Novel full-automatic paper stack elevator

A fully automatic, elevator technology, applied in the direction of lifting devices, can solve the problem of high labor intensity, and achieve the effect of low manufacturing cost, labor cost saving, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

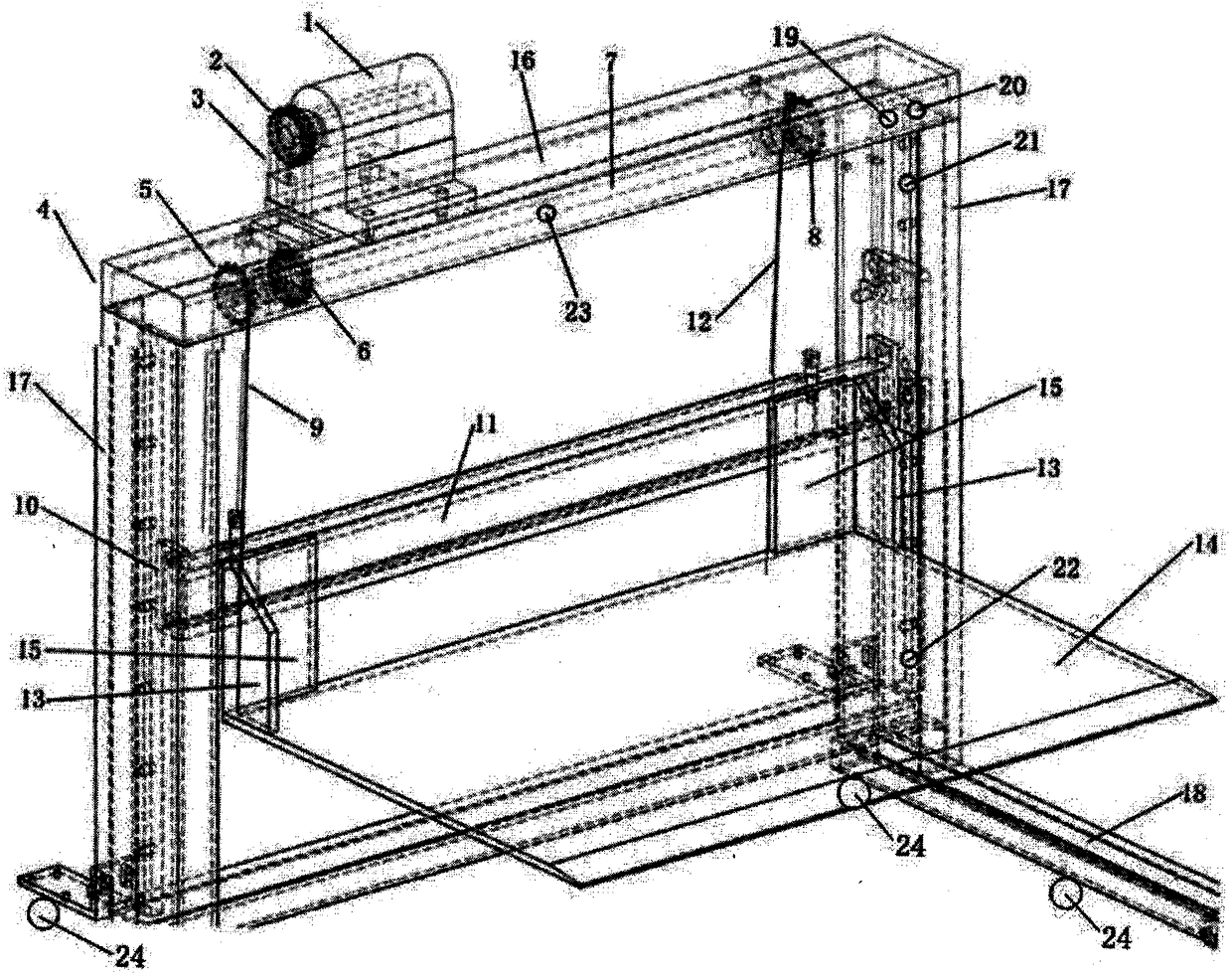

[0015] Such as figure 1 As shown, a novel full-automatic paper pile lifter of the present invention includes a support 4, and the support 4 is composed of a crossbeam 16 provided on the top and two columns 17 vertically arranged to support the crossbeam 16. The lower part is also provided with stabilizing legs 18 .

[0016] A motor 1 is installed on the top of the beam 16, and a driving wheel 2 is installed on the rotating shaft of the motor 1;

[0017] A rotatable rotating rod 7 is installed below the crossbeam 16, and the two ends of the rotating rod 7 are respectively fixed on two columns 17 through ball bearings, and the rotating rod 7 is sequentially sleeved with left and right shafts from left to right. Driven wheel 5, driving wheel 6, right driven wheel 8, described driving wheel 6 is connected with driving wheel 2 by main chain 3;

[0018] A slide plate 11 is installed below the rotating rod 7, and the two ends of the slide plate 11 are fixed in the chute 10 inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com