Vacuum pump

A vacuum pump and stator technology, applied in pumps, axial flow pumps, pump components, etc., can solve problems such as inability to rotate and achieve the effect of reducing temperature deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

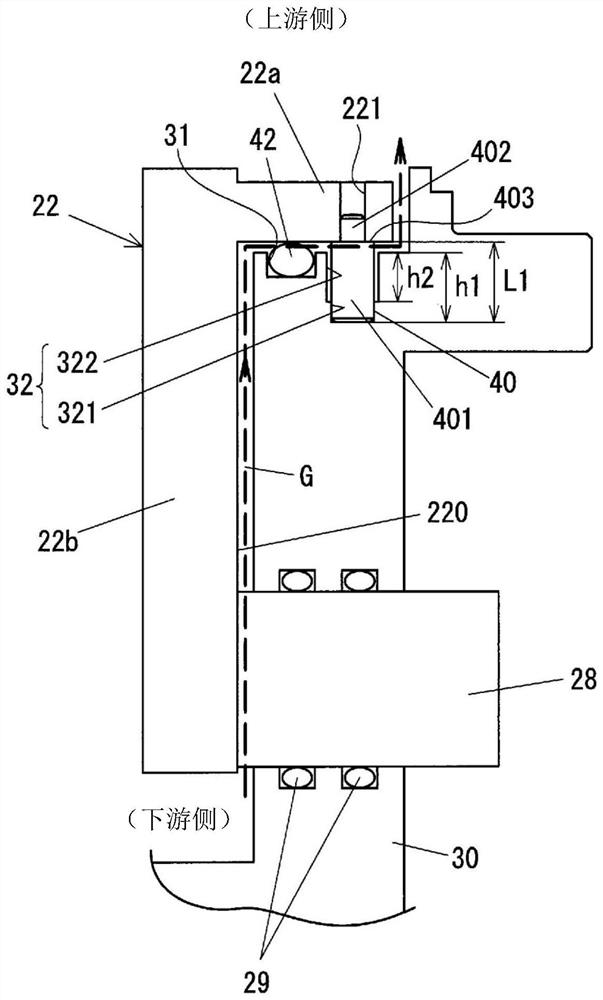

[0082] Figure 7 It is a figure which shows the modification 1 of this embodiment. In Modification 1, the O-ring 42 is arranged between the outer peripheral surface of the stator 22 and the inner peripheral surface of the base 30 like a shaft seal. Even when the O-ring 42 is arranged in this manner, the reverse flow of the gas as indicated by the dotted arrow G can be prevented. exist Figure 7 In the above, the O-ring groove 31 is provided in the base 30 , but it may also be provided in the stator 22 . Likewise, in figure 2 In the structure shown, the O-ring groove 31 may be provided on the side of the flange portion 22a.

Deformed example 2

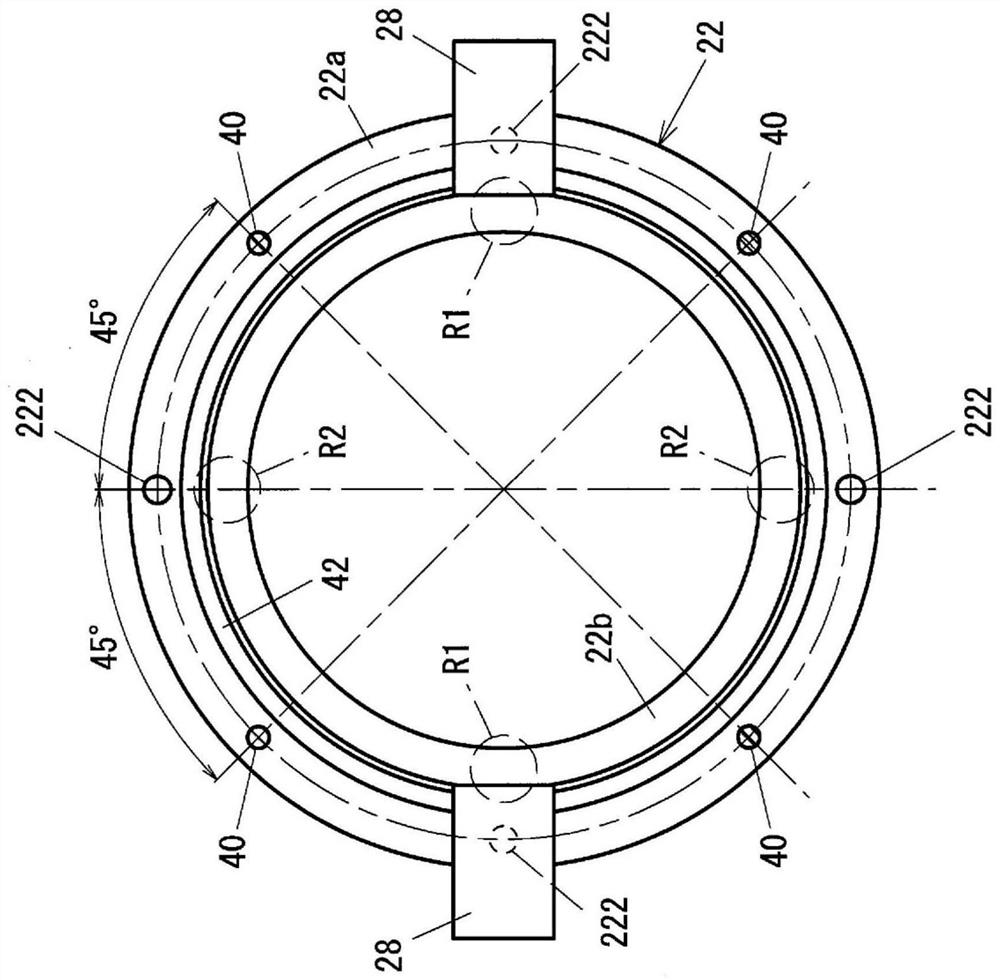

[0084] Figure 8 It is a figure which shows the modification 2 of this embodiment. In Modification 2, the parallel pins 44 are used instead of the stepped pins 40 . Similar to the stepped pin 40 , the parallel pin 44 is formed of a material having a lower thermal conductivity than the stator 22 and the base 30 . The structure of the pin hole 32 into which the parallel pin 44 is inserted is the same as figure 2 The pin holes 32 shown are of the same construction. That is, the pin hole 32 has a small-diameter hole portion 321 that engages with the parallel pin 44 and a large-diameter hole portion 322 that forms a gap with the parallel pin 44 . In the case of this structure, the flange portion 22 a of the stator 22 is supported by the plurality of parallel pins 44 , thereby positioning the stator 22 in the pump axis direction.

[0085] In addition, in Modification 2, the positioning of the stator 22 with respect to the radial and circumferential phases is, for example, as fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap