Laser annealing device and annealing method therefor

A laser annealing and annealing technology, which is applied to laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of silicon wafer surface exceeding, reducing the silicon wafer lithography effect and stability, and damage to workpiece table components, etc., to achieve improved Effect of annealing temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to make the purpose and features of the present invention more obvious and understandable, the specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments.

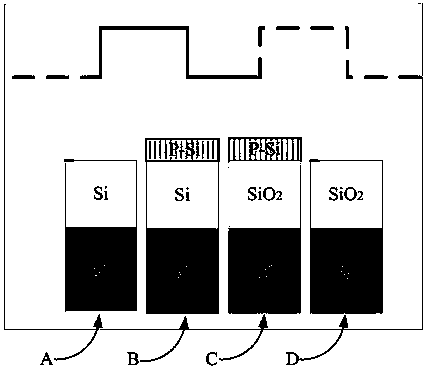

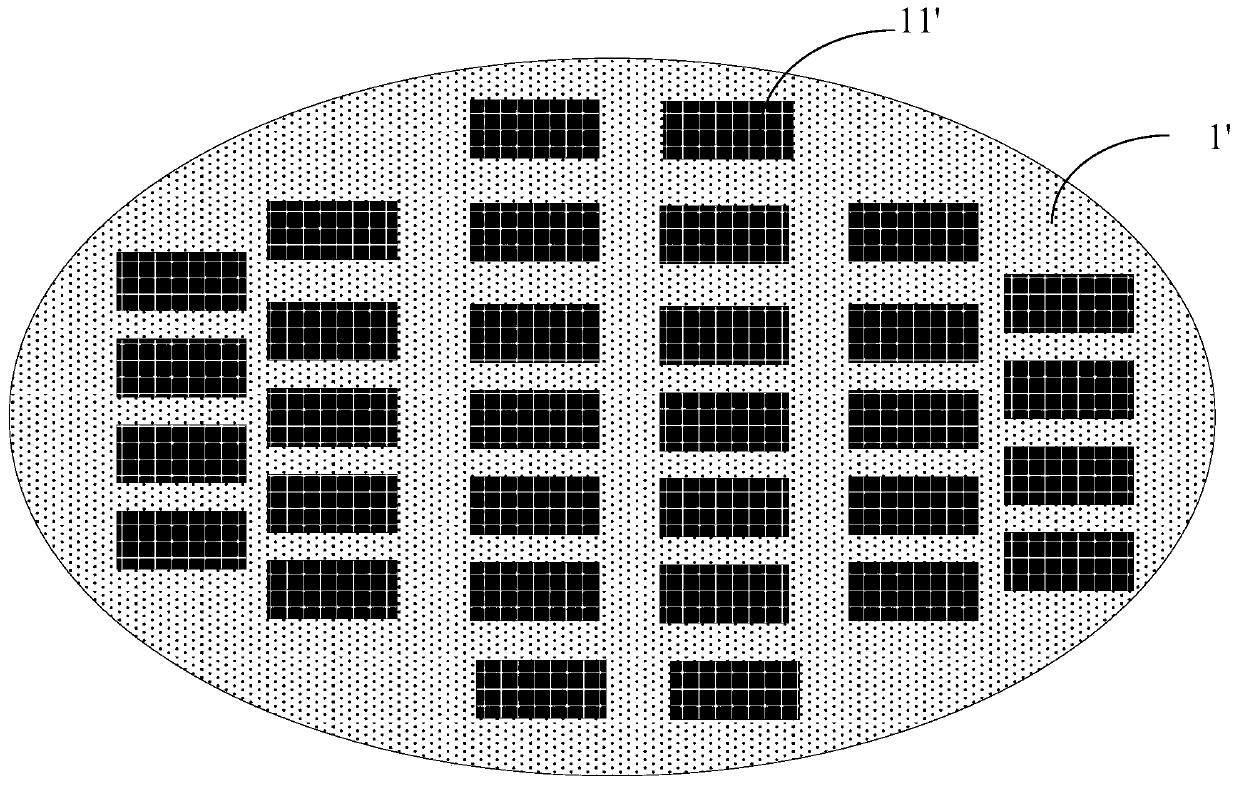

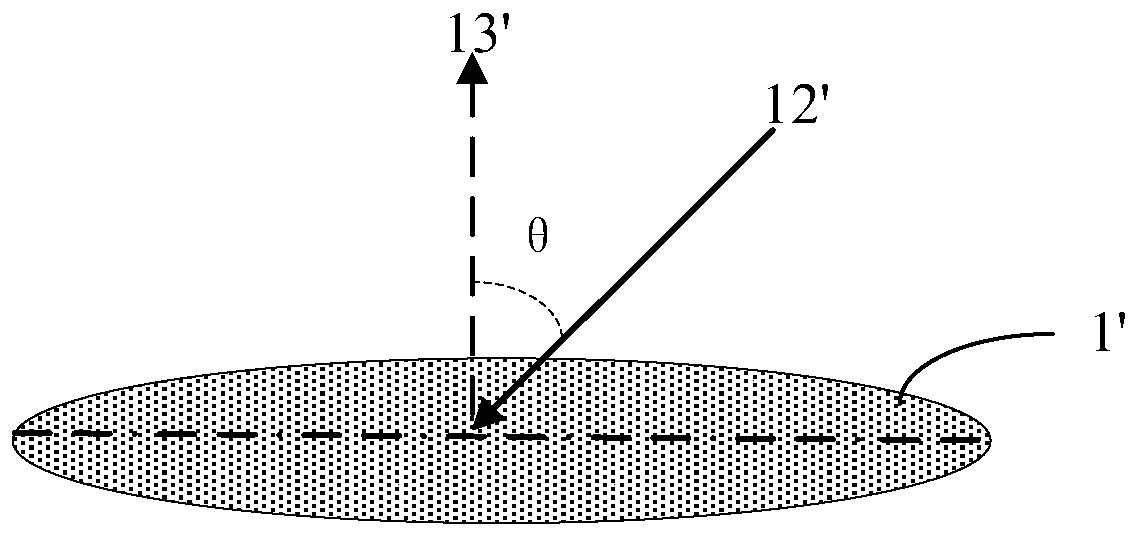

[0071] Please refer to Figure 4 to Figure 6 , the laser annealing device provided by the present invention mainly includes: the main frame of the equipment 000, the laser light source system 001 emitting the preheating laser beam 005 and the annealing laser beam 006, and the active shock absorption platform 002 for carrying the workpiece 004 to be annealed (such as 003, workpiece protection ring 010, ambient air filter 011, purification gas purging device 012, workpiece preheating platform 013, workpiece cooling platform 014, laser adjustment system 015 , slide stage movement system 016, measurement system and centra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com