Device and method for tempering several process goods

A treatment and annealing technology, used in heat treatment furnaces, heat treatment equipment, lighting and heating equipment, etc., can solve problems such as damage to treatment objects, and achieve the effect of achieving heating rate and improving temperature uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

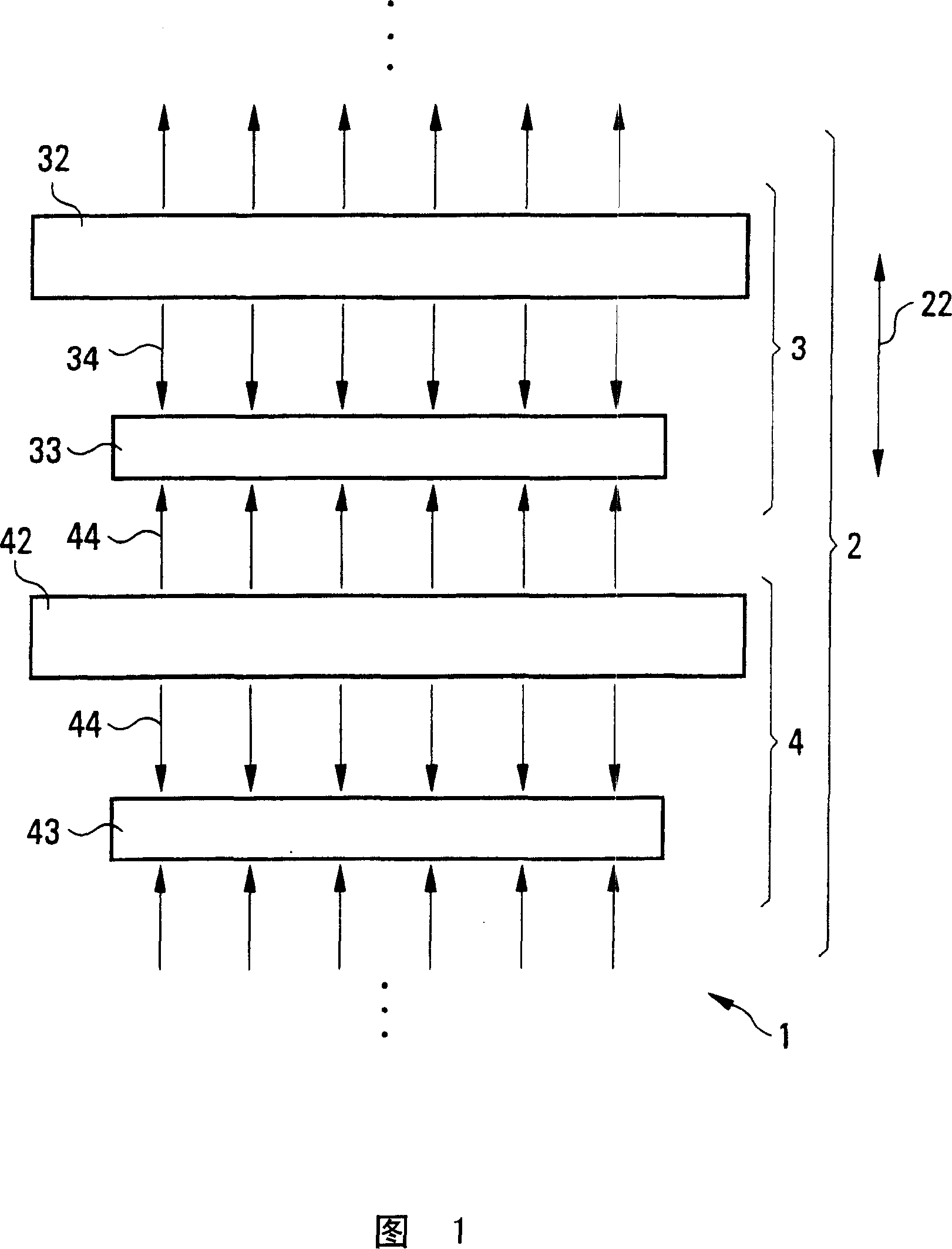

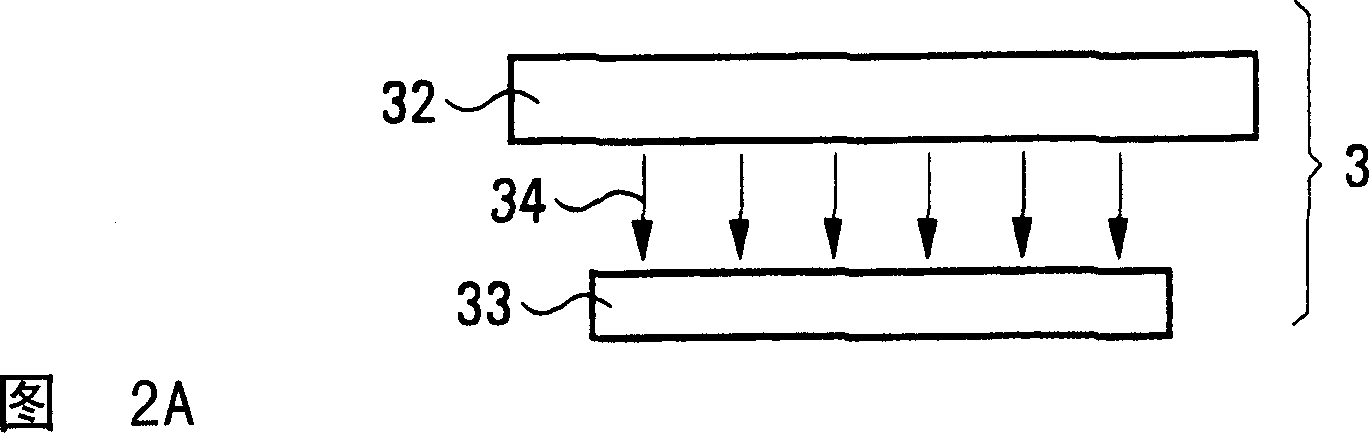

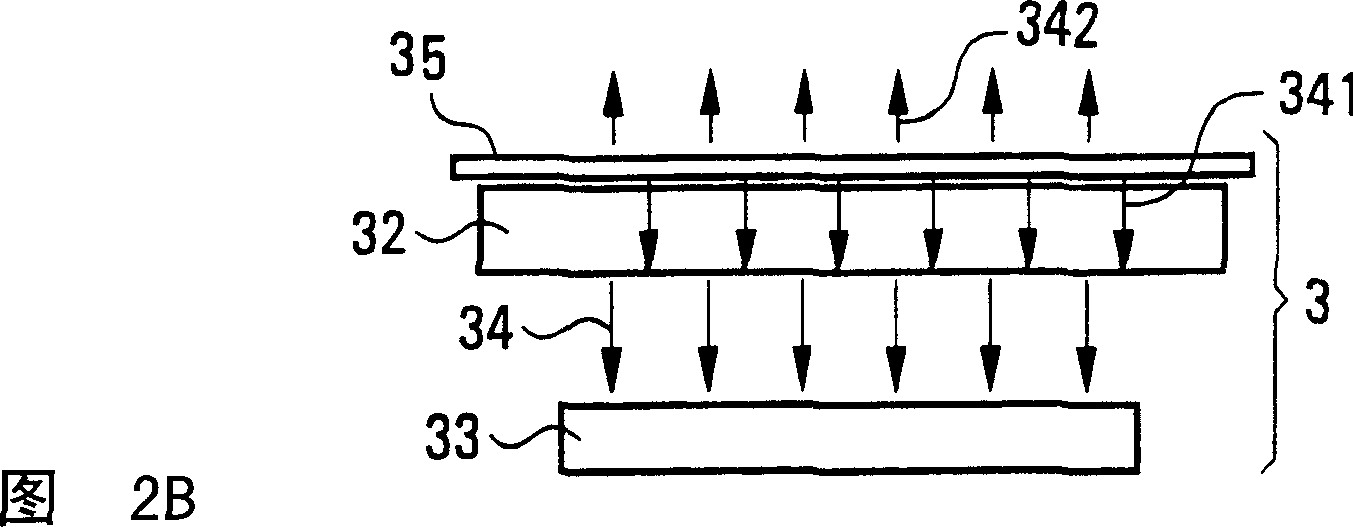

[0126] The starting point is an apparatus 1 ( FIG. 1 ) for annealing various treatments 33 and 43 . The device described consists of a plurality of tempering units 3 and 4 arranged one above the other to form a tempering stack 2 . A tempering unit 3 or 4 has an energy source 32 or 42 . For annealing the treatment material, the energy source and the treatment material are arranged so close to each other that the treatment material 33 is arranged between the energy source 32 and the other energy source 42 in a certain stack direction 22 of the annealing stack 2 , whereas The further energy source 42 described is arranged between the processed object 33 and the further processed object 43 .

[0127] In one implementation the energy sources 32 or 42 are rod-shaped halogen lamps 61 arranged in an array 64 (FIG. 6). Each of the halogen lamps 6 of the array 64 is arranged in an envelope 60 made of quartz glass. A liquid or gaseous coolant 62 flows through the interspace between en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com