Installation process of square hopper door of dredger

An installation process, a technology for dredgers, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of many processes, increased labor force, and troublesome operation, so as to reduce operating procedures, high work efficiency, and lighten work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

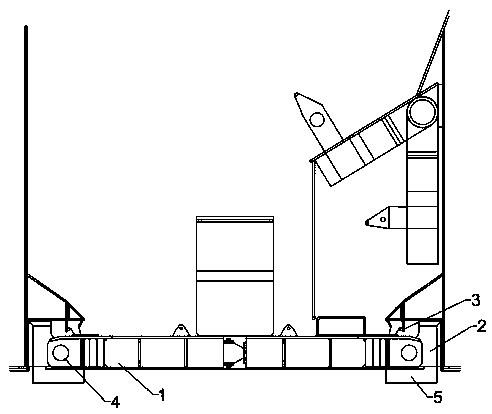

Image

Examples

Embodiment Construction

[0019] Taking the square mud door of a 7000m3 trailing suction dredger as an example for further explanation.

[0020] The embodiment of the present invention provides an installation process of a square mud door of a dredger, and the technical scheme is as follows:

[0021] The first step is to place the mud door body horizontally on the temporary tire frame, connect the mud door ear plate 2 to the mud door body 1 through the pin shaft, use tooling to make the ear plate 2 and the mud door body 1 level, and the mud door pin shaft The tolerance of the lug hole 4 of the mud door should meet the requirements of IHC (before installing the mud door, ensure that the subsections within the range of the mud door are level, the flatness of the outer bottom plate should not be greater than 4mm, and the height difference between the mud door and the bottom plate of the ship should be not more than 2mm).

[0022] In the second step, the left and right mud doors 1 are arranged completely,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com