Ozone gas heating mechanism, substrate processing device, and substrate processing method

A substrate processing device and gas heating technology, applied in electrical components, semiconductor/solid-state device manufacturing, discharge tubes, etc., can solve problems such as the influence of oxide film characteristics, and achieve the effect of reducing the deviation of substrate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the structure which is substantially the same, and repeated description is abbreviate|omitted.

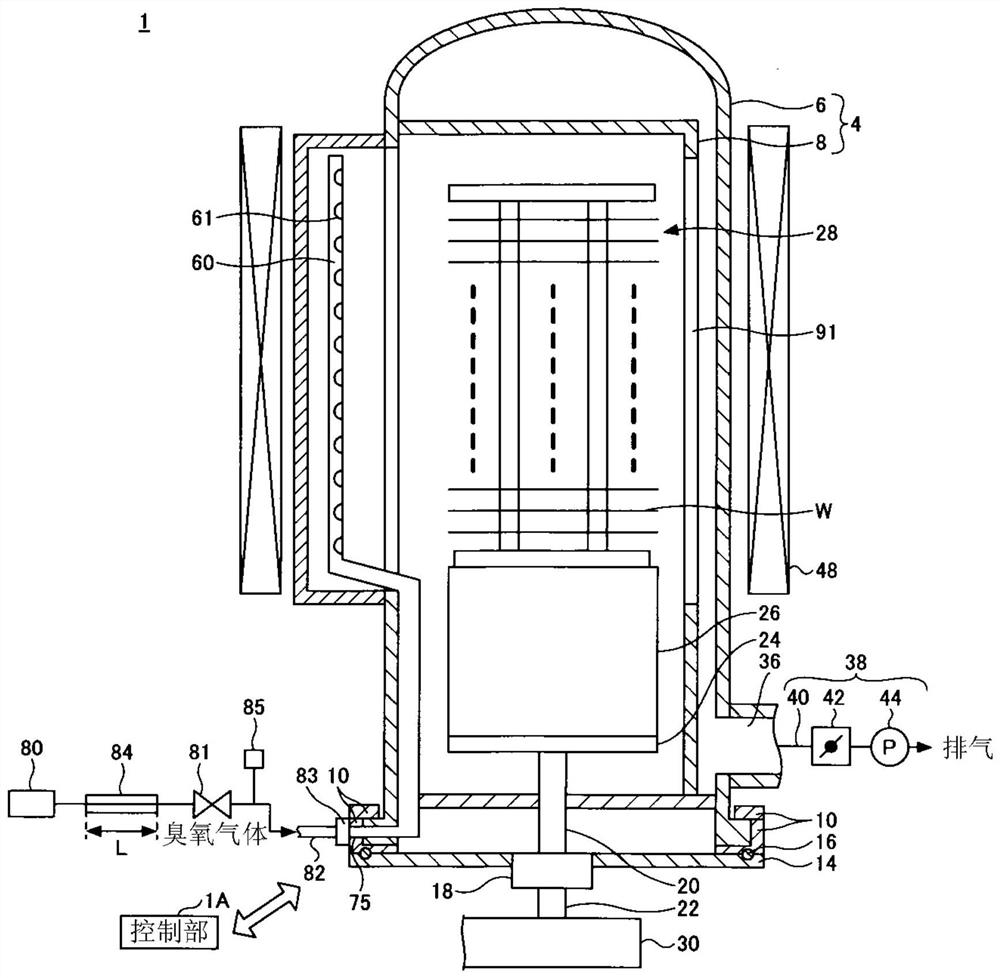

[0020] A substrate processing apparatus according to an embodiment of the present invention will be described. figure 1 It is a schematic cross-sectional view of the substrate processing apparatus according to the embodiment of the present invention.

[0021] Such as figure 1 As shown, the substrate processing apparatus 1 has a substantially cylindrical processing container 4 whose longitudinal direction is in the vertical direction. The processing container 4 has a double pipe structure including an outer cylinder 6 having a top and an inner cylinder 8 arranged concentrically with the outer cylinder 6 inside the outer cylinder 6 and having a top. The lower end of the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap