Waste plastic recovering method

A technology of waste plastic and recycling method, applied in the field of waste plastic recycling, can solve the problems of blockage of the feeding port, affecting the reuse of plastic, and inability to screen sand and gravel, so as to facilitate dust removal, increase utilization rate, and save electricity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

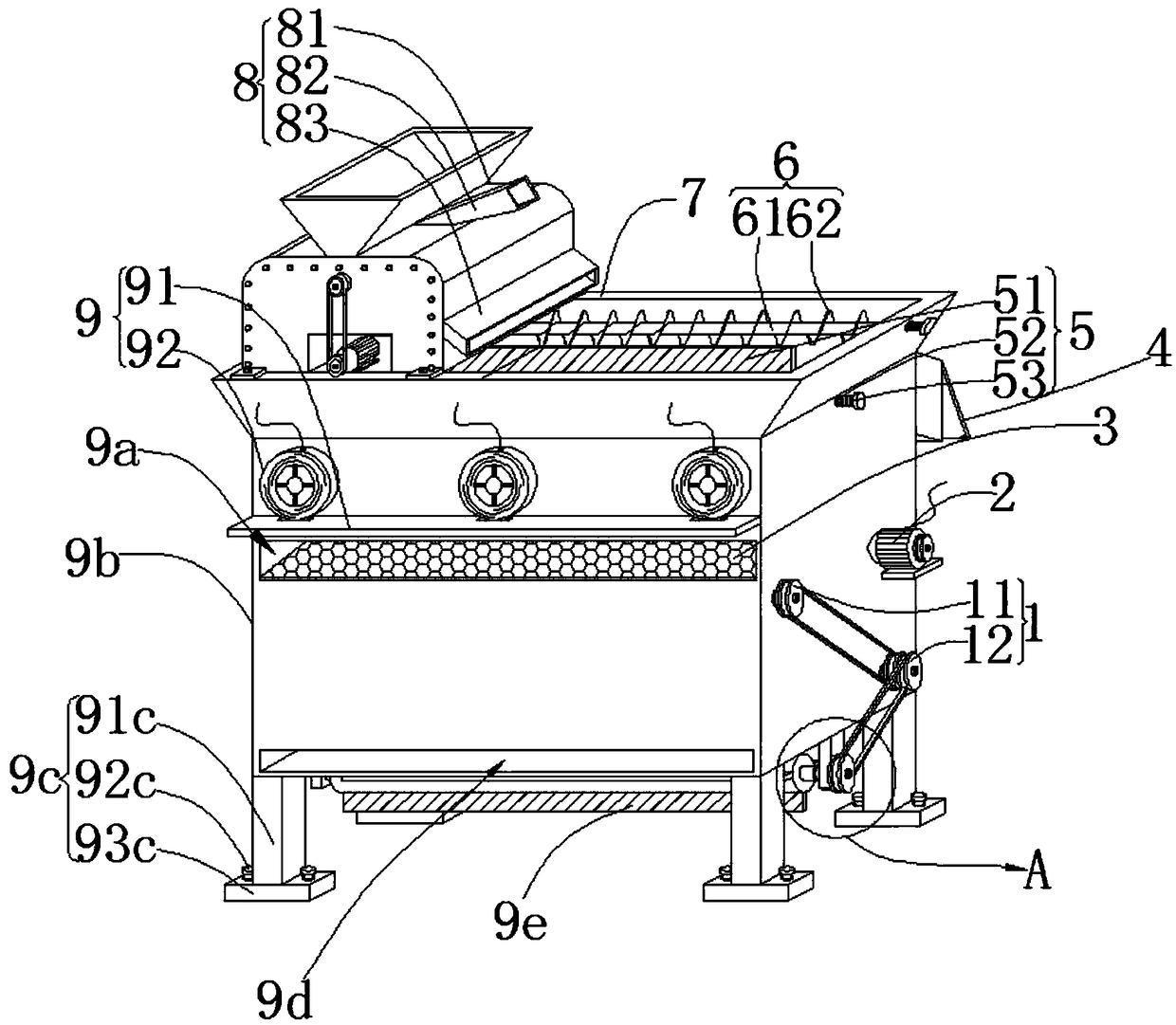

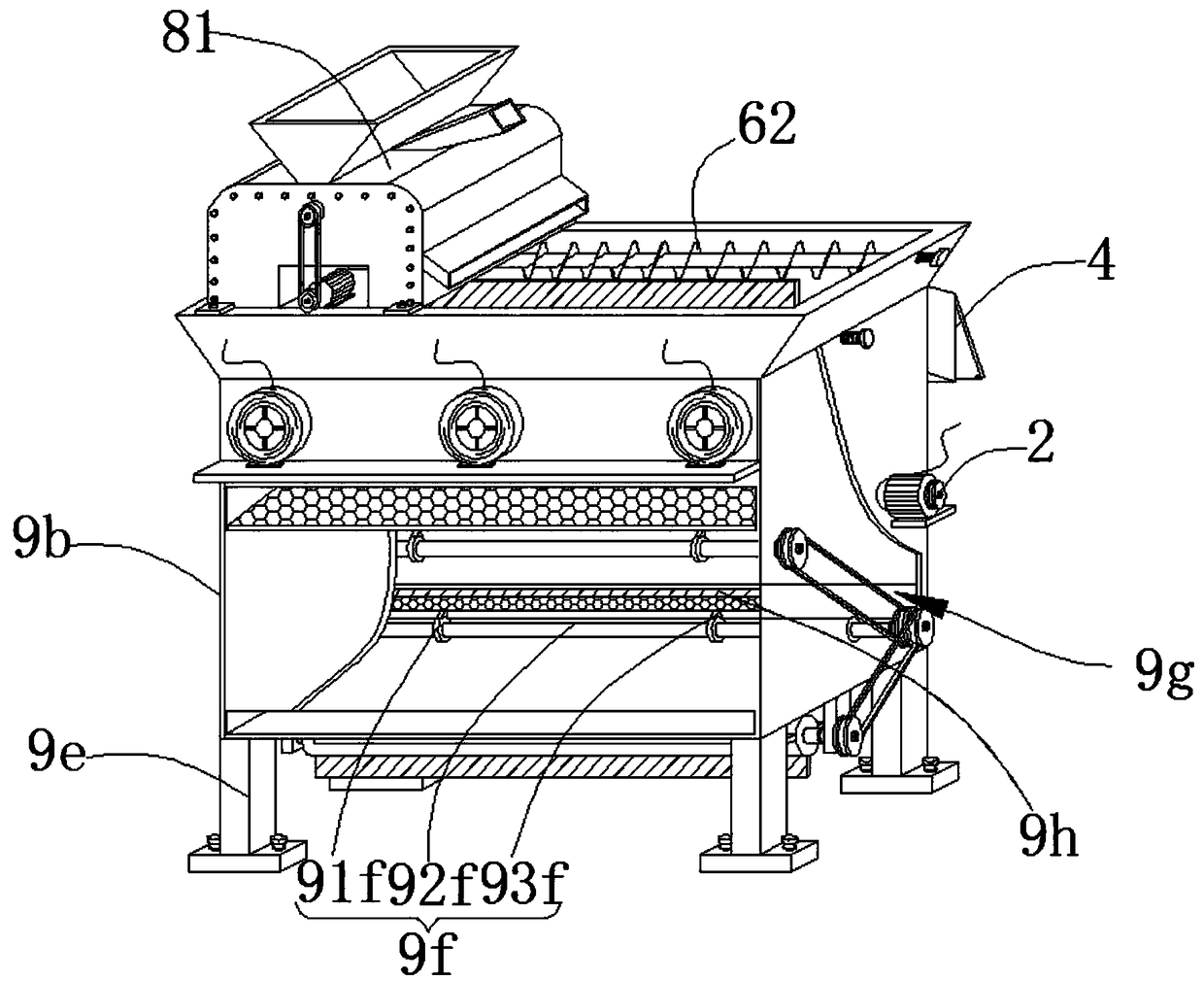

[0036] like figure 1 and figure 2 Shown, a kind of waste plastic recycling method described in the present invention, comprises the following steps:

[0037] Step 1: Sorting and sorting the recycled waste plastics with a plastic sorting machine;

[0038] Step 2, putting the plastic sorted out in step 1 into a crusher for crushing;

[0039] Step 3, put the broken plastic in step 2 into the cleaning equipment for cleaning, and wash away the impurities in the plastic;

[0040] Step 4, put the cleaned plastic in step 3 into air-drying equipment for air-drying;

[0041] Step five, put the air-dried plastic in step four into a hot-melt machine to melt the plastic;

[0042] Step six, put the plastic in step five into plastic production equipment for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com