Automatic cleaning and cutting machine for agricultural wheat straw utilization

An automatic cleaning and cutting machine technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of low wheat straw processing efficiency and increased wheat straw processing cost, and achieve the goal of avoiding increased workload, reducing processing costs and increasing income. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

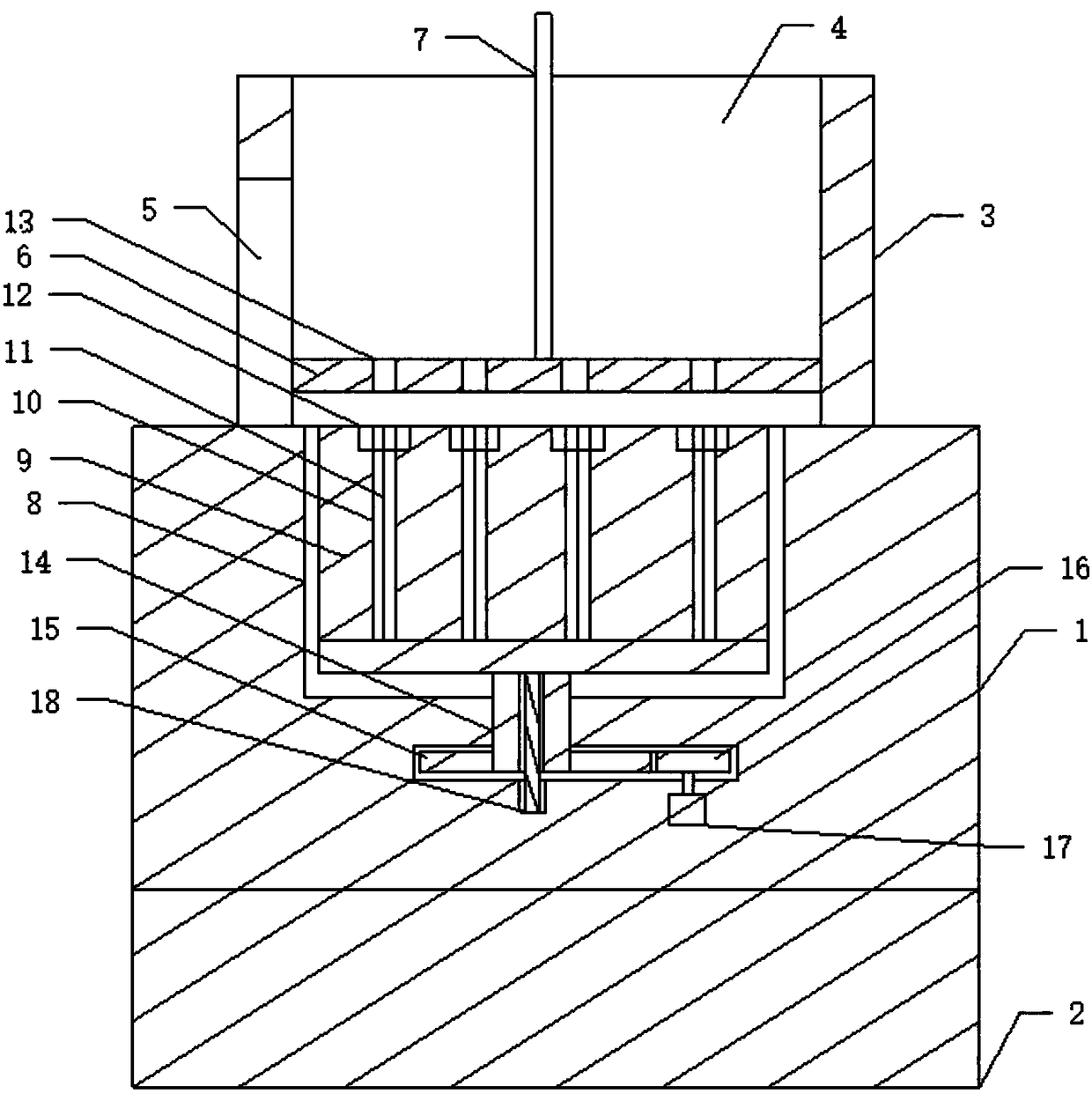

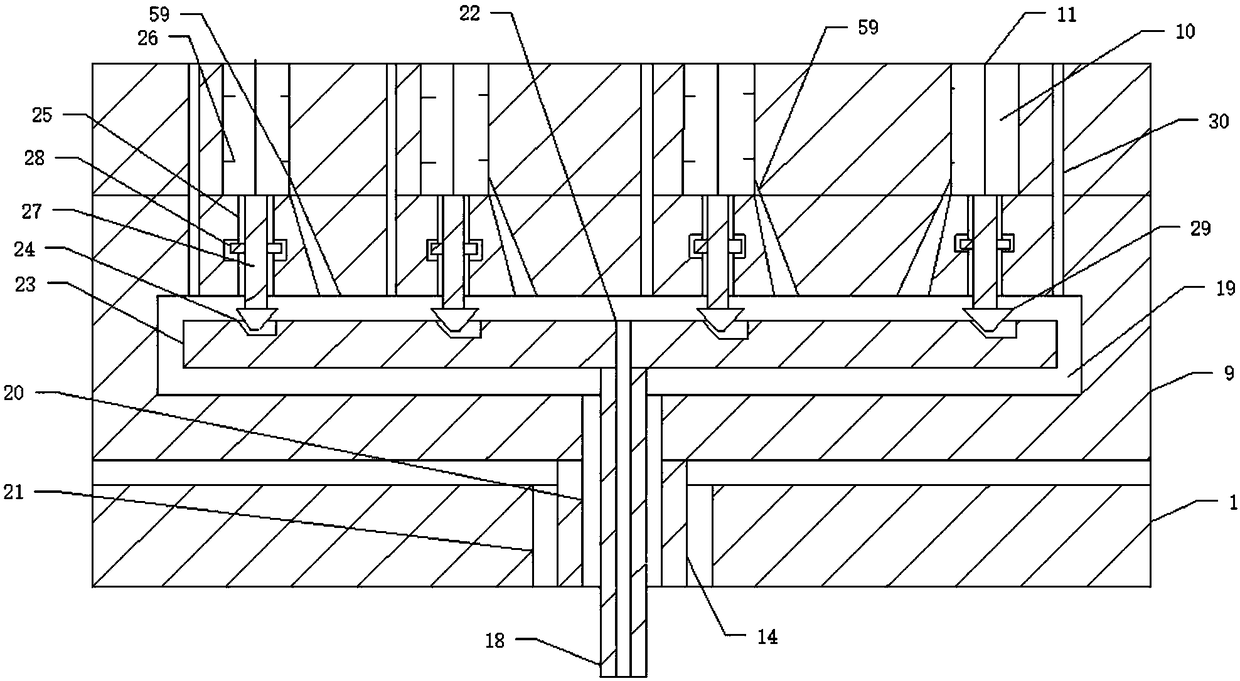

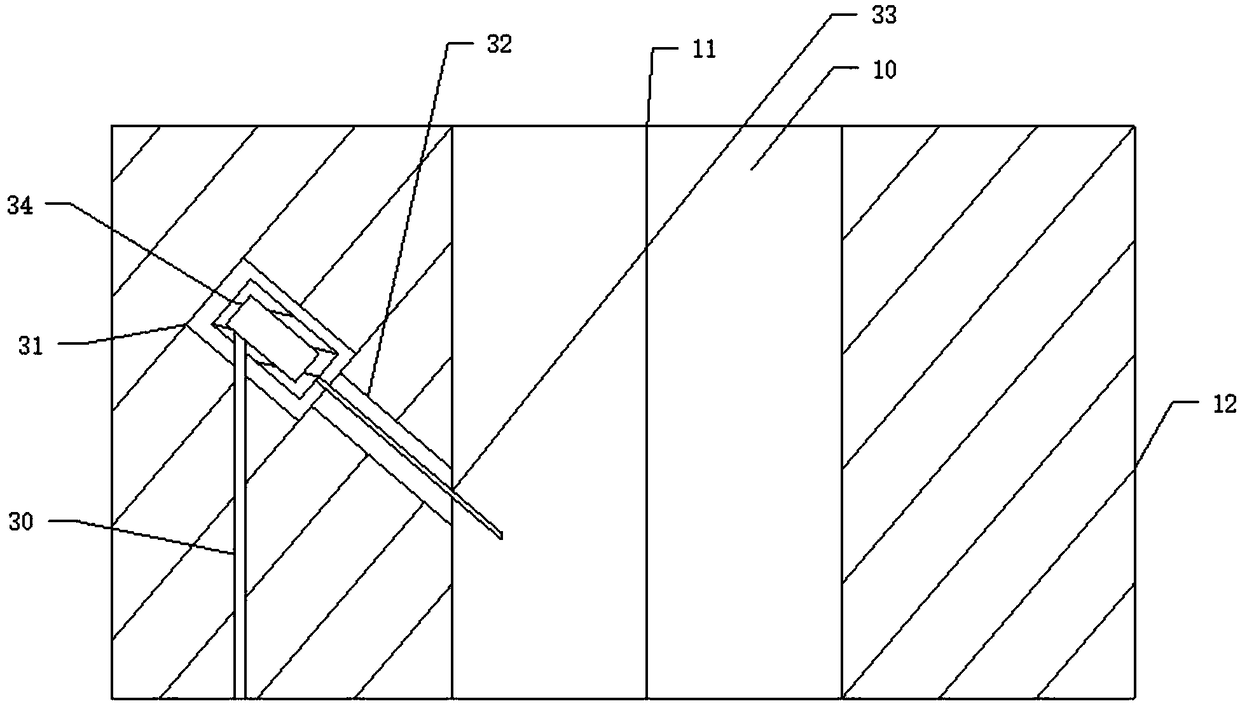

[0032] Such as Figure 1 to Figure 6 As shown, an agricultural straw cutting machine using automatic cleaning includes a straw cutting module 2, a straw feeding groove 40 is arranged in the straw cutting module 2, and a straw feeding groove 40 is arranged in the straw cutting module 2. There is a straw chute 43 corresponding to the straw inlet trough 40 , a fifth rotating shaft 52 is arranged inside the straw cutting module 2 , and two rotating shafts are arranged on the fifth rotating shaft 52 . The cutting knife 42 rotating in the straw chute 43, the two cutting knives 42 can cut the straw equidistantly, and the straw cutting module 2 is also provided with one and two cutting knives 42 corresponding to the conveyor belt 46, the two sides of the straw cutting module 2 are respectively provided with a first port 55 corresponding to the straw chute 43, and the first port 55 on both sides A rotating exhaust vane 56 is provided respectively, and the fifth rotating shaft 52 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com