Cable pipeline structure and sealing method used in spacecraft ventilation duct

A technology for ventilation ducts and spacecraft, applied in electrical components and other directions, can solve problems such as poor cable sealing, and achieve the effect of enhancing the sealing effect, avoiding wear or scratches, and avoiding air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] According to one embodiment of the present invention, the method for sealing the cable pipeline structure of the present invention includes:

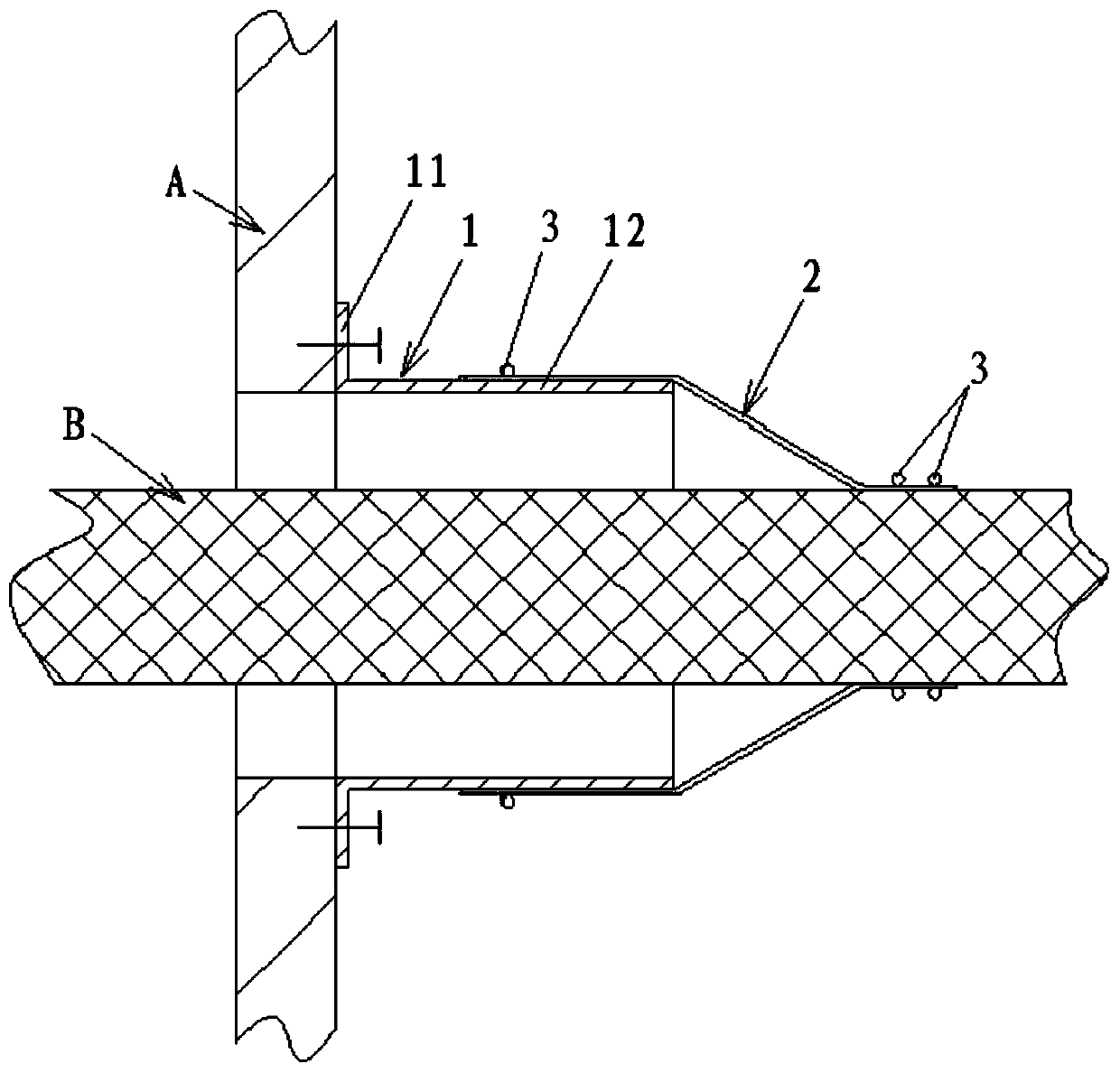

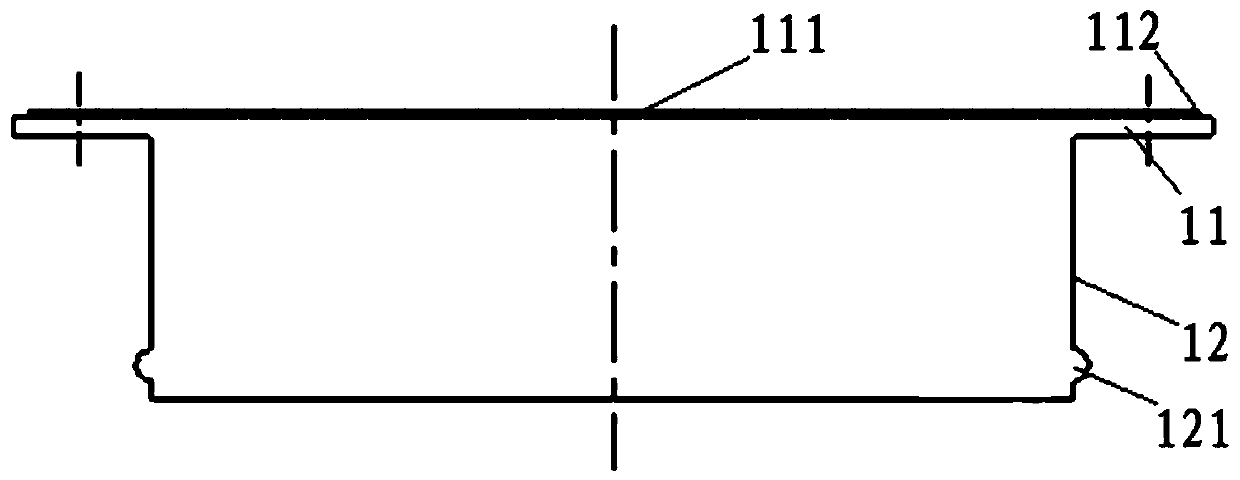

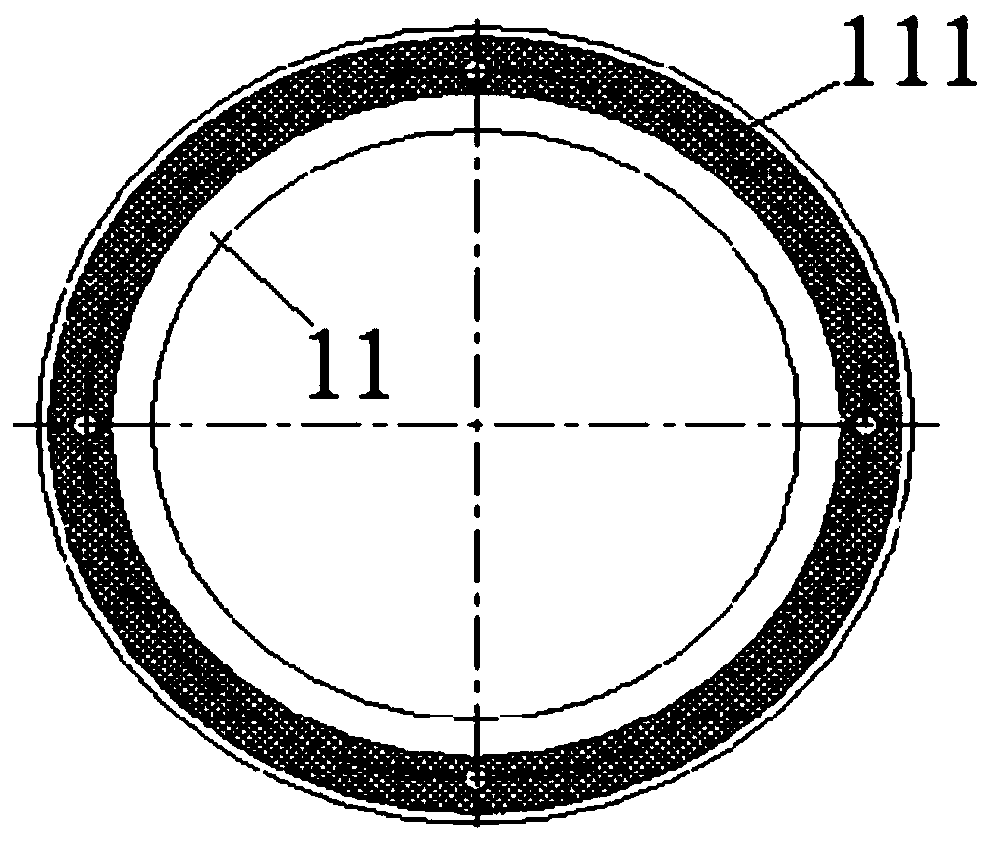

[0040] S1. Connect the base 11 with the cable hole on the side wall A of the ventilation duct of the spacecraft, set the connecting pipe 2 on the body 12, and fasten the connecting pipe 2 with nylon cable ties 3 . In this embodiment, the base 11 is connected to the side wall A by screws, and the annular seal 111 is compressed by the base 11 .

[0041] S2. Tighten the connecting pipe 2 and the cables passing through the connecting pipe 2 with nylon cable ties 3 . In this embodiment, there are at least two nylon cable ties 3 at the fastening position between the connecting pipe 2 and the cable. By fastening the connecting pipe 2 and the cable B, the gap between the connecting pipe 2 and the cable B becomes smaller, thereby further ensuring the tightness of the connecting pipe 2 and the cable B, and enhancing the cable pipeline str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com