Cooling device after paint spraying of motor rotor coil

A technology for rotor coils and cooling equipment, applied in the manufacture of motor generators, electric components, electrical components, etc., can solve problems such as shortening the process flow and affecting the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

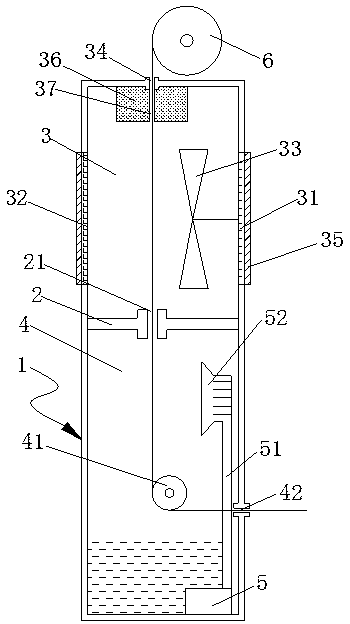

[0016] Such as figure 1 Shown: a cooling device for motor rotor coils after painting, including a cuboid cooling cylinder 1, a partition 2 is arranged in the middle of the cooling cylinder 1, and the partition 2 divides the cooling cylinder 1 into a drying chamber 3 and a water shower Chamber 4, a water pump 5 is installed at the bottom of the water shower chamber 4, a steering roller 41 is installed in the water shower chamber 4, a first line hole 42 is arranged on the side wall of the water shower chamber 4, and a first wire hole 42 is arranged on the side wall of the water shower chamber 4. A line hole 42 is horizontally opposite to the turning roller 41, and a second line hole 21 is arranged on the partition plate 2, and the second line hole 21 is vertically opposite to the turning roller 41. The two left and right sides of the drying chamber 3 are The side walls are respectively provided with an air inlet groove 31 and an air outlet groove 32, and a fan 33 is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com