Pin neck receptacle for hubs, in particular in rolling mills

An accommodating part and pin neck technology, which is applied to the driving device of metal rolling mill, metal rolling, mechanical equipment, etc., can solve the problems of limiting the service life of the hub together with the pin neck accommodating part, and the reprocessing of the pin neck accommodating part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

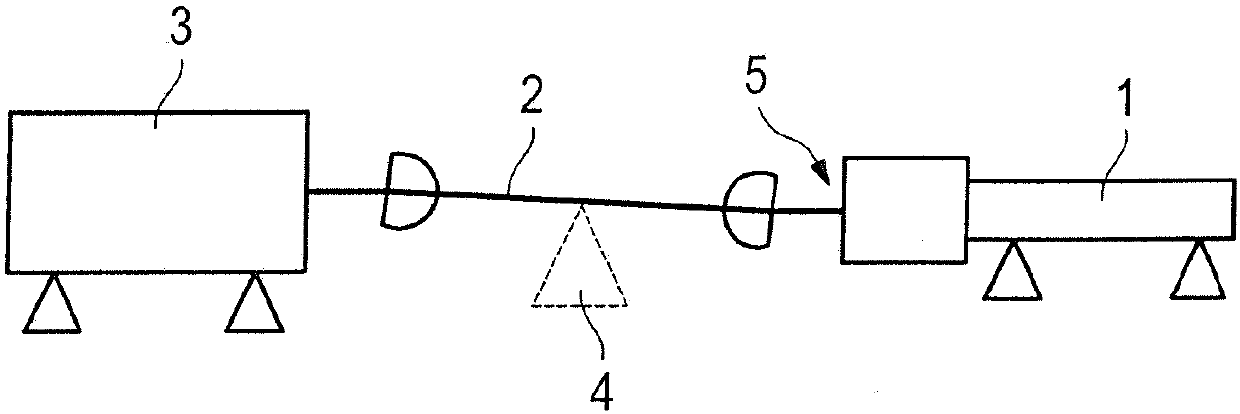

[0023] exist figure 1 shows a rolling mill or a rolling mill drive train in which a roll 1 , also called a work roll, is driven via a cardan shaft 2 with two cardan joints by means of a motor 3 in the form of an electric motor. The cardan shaft 2, in particular embodied as a universal joint shaft, is supported by means of bearings 4 and is mounted via the figure 2 The roller drive connection 5 described in detail in is connected to the roller 1 .

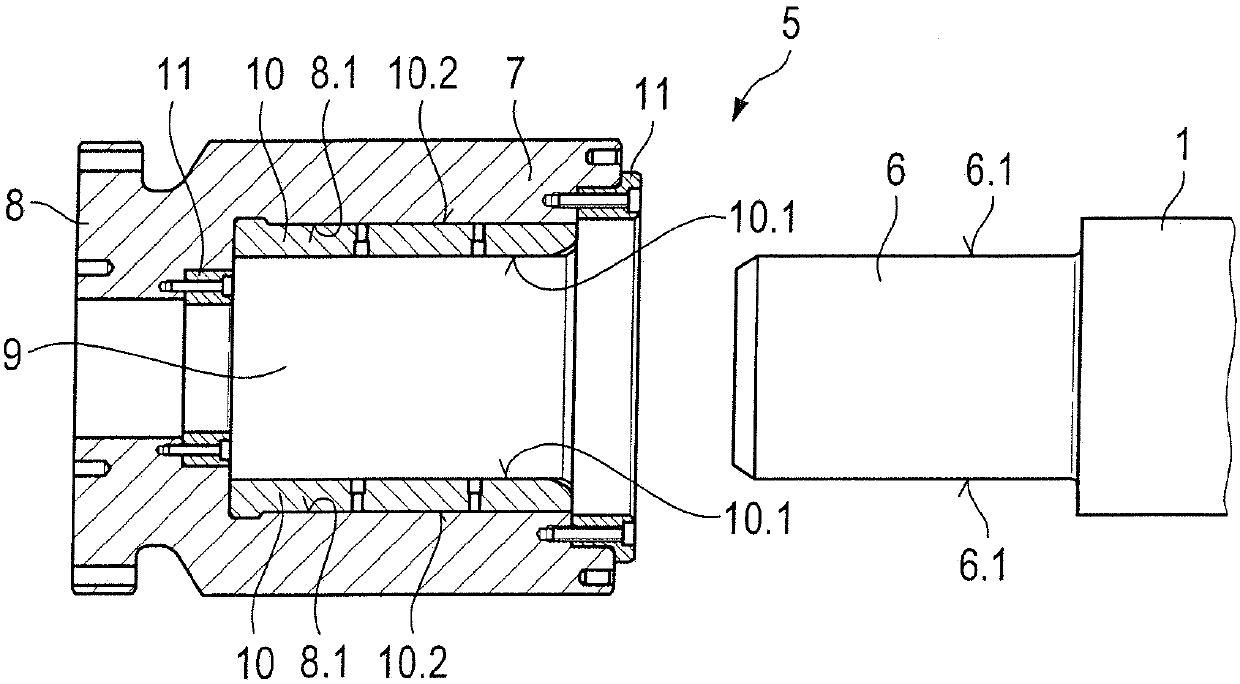

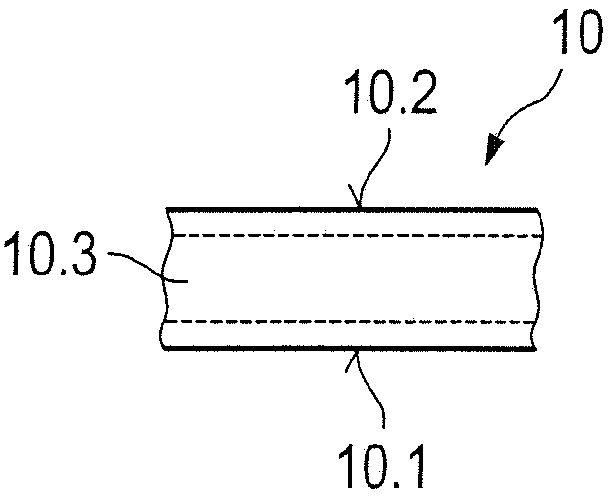

[0024] exist figure 2 It can be seen in the roller transmission connection part 5, which consists of the pin neck 6 of the roller 1 and the universal joint shaft (in figure 2 (not shown in ) or the corresponding hub of the cardan shaft constitutes the pin neck receptacle 7 . The pin neck receptacle 7 has a base body 8 in which an opening 9 is arranged, into which opening the pin neck 6 of the roller 1 is introduced. Two wear linings 10 are inserted opposite each other into the opening 9 in such a way that they delimit the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com