A side chain type alkyl sulfonated polybenzimidazole ion exchange membrane and its preparation method

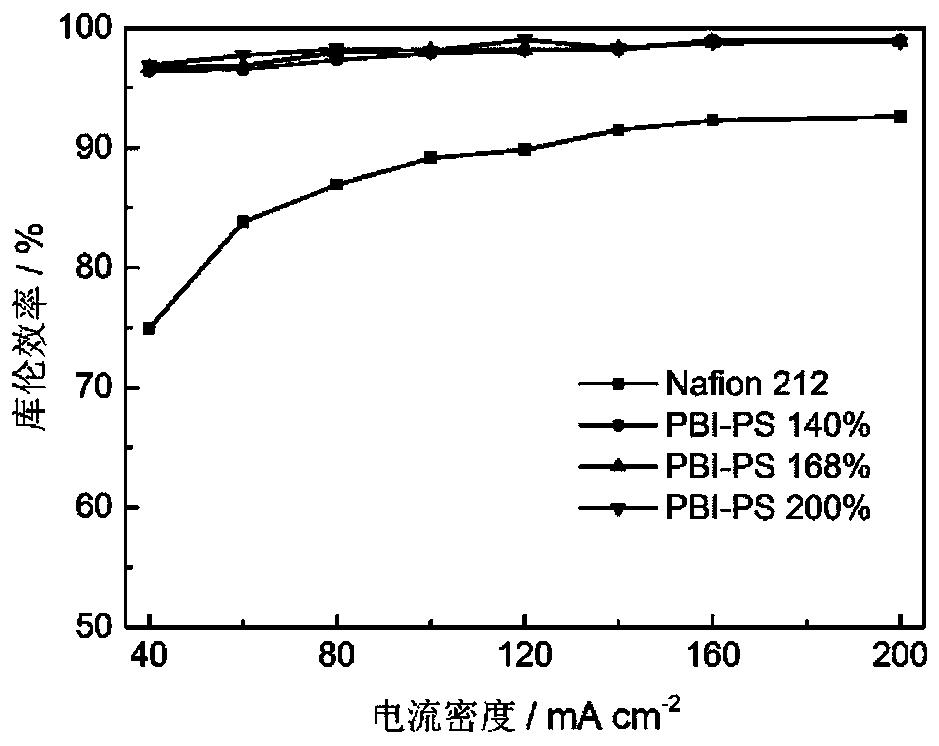

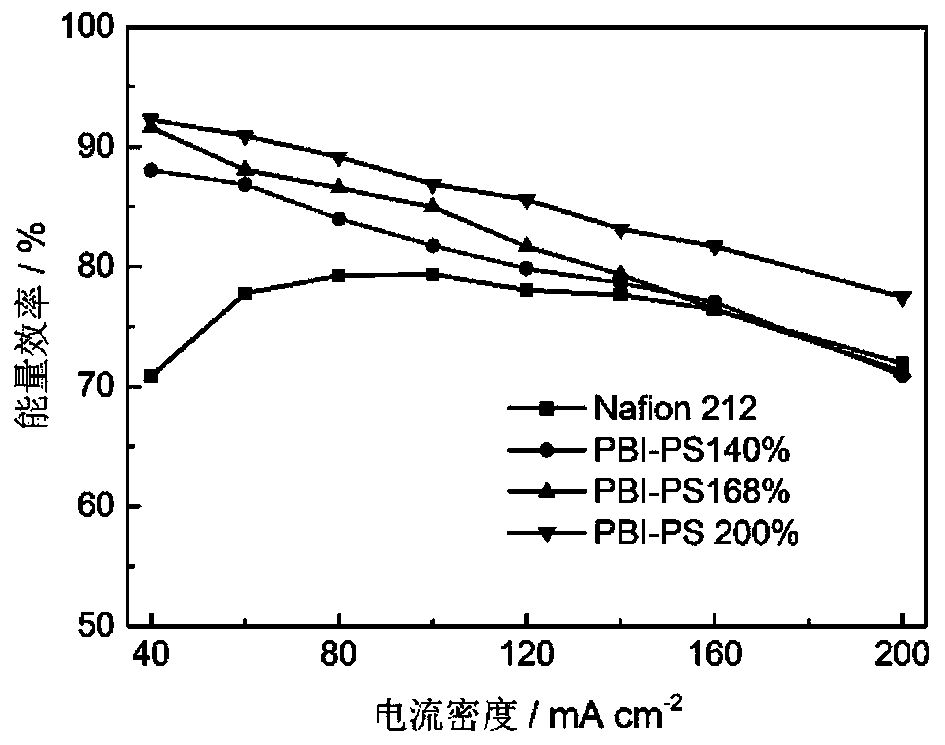

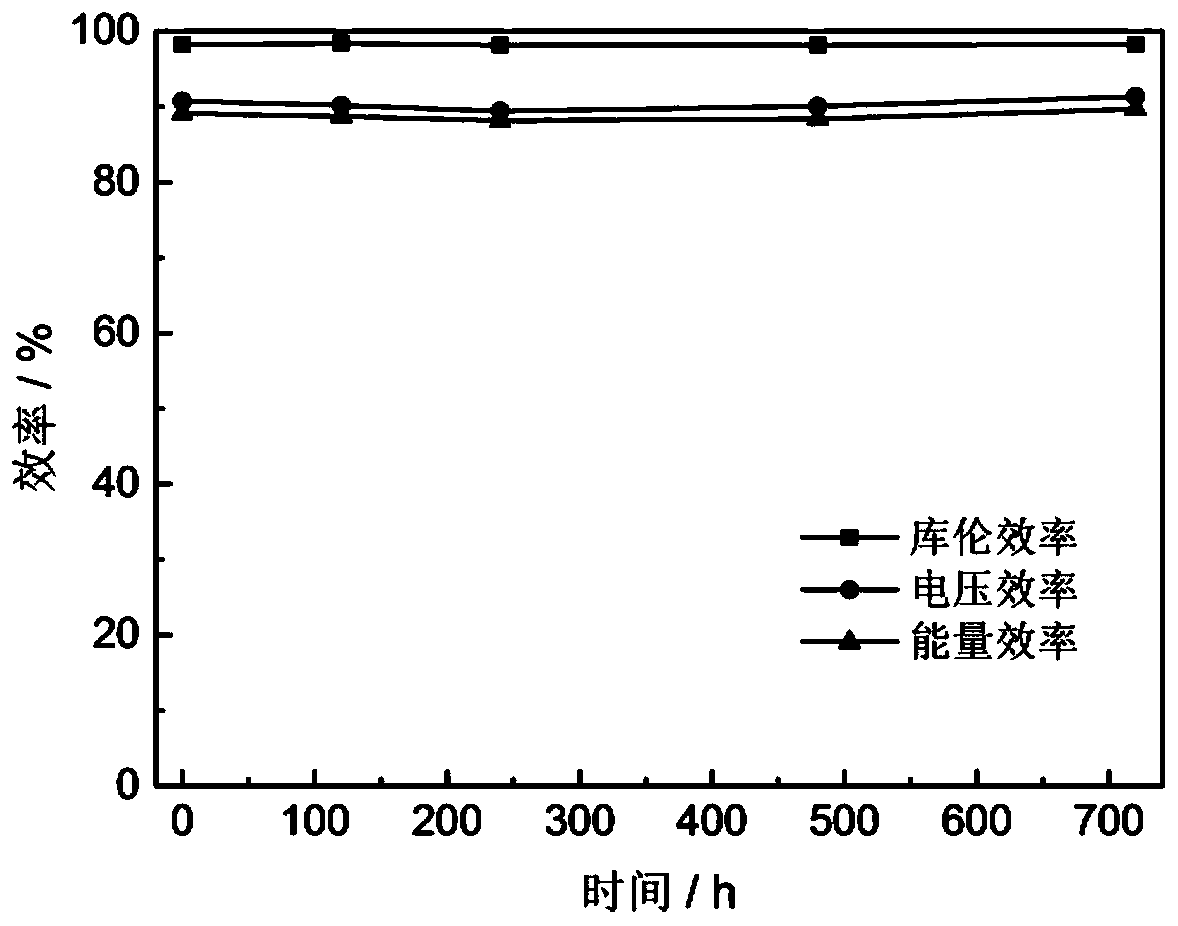

A polybenzimidazole, ion exchange membrane technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of restricting full-scale commercial application, high price, serious vanadium ion permeability, etc., and achieve low vanadium. Effects of ion permeability, good chemical stability, and high proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dehydrogenation of polybenzimidazole: 1 g of polybenzimidazole was dissolved in dimethyl sulfoxide to prepare a solution with a w / v concentration of 2.5%. Under the protection of inert gas, add 0.14g of sodium hydride and react at 40°C for 3h;

[0027] Lactone ring opening: add 0.53g of 1,3-propane sultone to the dehydrogenated reaction system, and react at 40°C for 8h. After the reaction, the reaction product was precipitated in acetone, washed repeatedly, filtered and dried in a vacuum oven at 30° C. for 12 hours to obtain a brown-yellow powder.

[0028] Preparation of the alkylsulfonated polybenzimidazole membrane: the above reaction product was dissolved in dimethyl sulfoxide to prepare a casting solution with a w / v concentration of 4%, and the membrane was degassed by centrifugation. Using the solution casting method, spread the casting solution on a glass plate, place it in an oven at 80°C, and dry it. After the solvent was completely evaporated, the membrane wa...

Embodiment 2

[0031] Dehydrogenation of polybenzimidazole: 1 g of polybenzimidazole was dissolved in dimethylformamide to prepare a solution with a w / v concentration of 2.5%. Under the protection of inert gas, add 0.168g of sodium hydride and react at 30°C for 4h;

[0032] Lactone ring opening: add 0.64g of 1,3-propane sultone to the dehydrogenated reaction system, and react at 40°C for 8h. After the reaction, the reaction product was precipitated in acetone, washed repeatedly, filtered and dried in a vacuum oven at 30° C. for 12 hours to obtain a brown-yellow powder.

[0033] Preparation of the alkylsulfonated polybenzimidazole membrane: the above reaction product was dissolved in dimethyl sulfoxide to prepare a casting solution with a w / v concentration of 4%, and the membrane was degassed by centrifugation. Using the solution casting method, spread the casting solution on a glass plate, place it in an oven at 80°C, and dry it. After the solvent was completely evaporated, the membrane wa...

Embodiment 3

[0036] Dehydrogenation of polybenzimidazole: Dissolve 1g of polybenzimidazole in 50mL of dimethylformamide, add 0.2g of sodium hydride under the protection of inert gas, and react at 30°C for 4h;

[0037] Lactone ring opening: add 0.76g of 1,3-propane sultone to the dehydrogenated reaction system, and react at 50°C for 8h. After the reaction, the reaction product was precipitated in acetone, washed repeatedly, filtered and dried in a vacuum oven at 30° C. for 12 hours to obtain a brown-yellow powder.

[0038] Preparation of the alkylsulfonated polybenzimidazole membrane: the above reaction product was dissolved in dimethyl sulfoxide to prepare a casting solution with a w / v concentration of 4%, and the membrane was degassed by centrifugation. Using the solution casting method, spread the casting solution on a glass plate, place it in an oven at 80°C, and dry it. After the solvent was completely evaporated, the membrane was removed, placed in 1mol / L sulfuric acid solution for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com