Fully automatic continuous annealing system for amorphous strip

An amorphous strip material and fully automatic technology, applied in the field of fully automatic systems, can solve the problems of manpower consumption, poor consistency, and low work efficiency, and achieve the effects of reducing the number of times of overshooting temperature, achieving poor consistency, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

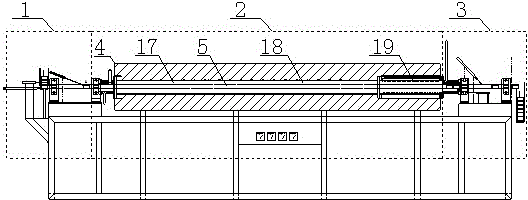

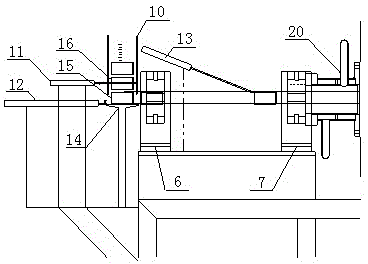

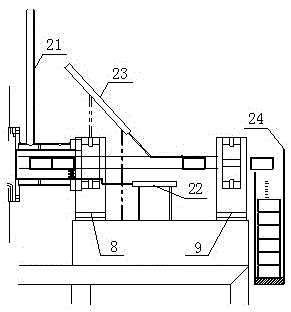

[0039] The technical solution of this embodiment is: a fully automatic amorphous strip continuous annealing system, mainly composed of a feeding part 1, a heat treatment part 2, a feeding part 3 and a control part, the feeding part 1 and the feeding part 3 are respectively Located on the left and right sides of the heat treatment part 2; the heat treatment part 2 includes an annealing furnace 4; a metal rod 5 is arranged in the annealing furnace 4 and extends transversely through the furnace, and four valves for fixing the metal rod 5 are arranged outside the annealing furnace 4 ; The feeding part 1 is used to cover the amorphous strip on the metal rod 5 and is sent into the annealing furnace 4, the heat treatment part 2 is used to heat the amorphous strip, add a magnetic field and cool it, and the retrieving part 3 is used After the amorphous strip is taken out from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com