An assembly device for a space-assembled antenna assembly unit

A technology for assembling units and assembling devices, which is applied to antenna supports/mounting devices, antennas suitable for movable objects, etc., can solve problems such as poor adaptability, and achieve the effects of compact structure, light weight, and prevention of operational errors

Active Publication Date: 2014-08-27

XIAN INSTITUE OF SPACE RADIO TECH

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, foreign countries have developed special quick connection and separation devices for their respective space-assembled antenna assembly units, including plate buckle structures and passive electric locking mechanisms. However, these assembly devices are highly specialized and are not suitable for other types of assembly. The structural adaptability of the unit is poor. In view of the structural characteristics of the top hinge of the large-scale assembled space antenna assembly unit, an assembly device that can adapt to the top hinge of different installation positions for quick connection and assembly is needed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

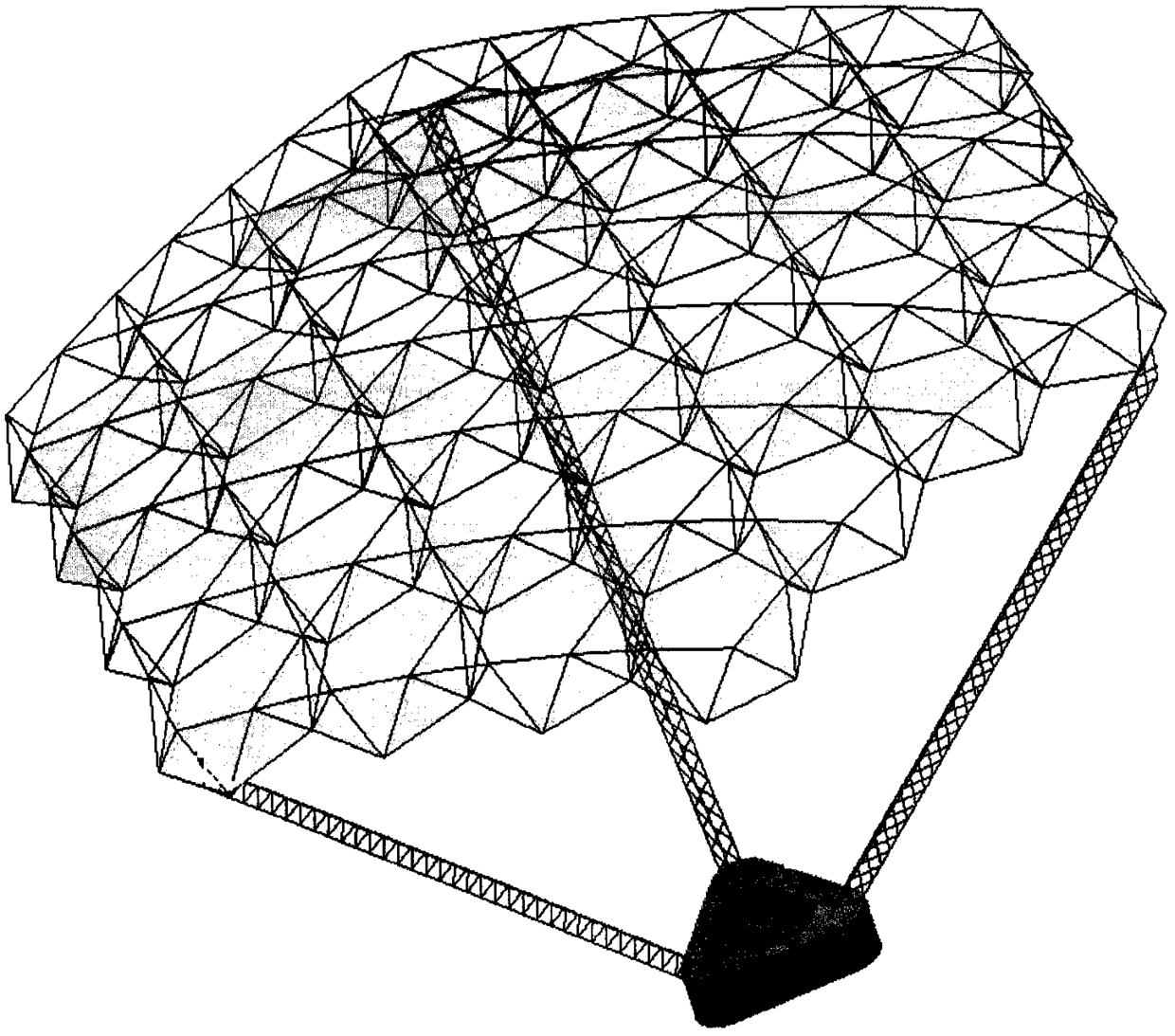

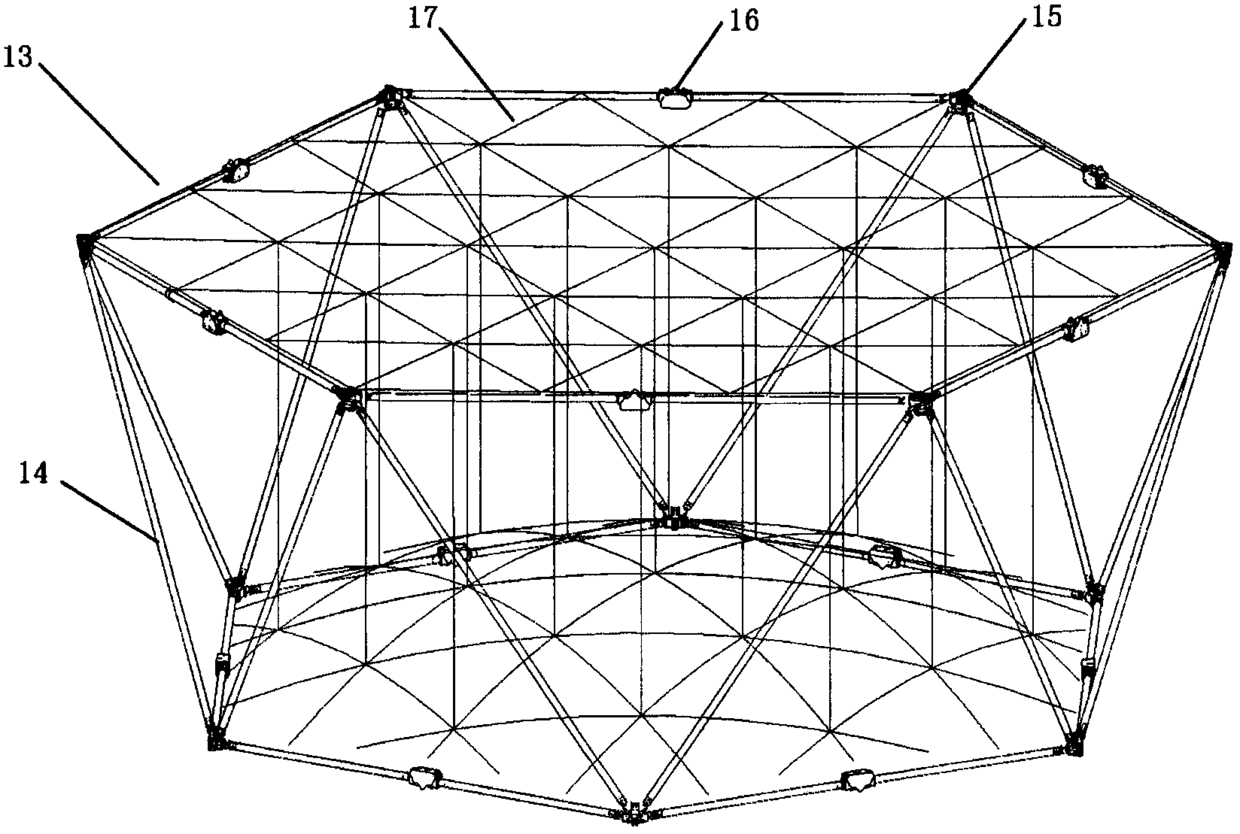

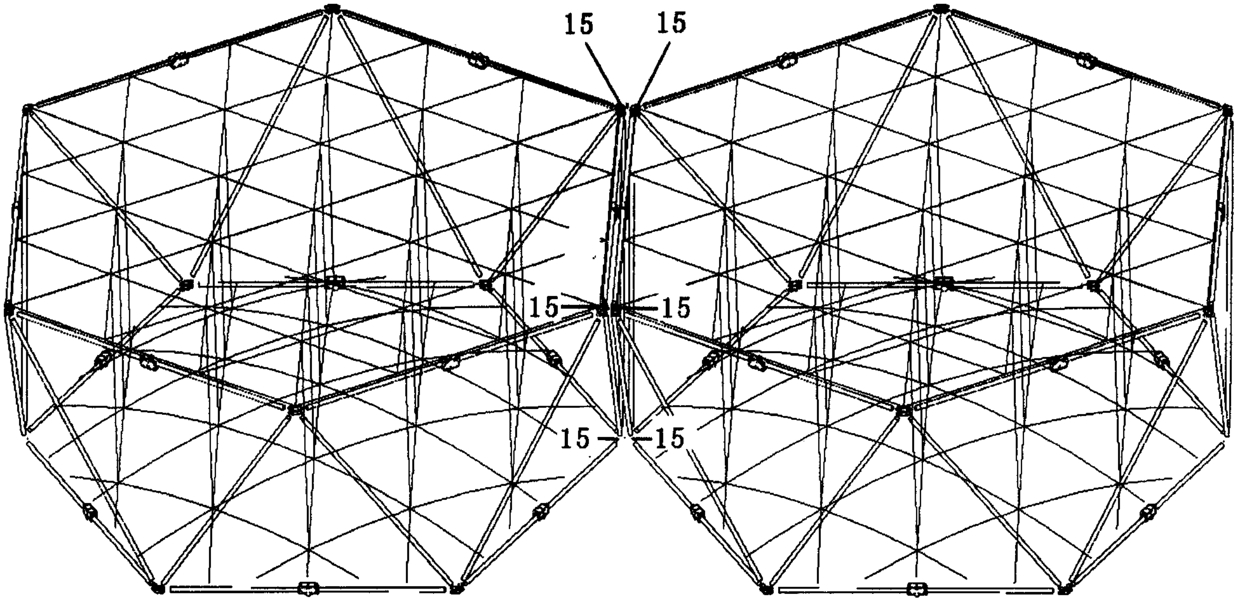

The invention relates to an assembly device of a space-assembled antenna assembly unit, which mainly includes a docking ball head, a docking cylinder, a rotating cylinder, a docking ball socket, a pre-tightening compression spring, a pre-tightening torsion spring, a ball stud, and a ball stud Pre-tightening compression spring, compression spring limit block, butt cylinder end cover, pre-tightening force adjustment screw, deep groove ball bearing and other components. The butt ball head is limited by the ball stud pin and the butt ball socket in the docking cylinder cavity, the ball stud pin is fixed on the docking cylinder by the ball stud pin pre-tightened compression spring, and the compression spring limit block, and the butt socket is adjusted by the preload The screw and the pre-tightening torsion spring are connected to the end cover of the butt joint. By adjusting the pre-tightening force to adjust the length of the screw, the pre-tightening force of the butt ball socket and the butt ball head can be adjusted. There is a pre-tightening torsion spring between the butt joint and the rotating cylinder. , the torsion spring makes the unlocking hole on the rotating cylinder staggered with the ball stud, and the ball stud is limited by the rotating cylinder. At this time, the butt joint ball is limited by the ball stud, and the butt joint cannot be inserted or pulled out.

Description

technical field The invention relates to an assembly device of a space assembly type antenna assembly unit, belonging to the technical field of space assembly type antennas. Background technique At present, foreign countries have developed special quick connection and separation devices for their respective space-assembled antenna assembly units, including plate buckle structures and passive electric locking mechanisms. However, these assembly devices are highly specialized and are not suitable for other types of assembly. The structural adaptability of the unit is poor. In view of the structural characteristics of the top hinge of the large-scale assembled space antenna assembly unit, an assembly device that can adapt to the top hinge of different installation positions for quick connection and assembly is needed. The assembly device requires strong structural adaptability, high reliability and requirements for various large-scale assembled space antenna assembly units. C...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01Q1/12H01Q1/28

Inventor 黄志荣王波王耀霆郑士昆马小飞徐晓龙

Owner XIAN INSTITUE OF SPACE RADIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com