A kind of processing method of spring sheet for tuning fork type crystal resonator

A technology of crystal resonators and processing methods, applied in chemical instruments and methods, cleaning methods using liquids, molding tools, etc., to achieve the effects of reduced energy consumption, clean surfaces, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment one:

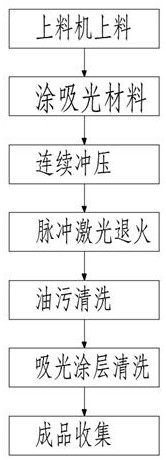

[0039] A method for processing a spring sheet for a tuning fork crystal resonator:

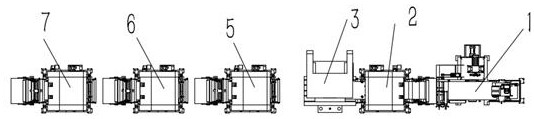

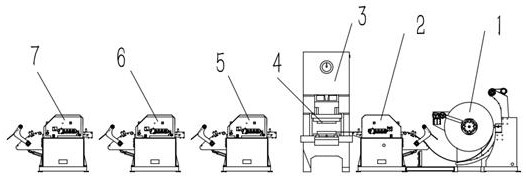

[0040] The first step is to unfold the material belt, fix the coiled zinc-nickel-nickel copper material belt on the feeding machine 1 and use the feeding machine to unfold it. The feeding machine is a fully automatic feeding device integrating feeding, straightening and material rack. General-purpose equipment for continuous stamping and automatic feeding, which will not be repeated here;

[0041] The second step is to coat the light-absorbing material coating, and set the light-absorbing material coating device 2 at the outlet of the flattened zinc-nickel-nickel copper material strip of the feeder 1. Roller, the interior of the roller is a cavity structure, and the end of the roller is connected with the liquid material cylinder of the light-absorbing material. When the zinc nickel copper strip passes through the space between the two rollers, the two rollers rotate ...

Embodiment 2

[0048] Embodiment two:

[0049] A method for processing a spring sheet for a tuning fork crystal resonator:

[0050] The first step is to unfold the material belt, fix the coiled zinc-nickel-nickel copper material belt on the feeding machine 1 and use the feeding machine to unfold it. The feeding machine is a fully automatic feeding device integrating feeding, straightening and material rack. General-purpose equipment for continuous stamping and automatic feeding, which will not be repeated here;

[0051] The second step is to coat the light-absorbing material coating, and set the light-absorbing material coating device 2 at the outlet of the flattened zinc-nickel-nickel copper material strip of the feeder 1. Roller, the interior of the roller is a cavity structure, and the end of the roller is connected with the liquid material cylinder of the light-absorbing material. When the zinc-nickel-nickel material strip passes through the space between the two rollers, the two roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com