A simple lifting platform

A lifting platform, simple technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of poor heat treatment quality, workpiece drop, inconvenient use, etc., and achieve the effect of stable and reliable lifting movement, easy disassembly and maintenance, and convenient and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

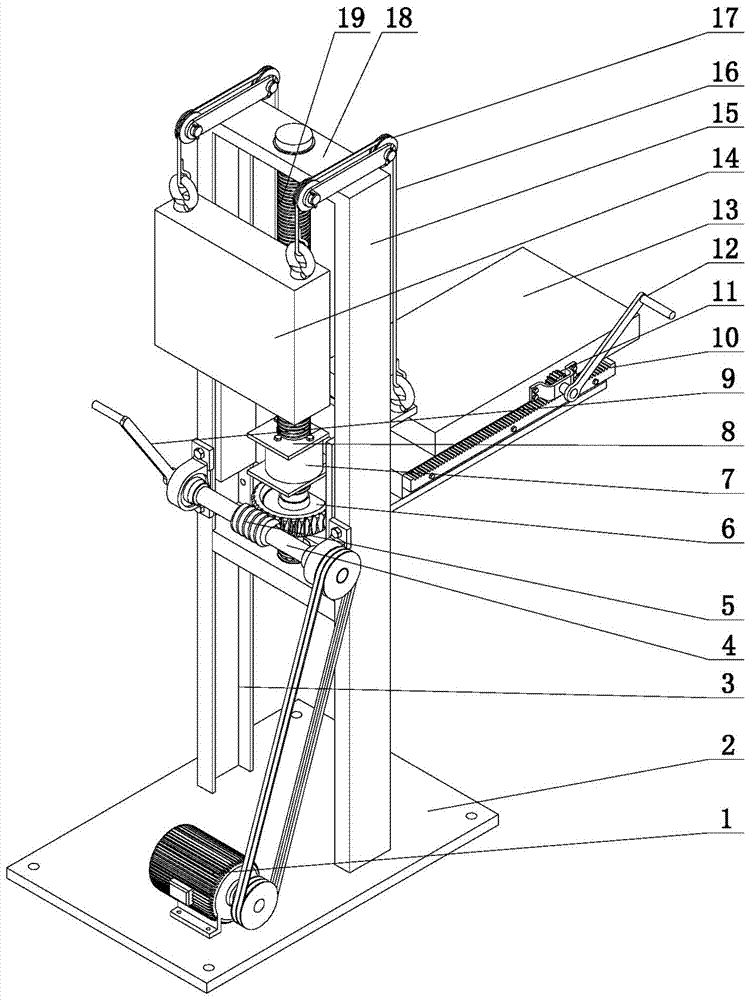

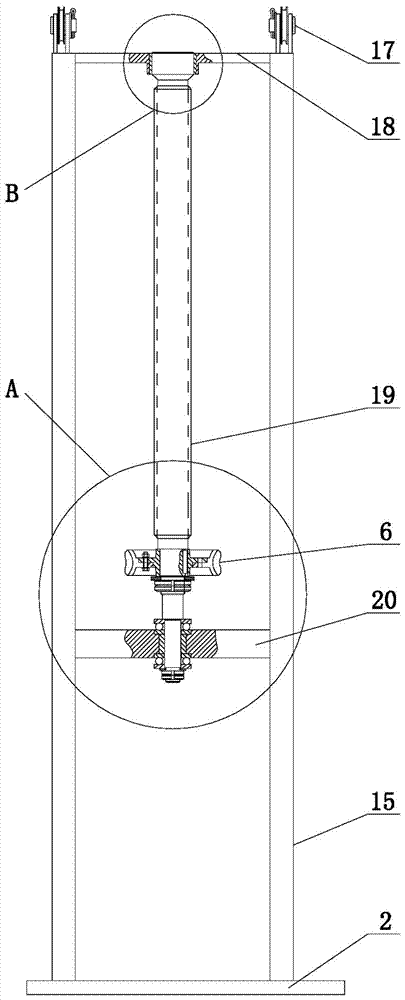

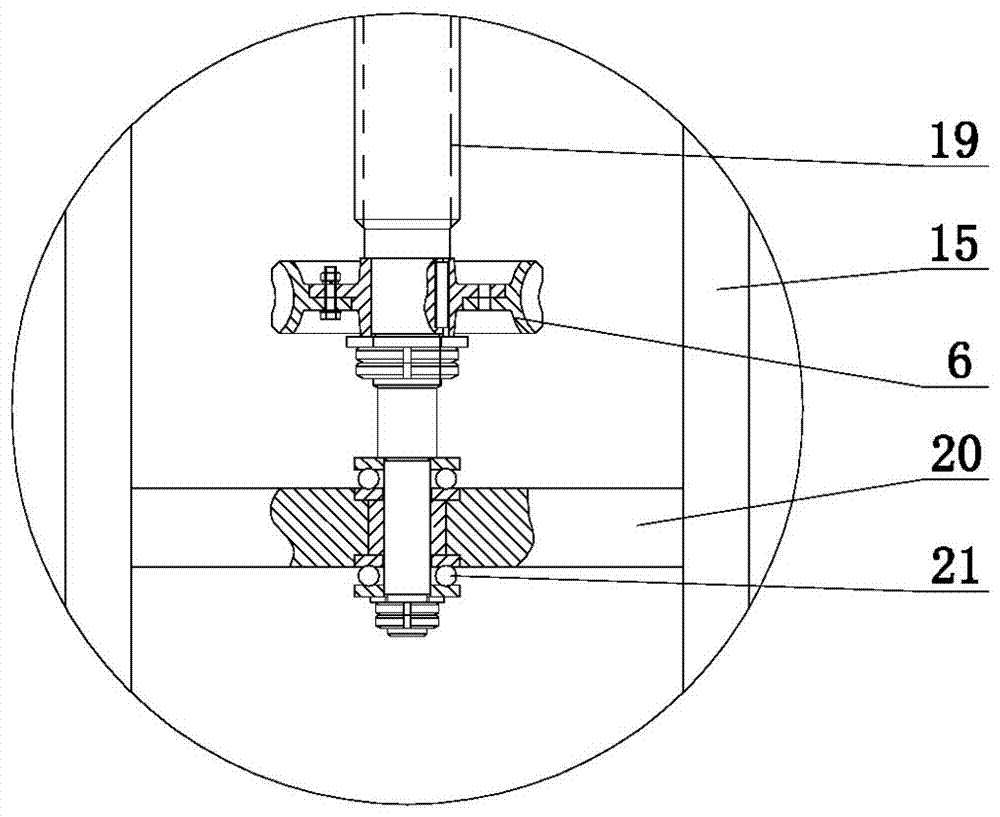

[0020] The present invention comprises base 2, and base 2 is provided with two trough-shaped columns 15, and crossbeam 18 is arranged between the top of two trough-shaped columns 15, is characterized in that: the groove 3 of described two trough-shaped columns 15 is oppositely arranged, and groove All be provided with the slide block 22 that cooperates with groove 3 in the groove 3 of shaped column 15; Described slide block 22 links to each other with the vertical edge 27 of the lifting frame 28 of same L shape; Described beam 18 below is provided with leading screw 19 , the lead screw 19 is provided with a screw nut 7, the screw nut 7 is provided with a connecting frame 8, and the vertical edge 27 of the L-shaped lifting frame 28 is provided with a connecting groove 26 matched with the connecting frame 8 ; The horizontal edge 29 of the lifting frame 28 is provided with a horizontal slide plate 13, and the horizontal sliding plate 13 is provided with a rotating gear 11; .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com