Film heating/molding device of blister packaging machine

A blister packaging machine and thermoforming technology, used in packaging, transportation and packaging, multiple packages, etc., can solve the problems of easy deformation of pockets and poor work efficiency, improve thermal conductivity, reduce deviation, and prevent leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

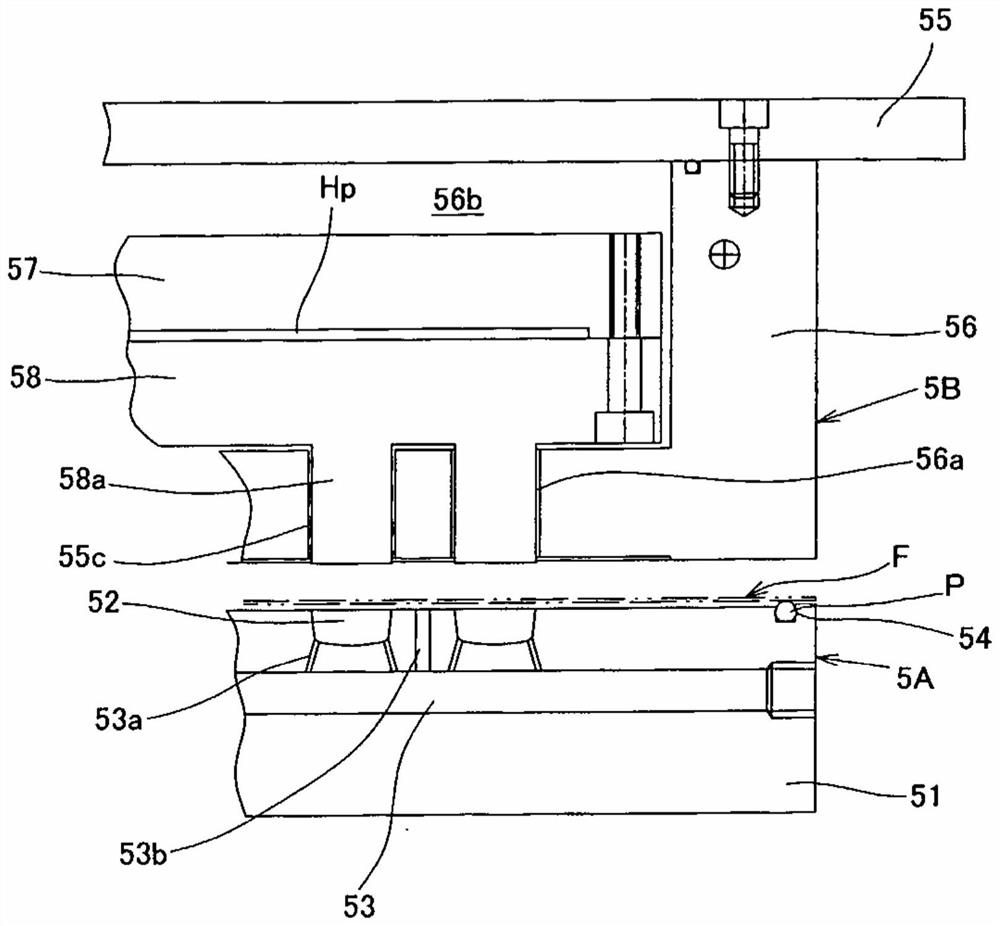

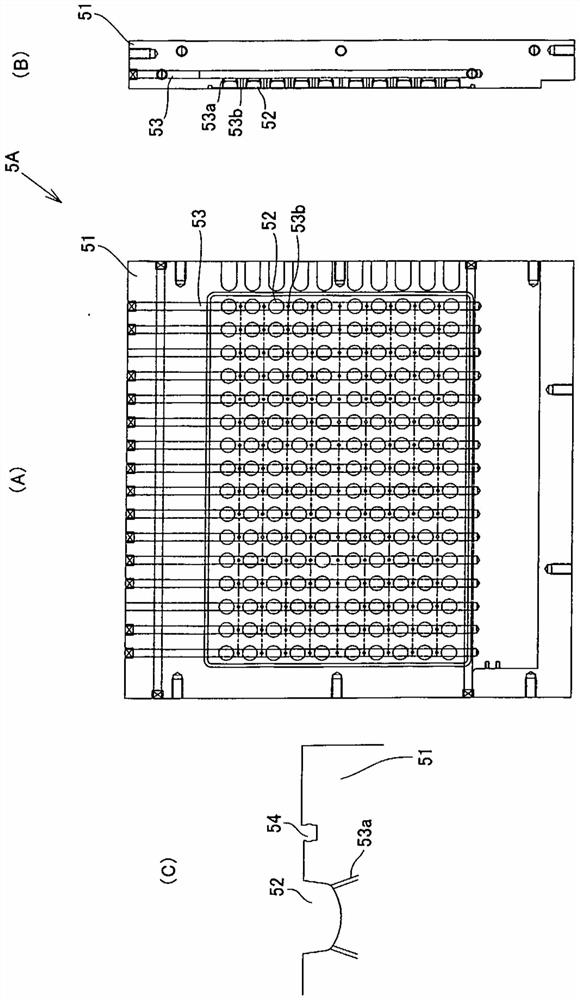

[0028] Hereinafter, embodiment of the thermoforming apparatus of the film in the blister packaging machine of this invention is demonstrated based on drawing.

[0029] Figure 1 ~ Figure 3 An example of the film thermoforming device of the blister packaging machine of the present invention is shown.

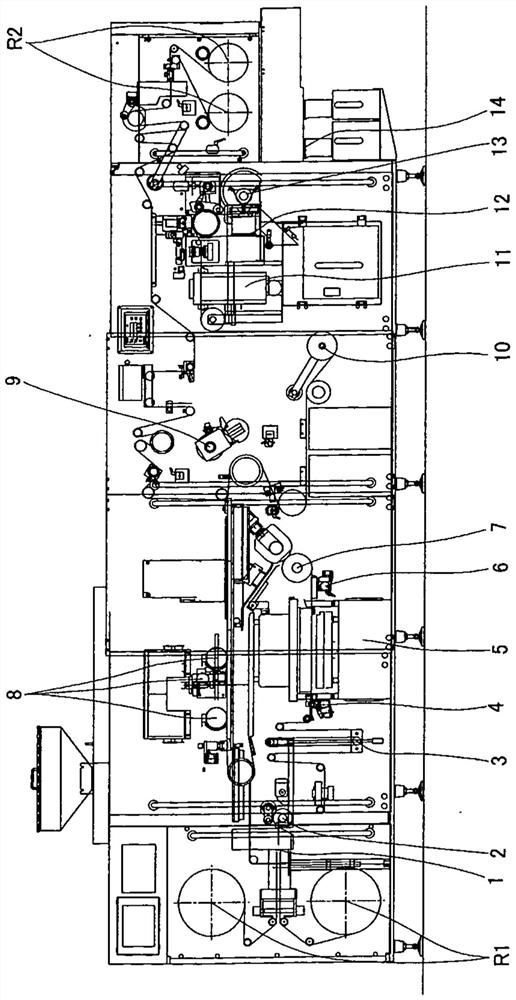

[0030] The blister packaging machine as figure 1 As shown, the film F that is sequentially released from the film roll R1 formed by winding a film F such as a polypropylene film passes through the film connecting device 1 and is released by the discharge roller 2. After the tension is adjusted by the constant tension roller 3, it is released by the guide roller 4. It is intermittently supplied to the next thermoforming device 5. Here, after forming the required pockets, the tablets are supplied to each pocket by the tablet supplying device 8 via the guide roller 6 and the forming film conveying roller 7. After tableting, the aluminum film roll R2 formed by winding the sheet-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com