Operation and maintenance operation detection method and device and electronic equipment

A technology for operation and maintenance operations and detection methods, applied in the field of system services, can solve problems such as misjudgment and inaccurate judgment results, and achieve the effect of accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

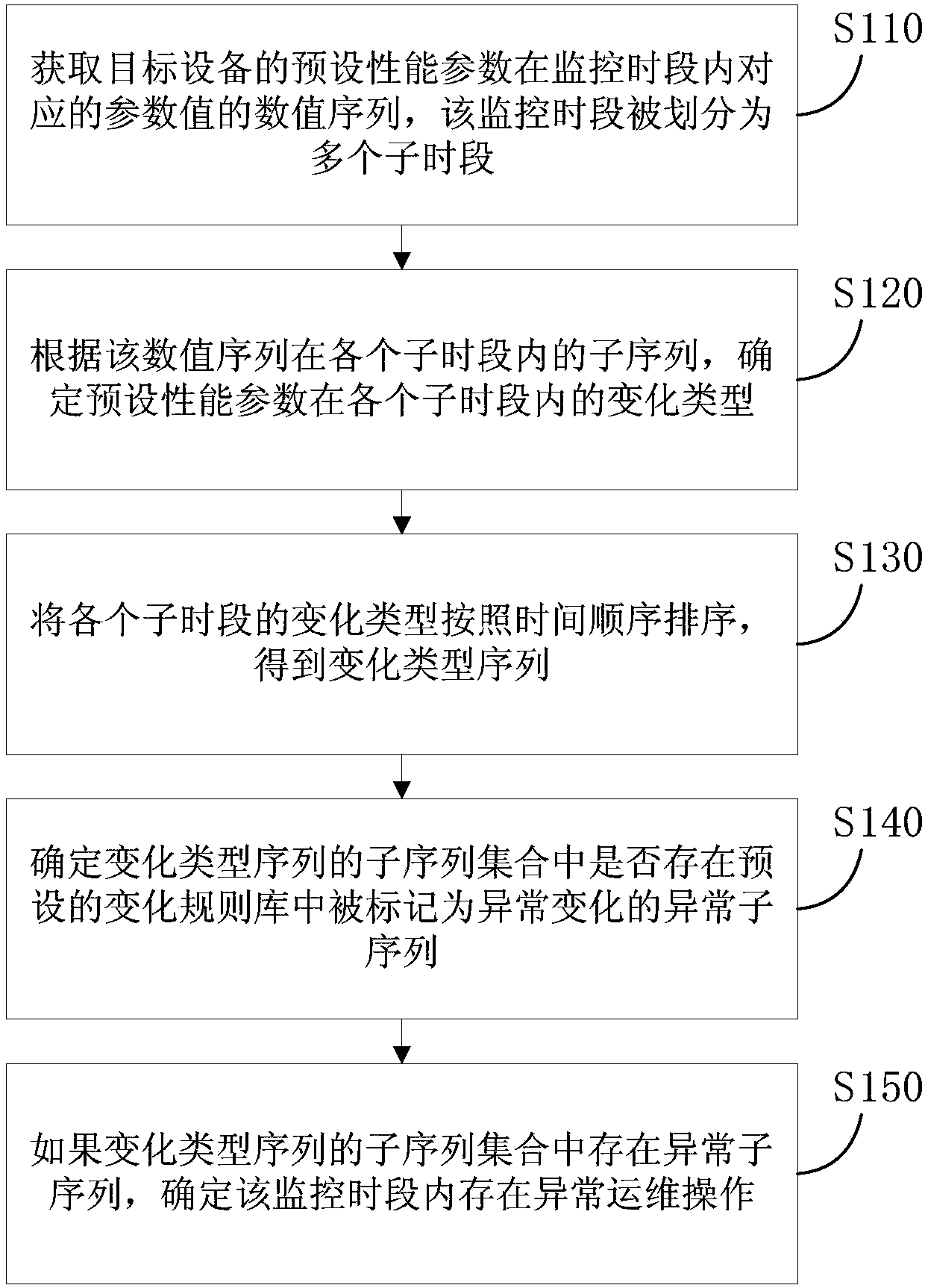

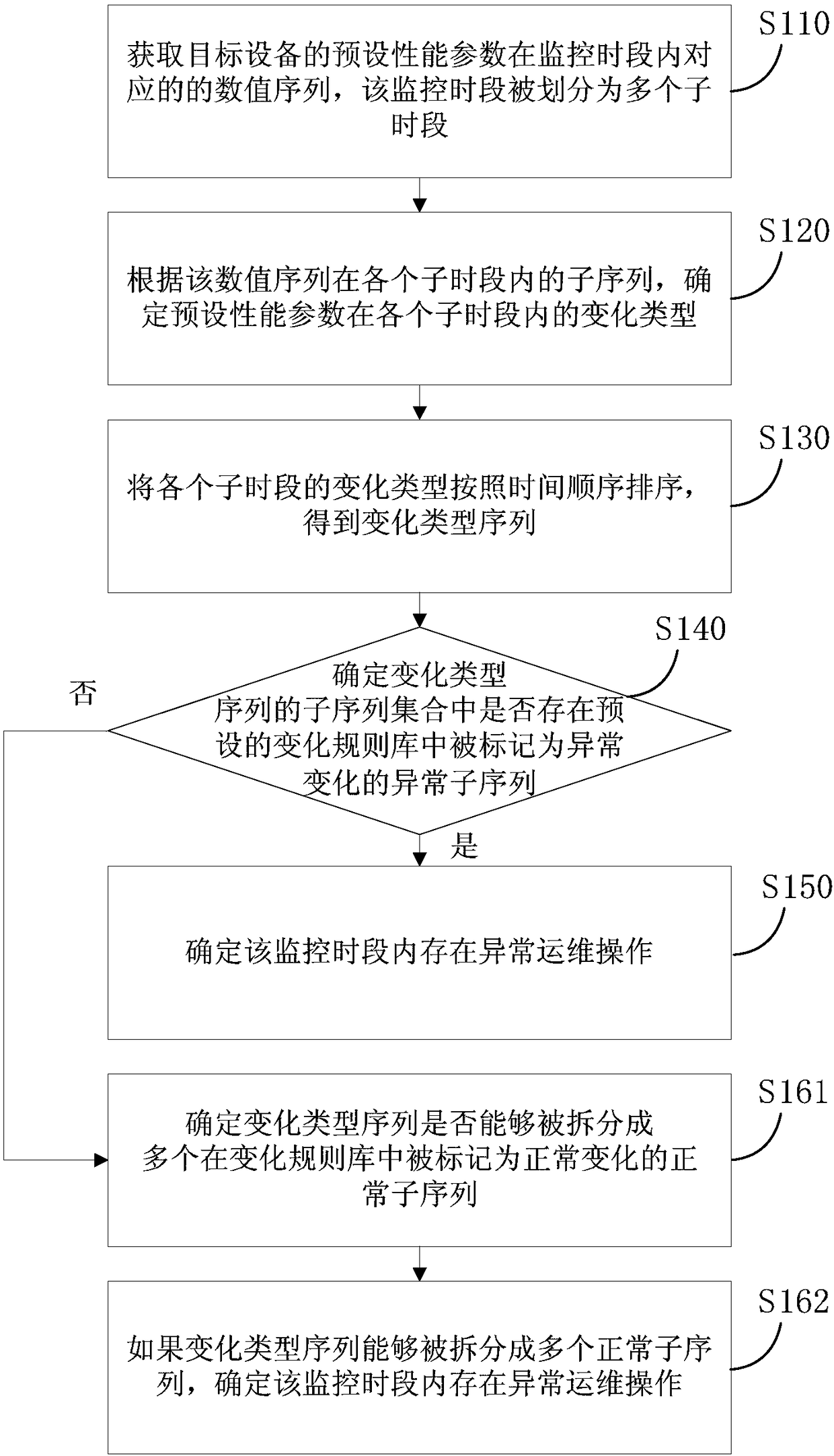

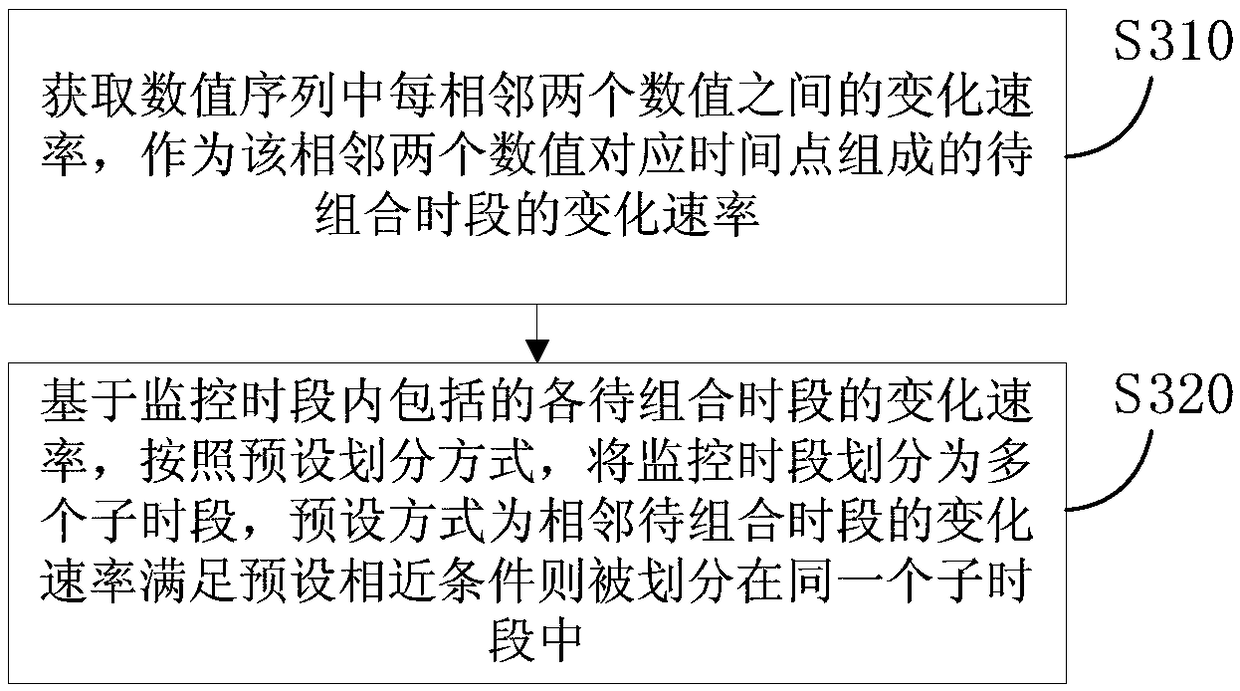

[0059] see figure 1 , figure 1 Shown is a schematic flowchart of the operation and maintenance operation detection method provided by the embodiment of the present invention, which may include the following steps:

[0060] S110. Acquire a numerical sequence corresponding to a preset performance parameter of the target device within a monitoring period, where the monitoring period is divided into multiple sub-periods.

[0061] Wherein, the preset performance parameter may be a CPU load rate, or a server visit volume, or other parameters that can reflect the performance index of the target device. It is understandable that changes in the performance parameters of the target device can reflect whether the target device is in an abnormal state. For example, when the CPU load rate rises rapidly and remains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com