Flexible pressing wheel mechanism and self-adaptive laser welding device

A laser welding head and pressure wheel technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large volume, complex structure of laser pressing method, etc., and achieve small volume, simple structure, and deformation suppression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

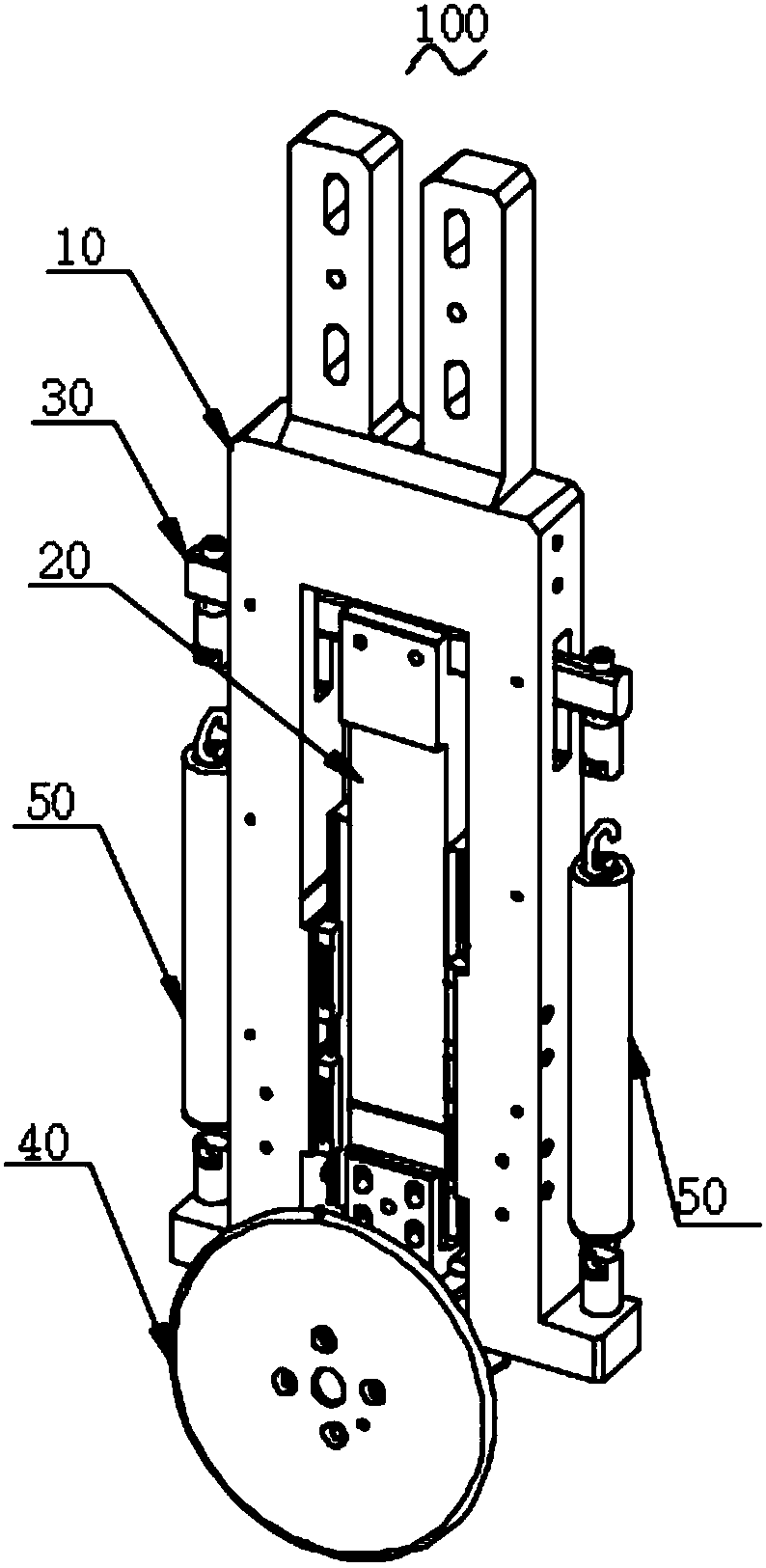

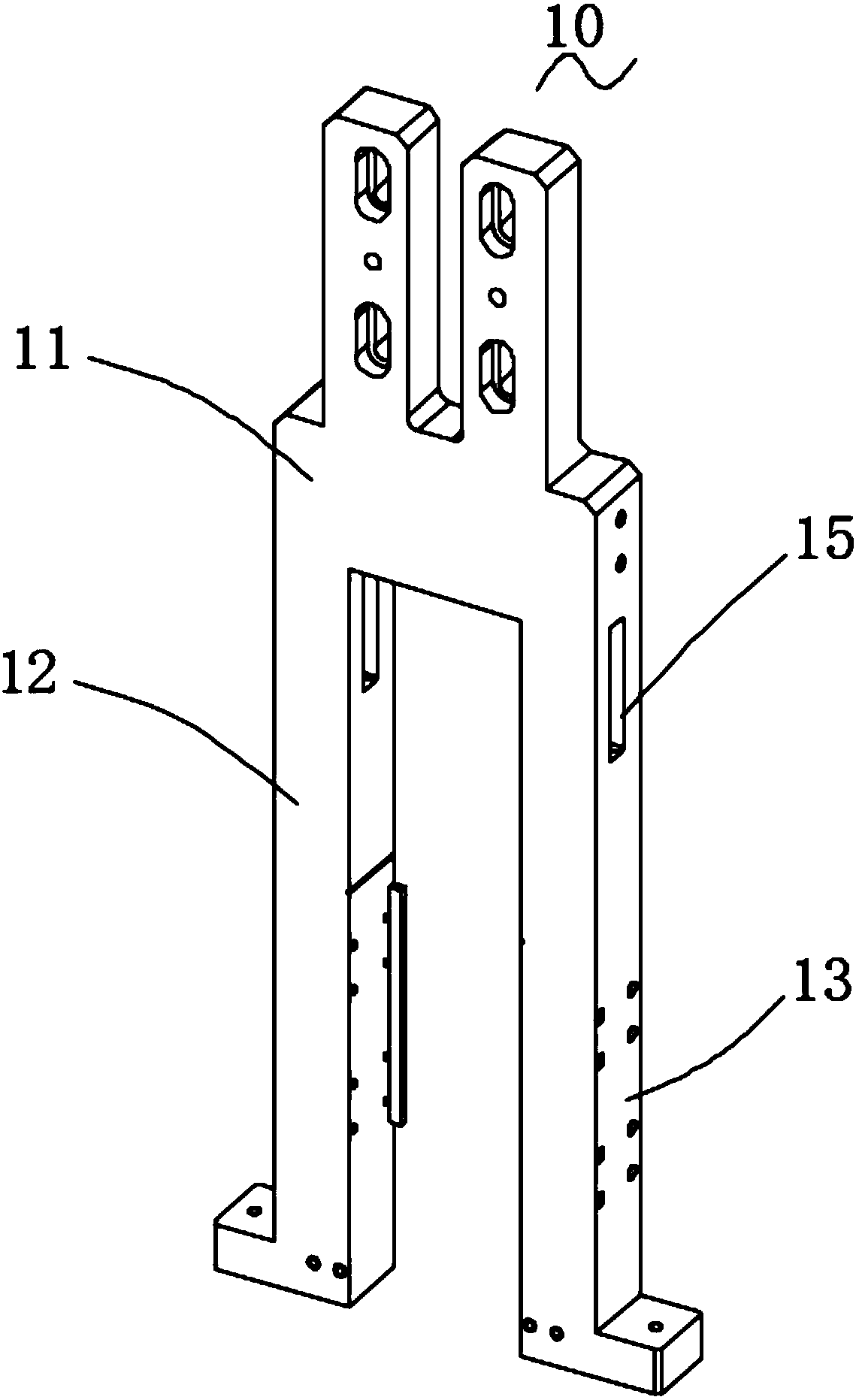

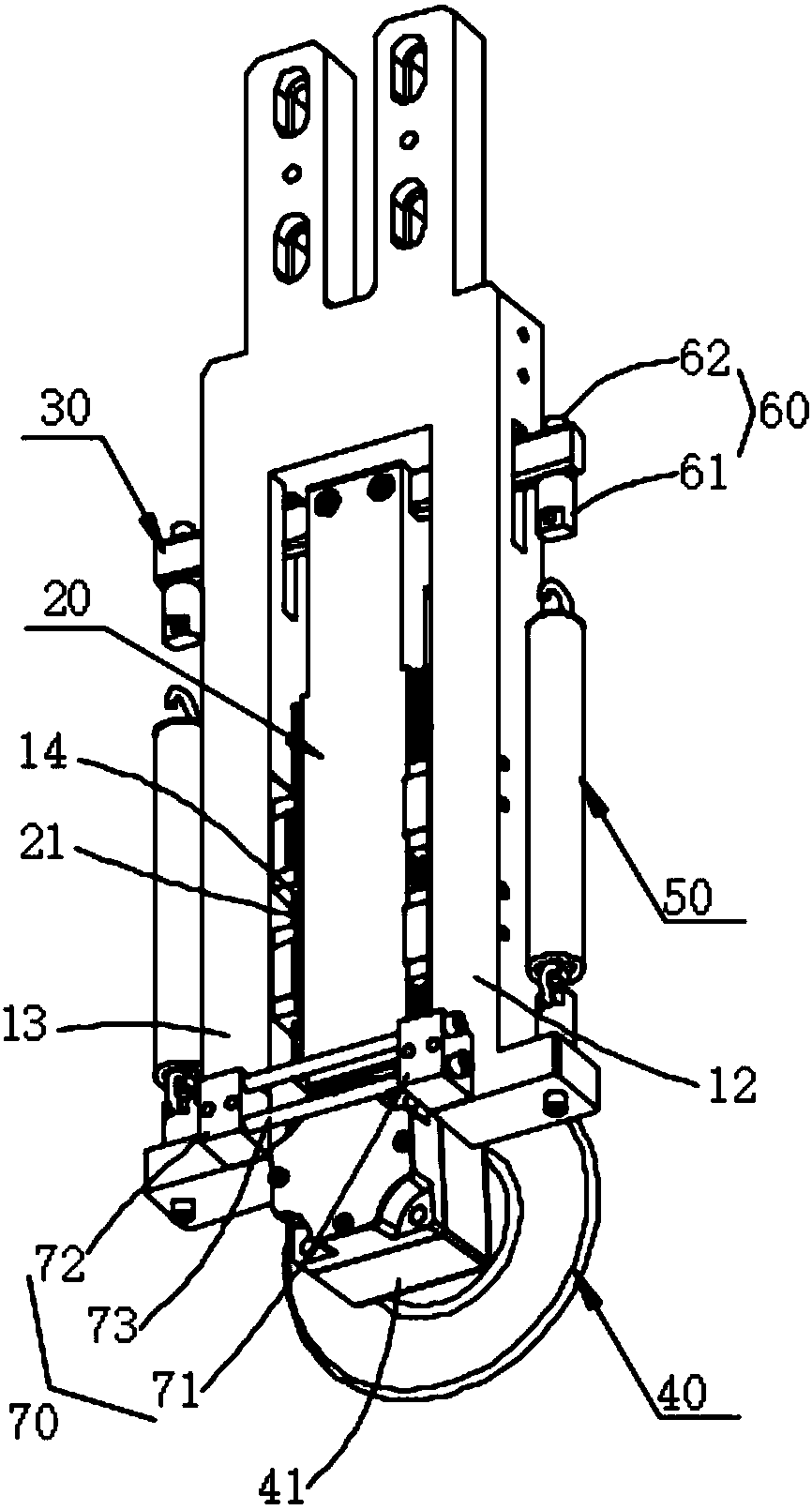

[0025] Such as figure 1 As shown, the present invention provides a flexible pressure wheel mechanism 100, which includes a fixed frame 10, a slide bar 20, a connecting rod 30, a pressure wheel 40 and two springs 50, and the pressure wheel 40 is installed at the bottom of the slide bar 20 in rotation. end, the connecting rod 30 is installed on the top of the sliding rod 20 and is perpendicular to the sliding rod 20, the sliding rod 20 can slide up and down and is installed on the fixed frame 10, and one of the springs 50 is respectively connected to one end of the connecting rod 30 and the fixed frame 10, and another spring 50 is respectively connected to the other end of the connecting rod 30 and the fixed frame 10; when the sliding rod 20 moves up, the spring 50 is stretched. A flexible mechanism 100 of the present invention has a simple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com