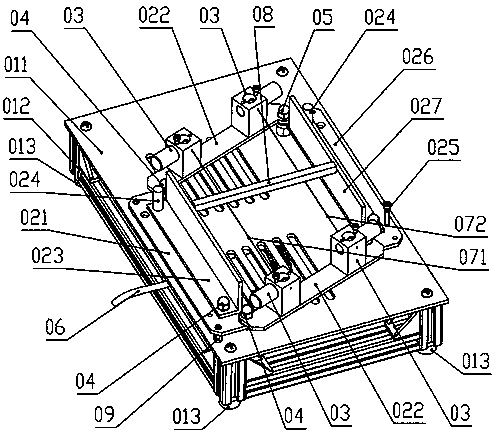

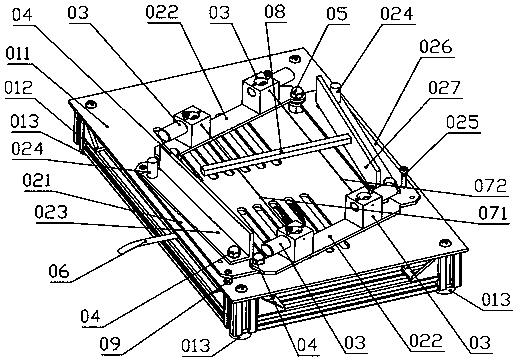

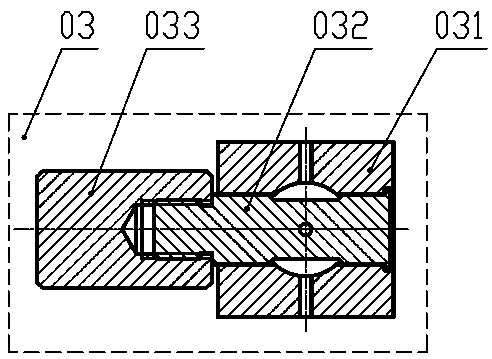

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, a self-positioning dynamic modulus of elasticity testing device of the present invention is composed of a base assembly 01, a parallelogram positioning mechanism 02, a wire support assembly 03, a rotating shaft assembly 04, a support shaft assembly 05, a microphone assembly 06, and a restraining wire a071, constrained pull wire b072, constant section test piece 08 and strut nut 09; base assembly 01 includes panel 011, strut frame 012 and foot support 013, parallelogram positioning mechanism 02 includes fixed plate 021, connecting plate 022, limit stopper Plate a023, positioning pin 024, locking screw 025, adjusting plate 026 and limit baffle b027, the cable support assembly 03 includes a positioning seat 031, a winding shaft 032 and a hand wheel 033, and the rotating shaft assembly 04 includes cap nuts 041, Anti-friction copper pad 042 and rotating pin shaft 043, the support shaft assembly 05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com