Martensitic stainless steel with high Mn content

A martensitic stainless steel, content technology, applied in the field of martensitic stainless steel, can solve the problems of increasing production cost and increasing the difficulty of production and manufacturing, and achieve the effect of outstanding corrosion resistance, excellent mechanical properties and reduced process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

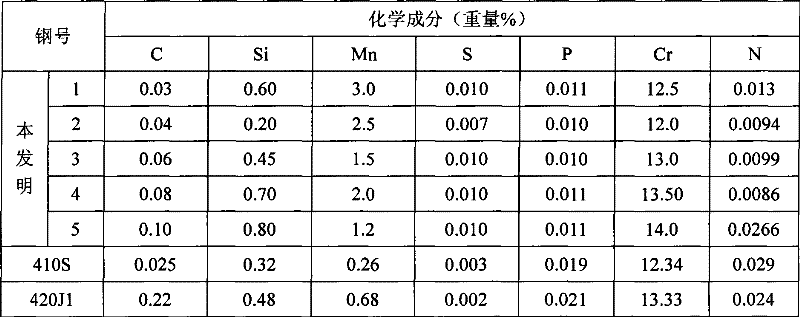

[0032] Table 1 Similar Patent Steel Composition Control Comparison (Wt%)

[0033] Patent No C Si mn P S Cr Ni Mo Cu Ti Nb CN1697889 0.03-0.1 ≤0.5 1-2.5 — — 10-15 — — — 0.01-0.5 0.01-1.0 Wo2007029626 0.05-0.1 0.1-1.0 0.2-2 ≤0.04 ≤0.01 11-14 0.5-2 1-2 0.5-2 ≤0.1 0.03-0.3 this invention 0.03-0.1 0.2-0.8 1.2-3.0 ≤0.03 ≤0.02 12-14

[0034] Patent No V Zr Al Ta f N CN1697889 0.01-0.5 0.01-1.0 — ≤0.5 ≤0.5 0.005-(Ti+V)×14 / 50+(Nb+Zr)×14 / 90 Wo2007029626 - - ≤0.1 0.01-0.025 this invention 0.008-0.03

[0035] Among them, the 13Cr martensitic stainless steel (WO2007029626) applied by "The Thomson Corporation" adds Ni, Mo, Cu and other elements to improve the plasticity and toughness of the 13Cr martensitic stainless steel, and at the same time, the hardenability is also improved. It uses Ni to expand the high-temperature austenite region, uses Mo...

Embodiment 2

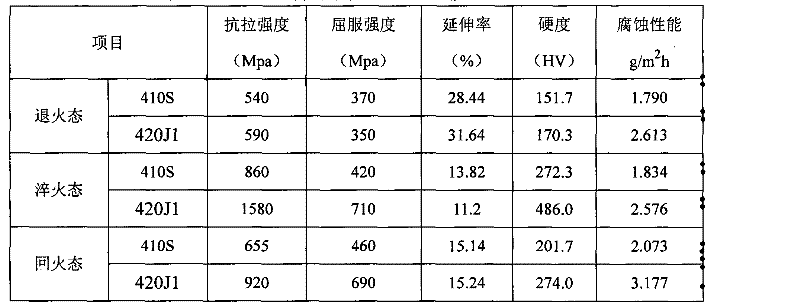

[0040] According to the chemical composition range designed by the present invention, 5 furnaces of steel were smelted on the vacuum induction furnace, which we named as No. 1 furnace, No. 2 furnace, No. 3 furnace, No. 4 furnace, and No. 5 furnace respectively. The chemical composition is shown in Table 2.

[0041] All the 5 furnaces of molten steel were poured into small steel ingots, and the steel ingots were sand-cooled with molds, and demoulded after cooling to room temperature. After demoulding, the surface of the ingot is ground and forged, and finally heated to 1200°C and hot-rolled into a plate. Sample processing is carried out on the plate according to the requirements of the national standard. The steel was annealed at 760°C and quenched at 1000°C respectively, and its strength, hardness, plasticity and corrosion resistance were tested. The corrosion resistance test adopts the salt spray corrosion method, and the corrosion period is 120 hours. The test results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com