Kinetic friction force-based kernel removing device for deep processing of apples

A dynamic friction, deep-processing technology, applied in fruit pitting devices, applications, food science, etc., can solve the problems of inability to adjust the cutting position, remaining pits, and inefficient pitting machinery, etc., to assist in adjusting the angle and rotation of apples. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

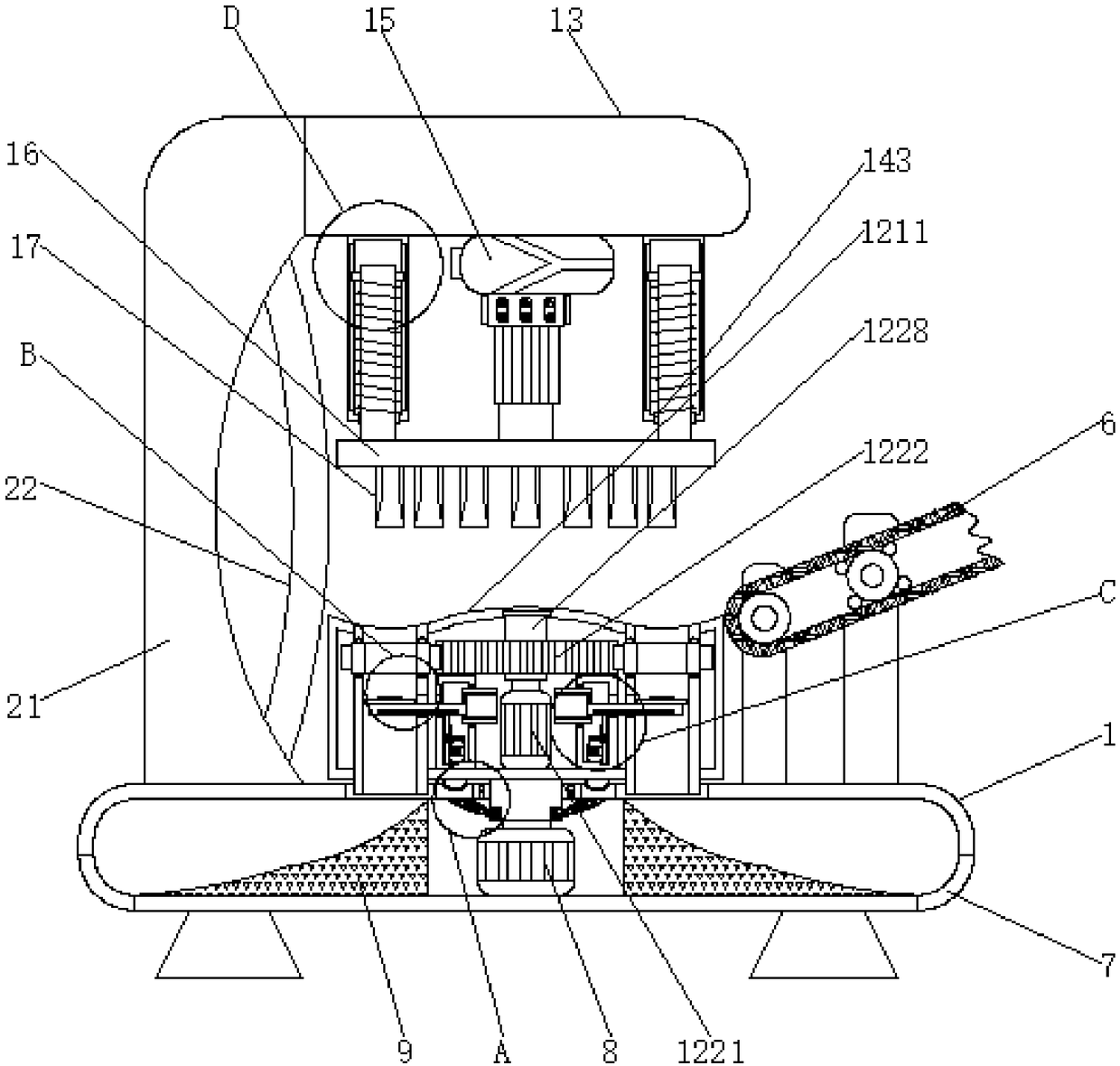

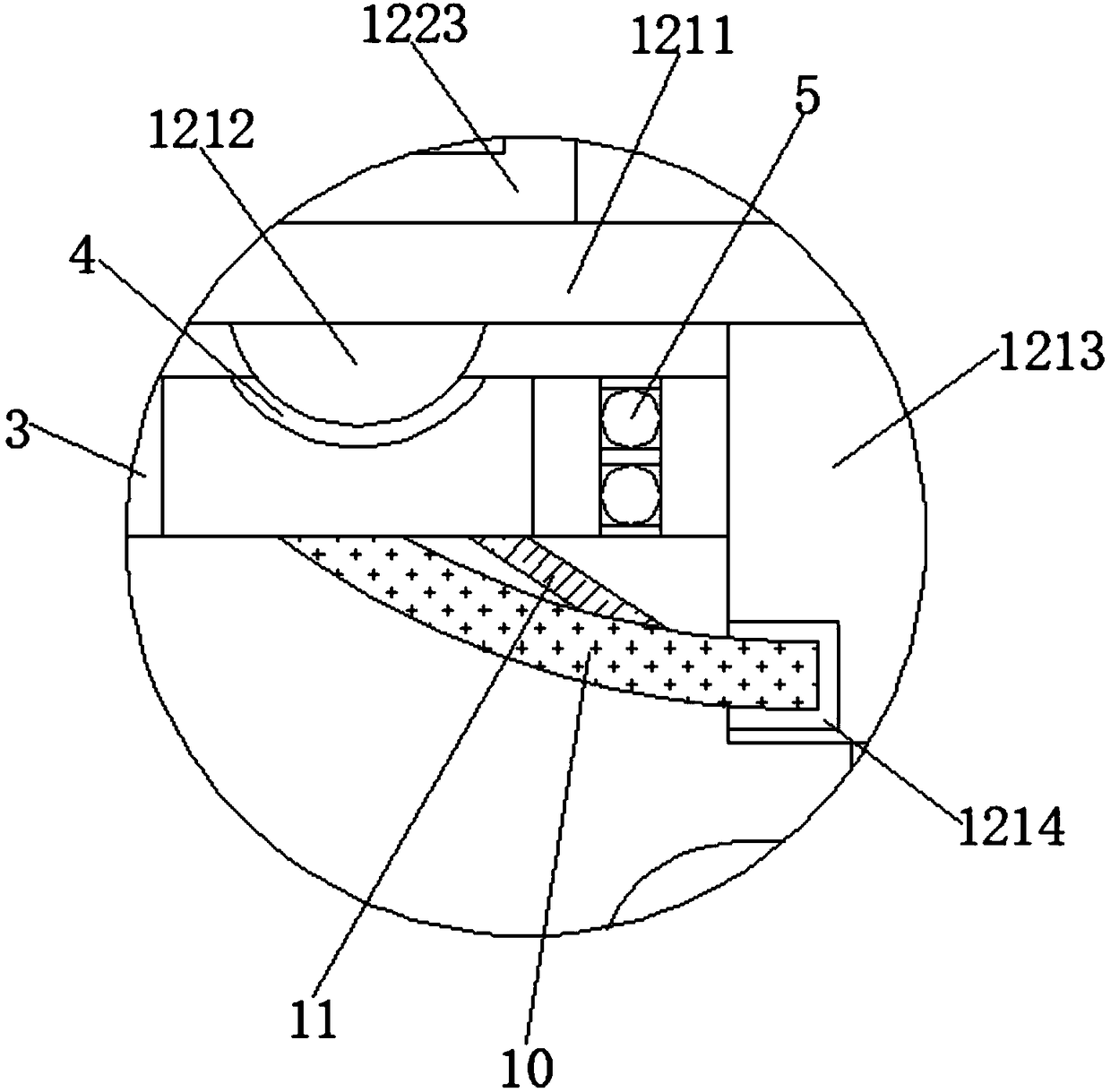

[0031] Such as figure 1 , 2 , shown in 5, a kind of apple deep processing based on dynamic friction removes the core of apple, comprises bearing platform 1, and one side of bearing platform 1 top is fixedly connected with supporting device 2, and the four sides of bearing platform 1 top are provided with annular feeding Port 3, the four sides at the center of the top of the load-bearing platform 1 are provided with an annular support groove 4, the center of the top of the load-bearing platform 1 is provided with a first opening, and the first opening is fixedly connected with the first bearing 5, and the other side of the top of the load-bearing platform 1 The belt transmission device 6 is fixedly connected, the bottom of the four sides of the load-bearing platform 1 is provided with an annular discharge port 7, the middle of the bottom of the inner wall of the load-bearing platform 1 is fixedly connected with a first motor 8, and the four sides of the bottom of the inner wall...

Embodiment 2

[0034] Such as figure 1 As shown, on the basis of Embodiment 1, the diversion fixing mechanism 12 includes a supporting mechanism 121, an adjusting mechanism 122 and a pressure-bearing sorting mechanism 123. The supporting mechanism 121 includes a processing box 1211, and the two sides in the center of the bottom of the processing box 1211 are symmetrically fixedly connected. There is a support ball 1212, and the center of the bottom of the processing box 1211 is fixedly connected with a transmission column 1213, and the bottom of the four sides of the transmission column 1213 is provided with annular limiting grooves 1214.

Embodiment 3

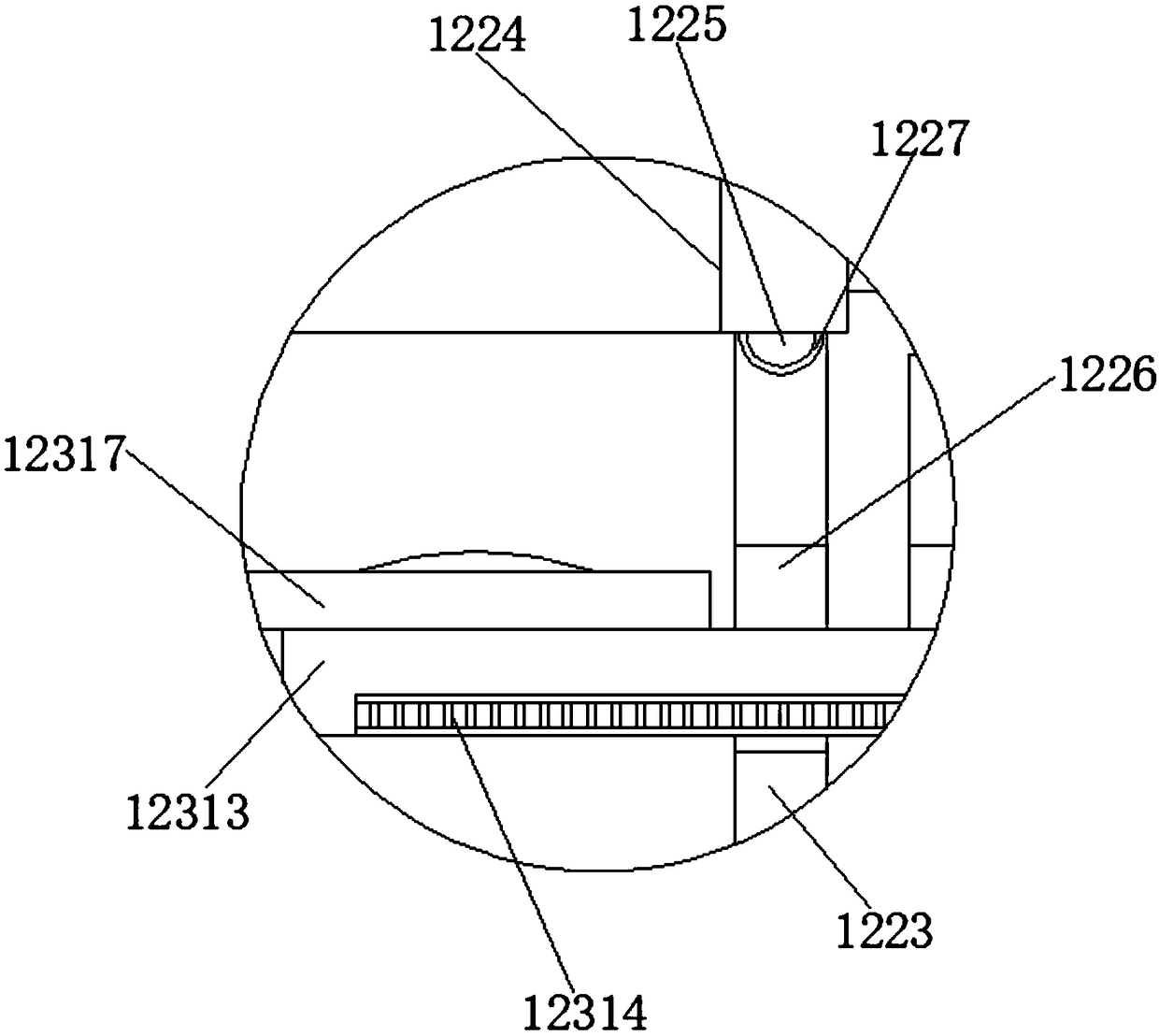

[0036] Such as figure 1 , 3 As shown, on the basis of Embodiments 1 and 2, the adjustment mechanism 122 includes a second motor 1221, the center of the top of the second motor 1221 is fixedly connected with a rotating shaft 1228, and the top of the rotating shaft 1228 is fixedly connected with a first gear 1222. The two sides of the motor 1221 are symmetrically provided with feeding pipes 1223, the top of the feeding pipe 1223 is sleeved with an adjusting sleeve 1224, the middle part of the outside of the adjusting sleeve 1224 is fixedly connected with gear teeth, and the two sides of the top and bottom of the adjusting sleeve 1224 are symmetrically fixedly connected There are sliding balls 1225, and the middle part of the opposite side of the adjustment sleeve 1224 is provided with a first moving groove 1226, the adjustment sleeve 1224 penetrates the outer wall of the delivery tube 1223 and extends to the inside of the delivery tube 1223, and the delivery tube 1223 is close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com