A method of annealing a plate using a coiled material vertical vacuum annealing furnace

A technology for vacuum annealing furnaces and plates, applied in furnaces, furnace types, heat treatment furnaces, etc., to reduce temperature gaps, reduce temperature stabilization time, and improve annealing temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment includes the following steps:

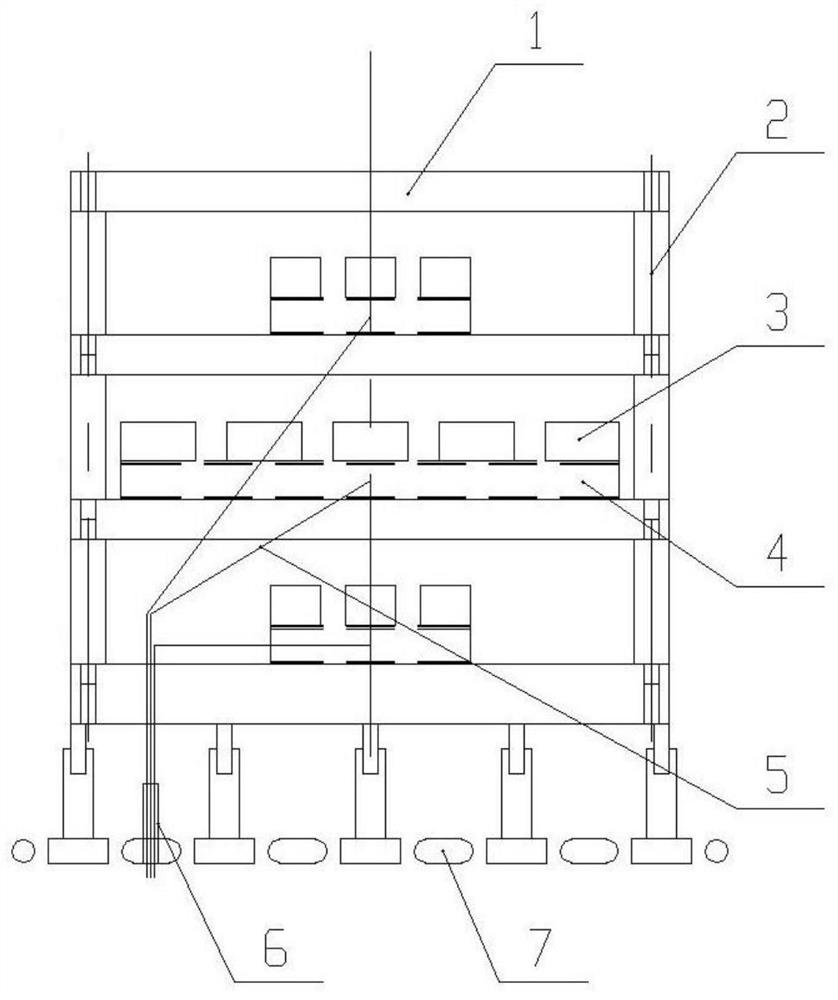

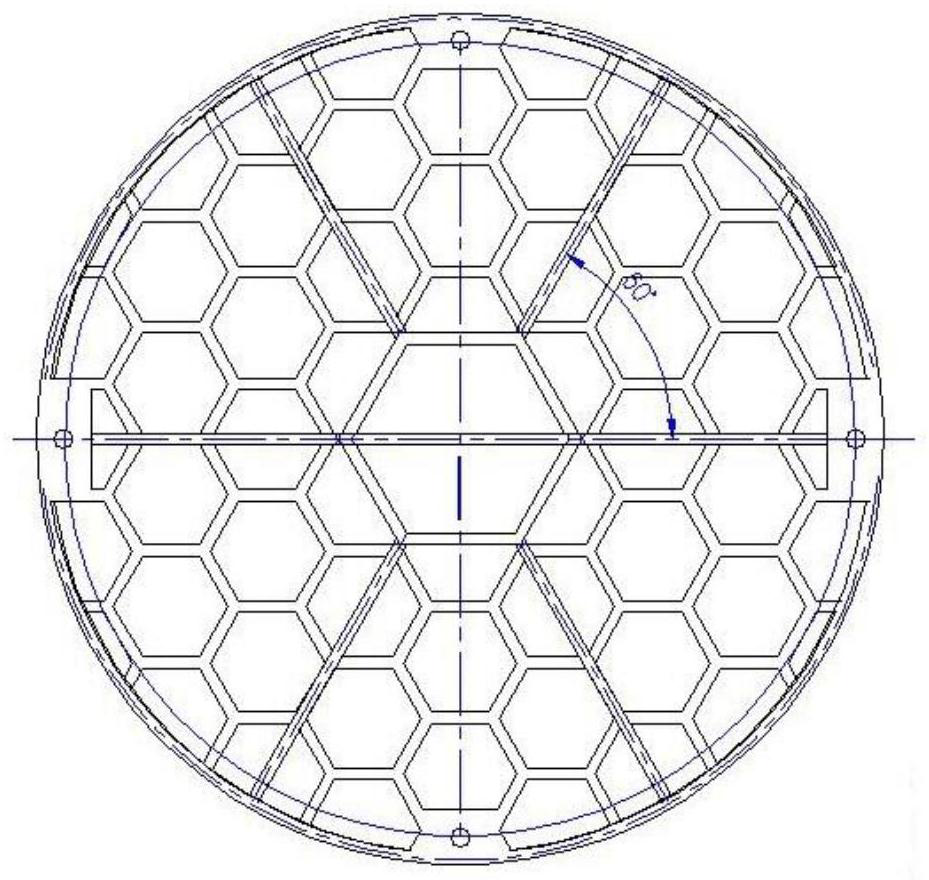

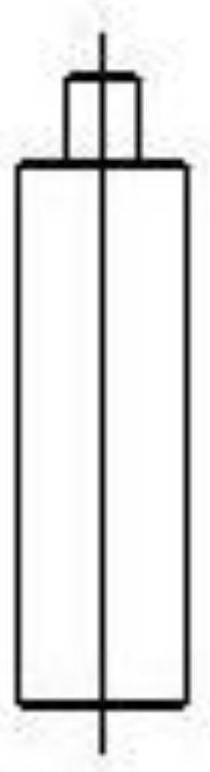

[0044] Step 1. According to the uniform temperature zone specifications of the coil vertical vacuum annealing furnace chamber, the characteristics of the heating method and the overall layout of the radiation heating zone, design and manufacture a special tooling suitable for the coil vertical vacuum annealing furnace chamber; the coil The standard diameter×height of the uniform temperature zone of the vertical vacuum annealing furnace is 1200mm×1200mm. The heating method is characterized by the combination of lateral radiation heating and top and bottom auxiliary heating. The overall layout of the radiation heating zone is a vertical cylinder; the special The three layers of detachable trays in the tooling are all grid structures, and the bottom of each layer of trays is provided with grooves, and support columns are arranged between adjacent trays, and the tops of the support columns are in contact with the adjacent trays...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that: the height of the support column in step 1 is 150mm; the temperature of the vacuum annealing process in step 5 is 550°C, and the holding time is 1.5h; the heating rate is set to 2 in step 6. ℃ / min, set the output power difference as 55%.

Embodiment 3

[0054] The difference between this example and Example 1 is that the height of the support column in step 1 is 350mm; the temperature of the vacuum annealing process in step 5 is 620°C, and the holding time is 3h; the heating rate is set at 8°C in step 6 / min, set the output power difference as 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com