Preparation method of pure cotton white fabric with long-lasting whiteness

A fabric and white technology, which is applied in the field of preparation of lasting whiteness of pure cotton white fabrics, can solve the problems of insufficient washing fastness, etc., and achieve the effect of convenient operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

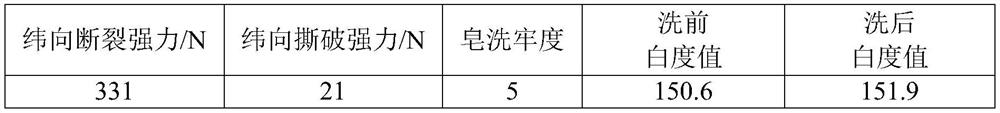

Embodiment 1

[0025] Using 60 counts of pure cotton in the warp and weft direction, the density is 180*100, the finished product width is 58 inches, the weave is 1 / 1 plain weave, and the finishing method is ordinary finishing. The specific implementation steps are as follows:

[0026] (1) Singeing: Confirm the process according to the organizational specifications, select the position of the burner, burner 2, the flame intensity is 12mbar, and the vehicle speed is 90 m / min.

[0027] (2) Desizing: process parameters: steamer temperature 98°C, cloth stacking time 13 minutes, washing temperature 90°C, vehicle speed 80 m / min, desizing with enzymatic desizing.

[0028] (3) Mercerizing: According to the tissue specifications, determine the alkali concentration of 21 degrees Baume, the spray temperature of 65°C, the washing tank of 70°C, and adjust the pH value to 7.

[0029] (4) Whitening: add stabilizer 4g / L, hydrogen peroxide 15g / L, caustic soda 4g / L, whitening agent 5g / L according to tissue sp...

Embodiment 2

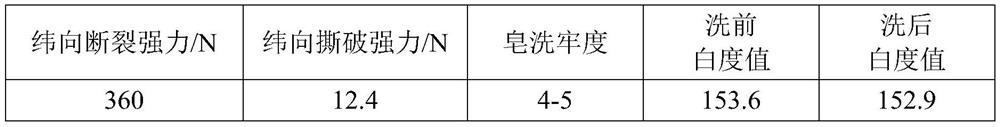

[0035] Using 70 counts of pure cotton in the warp and weft direction, the density is 200*100, the finished product width is 59 inches, the weave is 1 / 1 plain weave, and the finishing method is ordinary non-ironing. The specific implementation steps are as follows:

[0036] (1) Singeing: Confirm the process according to the organizational specifications, select the position of the burner, burner 2, the flame intensity is 12mbar, and the vehicle speed is 90 m / min.

[0037] (2) Desizing: process parameters: steamer temperature 98°C, cloth stacking time 15 minutes, washing temperature 95°C, vehicle speed 80 m / min, desizing by enzymatic desizing.

[0038] (3) Mercerizing: According to the tissue specifications, determine the alkali concentration of 21 degrees Baume, the spray temperature of 60°C, the washing tank of 75°C, and adjust the pH value to 7.5.

[0039] (4) Whitening: add stabilizer 5g / L, hydrogen peroxide 20g / L, caustic soda 6g / L, whitening agent 6g / L according to the wea...

Embodiment 3

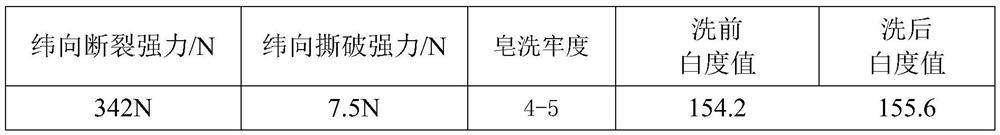

[0045] Using 40 counts of pure cotton in the warp and weft direction, the density is 130*85, the finished product width is 57 inches, the weave is 1 / 1 plain weave, and the finishing method is tide crosslinking. The specific implementation steps are as follows:

[0046] (1) Singeing: Confirm the process according to the organizational specification, select the position of the burner, burner 2, the flame intensity 14mbar and the vehicle speed 90 m / min.

[0047] (2) Desizing: process parameters: steamer temperature 98°C, cloth stacking time 15 minutes, washing temperature 95°C, vehicle speed 80 m / min, desizing by enzymatic desizing.

[0048] (3) Mercerizing: According to the tissue specifications, determine the alkali concentration of 23 degrees Baume, the spray temperature of 60°C, the washing tank of 75°C, and adjust the pH value to 7.5.

[0049] (4) Whitening: add 6g / L of stabilizer, 25g / L of hydrogen peroxide, 8g / L of caustic soda, and 7g / L of whitening agent according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com