Centrifugal air preheater

An air preheater and centrifugal technology, applied in lighting and heating equipment, indirect carbon dioxide emission reduction, combustion methods, etc., can solve problems such as flue gas outlet temperature deviation, ammonium bisulfate scaling, and corrosion of metal heating surfaces. To achieve the effect of reducing the deviation of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

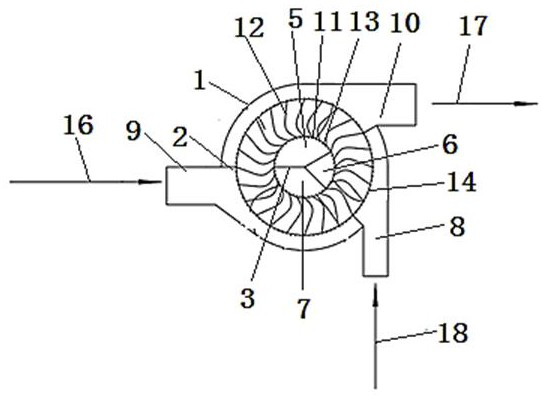

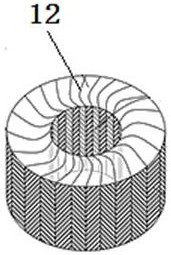

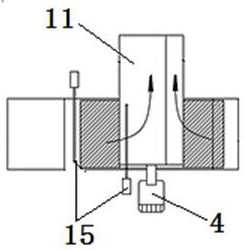

[0028] Such as figure 1 As shown, a centrifugal air preheater includes a casing 1, a centrifugal heat exchange assembly rotatably arranged in the casing, a soot blower 15 and a soot leakage pipe. The casing 1 is a cylindrical casing, including a first The circular plate, the second circular plate and the arc plate, the center of the second circular plate has a first through hole, the outer edge of the first through hole is folded outwards and extended to form a smoke duct 11, the center of the centrifugal heat exchange assembly The channel communicates with the cavity of the smoke duct 11 to form a smoke duct. The smoke duct 11 is provided with a first partition 3 , and the first partition 3 extends along the axial direction of the smoke duct 11 throughout the entire smoke duct. The partition 3 is sealed and fixed to the inner wall of the smoke duct 11. The end face of the first partition 3 is Y-shaped. The first partition 3 is composed of three straight plates. The first part...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap