Camera module packing method

A camera module and packaging technology, which is applied in the field of cameras, can solve problems such as irreparable, glue overflow, chip photosensitive area failure, etc., and achieve the effect of avoiding plastic overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

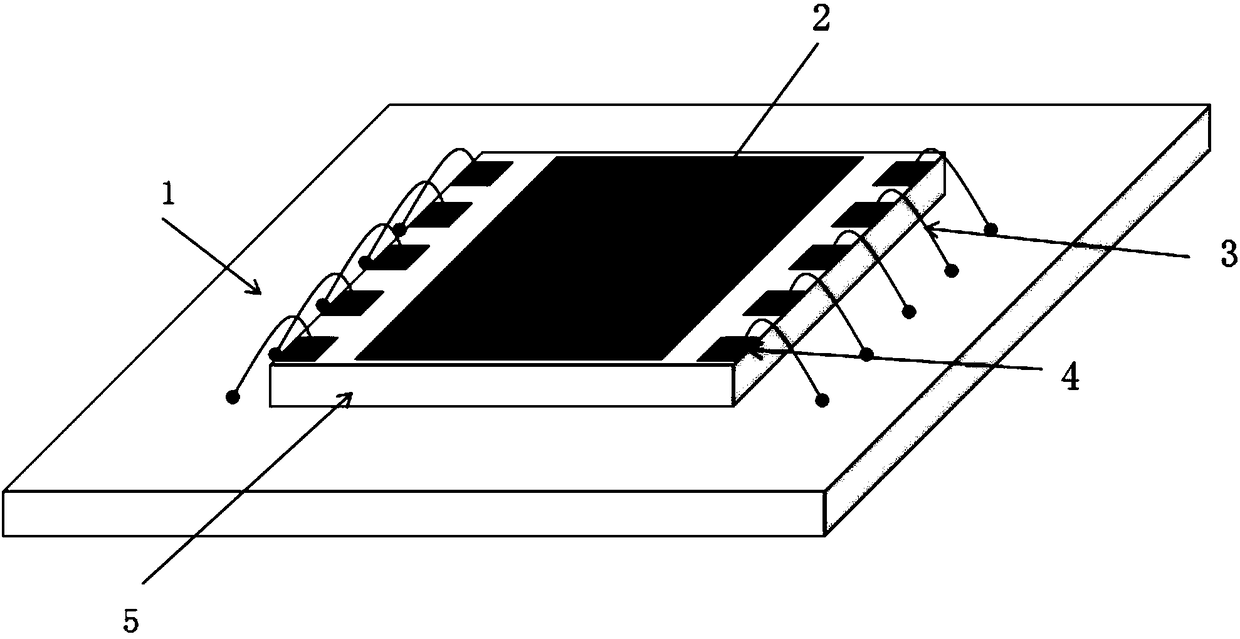

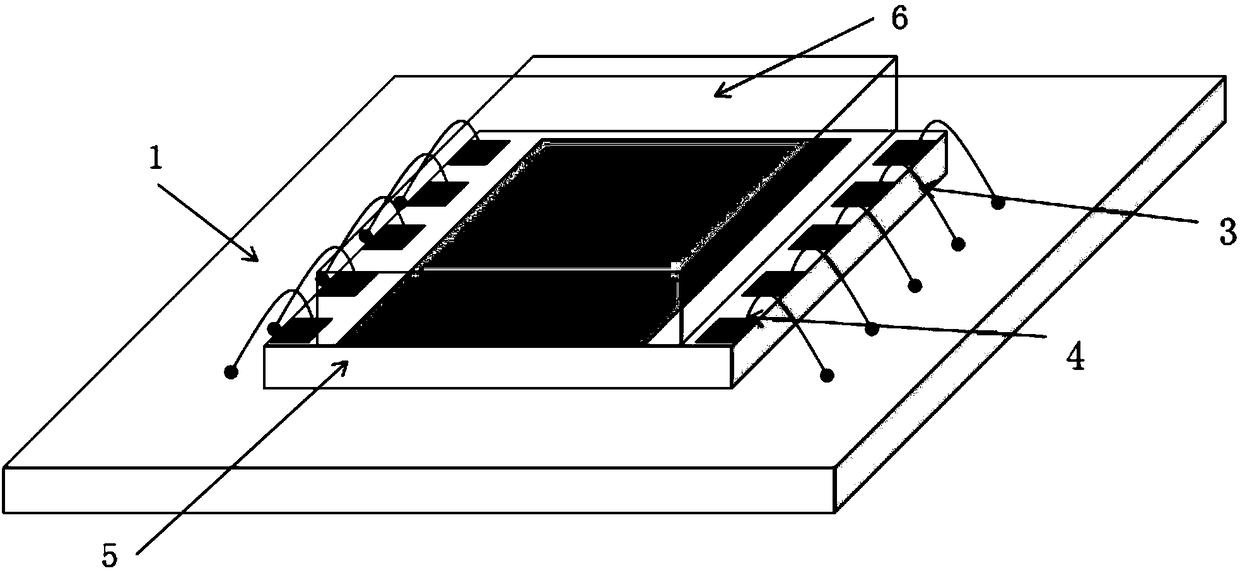

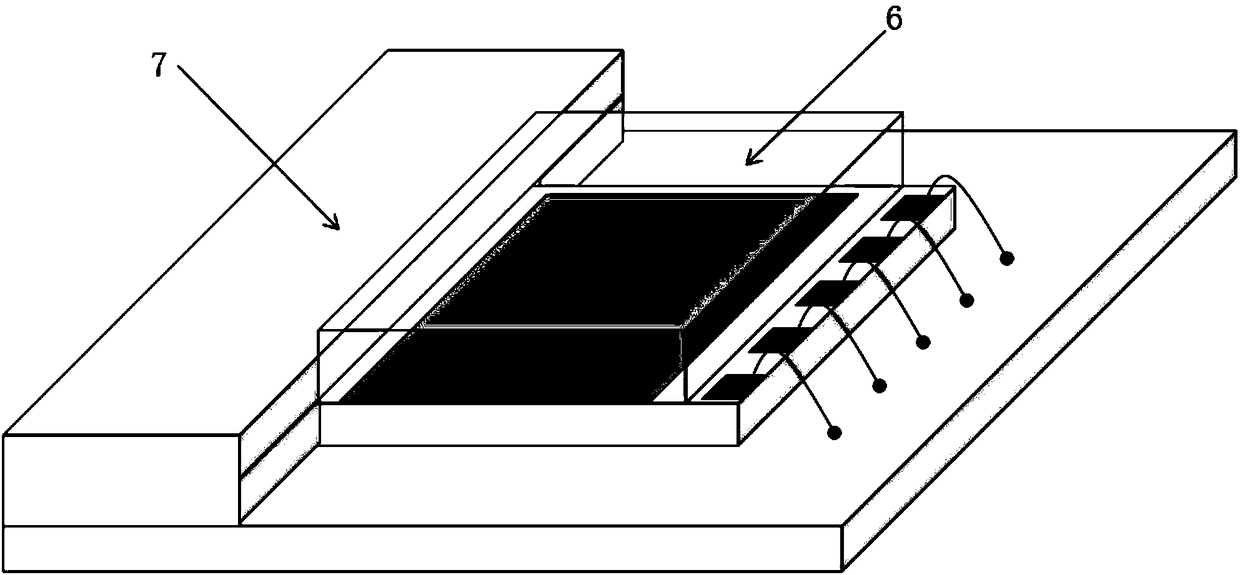

[0021] Embodiment 1: A camera module assembly method, comprising the following steps: Step 1, according to the size of the chip photosensitive area 2 of the photosensitive chip 5 and the distance between the chip photosensitive area 2 and the pad, design a filter of a suitable size 6. The size of the optical filter 6 should not be smaller than the size of the photosensitive area 2 of the chip, and at the same time, it cannot cover the pad 4 of the photosensitive chip; step 2, such as figure 2 , the filter 6 is attached on the chip photosensitive area 2 of the photosensitive chip 5, covering the chip photosensitive area 2 and not covering the photosensitive chip pad 4; Step 3, as figure 1 , the photosensitive chip 5 is bound to the circuit board 1; Step 4, as image 3 , and then place the components after step 2 in the mold for molding, and use the method of plastic sealing molding to inject injection plastic 7 on the circuit board 1 to form a plastic package, which covers th...

Embodiment 2

[0022] Embodiment two: a camera module assembly method, comprising the following steps: step one, such as figure 1 , the photosensitive chip 5 is bound to the circuit board 1; Step 2: as figure 2 According to the chip photosensitive area 2 size of the photosensitive chip 5 and the distance between the chip photosensitive area 2 and the welding pad, the filter 6 of suitable size is designed, and the size of the optical filter 6 is not less than the size of the chip photosensitive area 2, and at the same time Can not cover photosensitive chip pad 4; Step 3, attach filter 6 on chip photosensitive area 2 of photosensitive chip 5, cover chip photosensitive area 2 and do not cover photosensitive chip pad 4; Step 4, as image 3 , placed in the mold used for molding, using the method of plastic sealing molding, injection plastic 7 is injected on the circuit board 1 to form a plastic package, and the plastic package covers the non-photosensitive area of the photosensitive chip 5; S...

Embodiment 3

[0023] Embodiment 3: On the basis of Embodiment 1 or 2, the filter 6 is an ultraviolet filter or a narrow-band filter, and the others are the same.

[0024] Implementation principle: such as Figure 5 , The current camera modules all have infrared cut-off filters inside, and the infrared cut-off filters in the prior art solutions are all bonded on the lens bracket by glue. However, the present invention directly attaches the infrared cut-off filter to the surface of the photosensitive area 2 of the chip, and then performs MOC injection molding, thereby preventing the injection plastic 7 from overflowing into the photosensitive area 2 of the chip, such as Figure 4 .

[0025] Compared with the prior art, the above embodiment has the beneficial effects that: the photosensitive area of the chip is protected by the optical filter, and the injection molding plastic will not overflow to the photosensitive area of the chip, avoiding the problem of plastic overflow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com