Efficient intensive-type automated logistics sorting storage warehouse system

An intensive, logistics technology, applied in the field of warehousing and access, can solve the problems of low efficiency in sorting and distribution, and achieve the effect of small footprint, reduced error rate, and reasonable layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

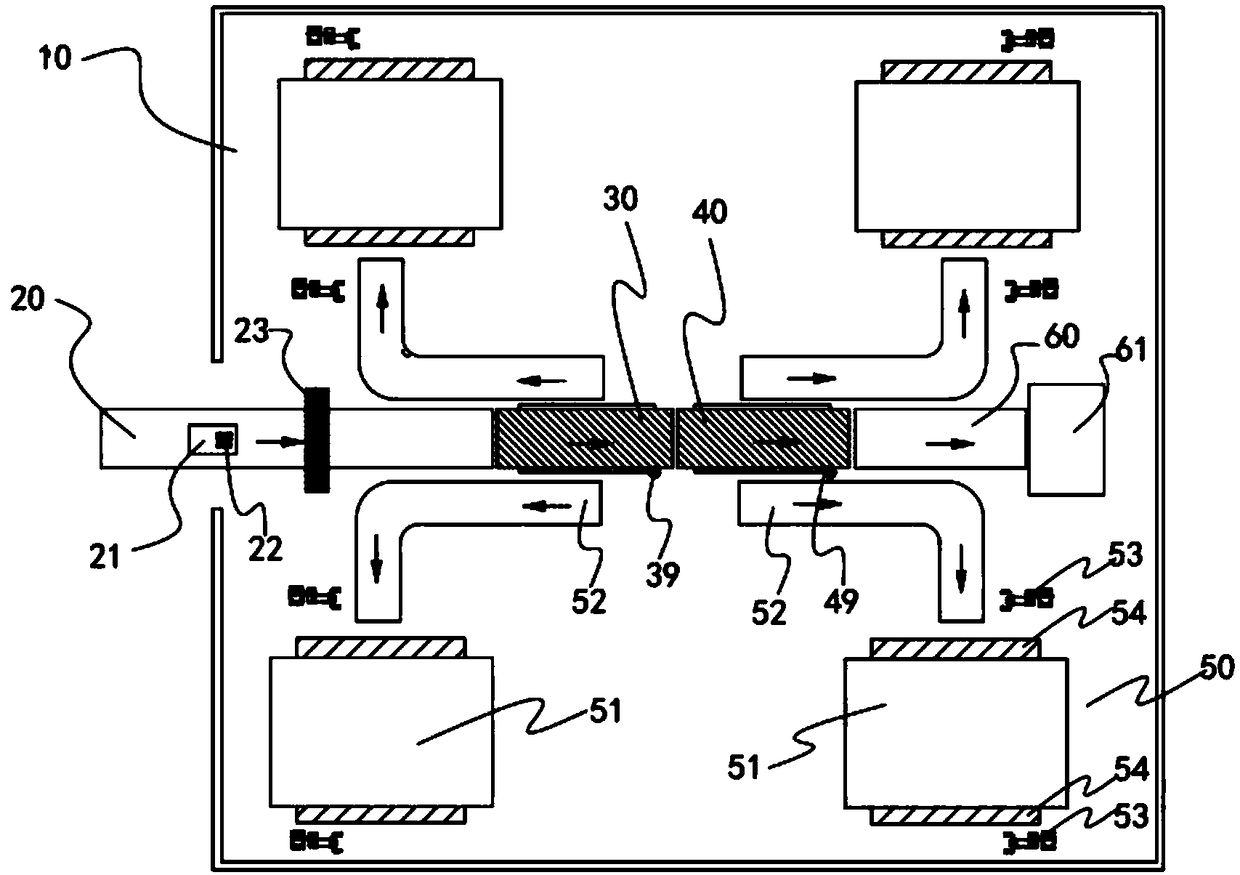

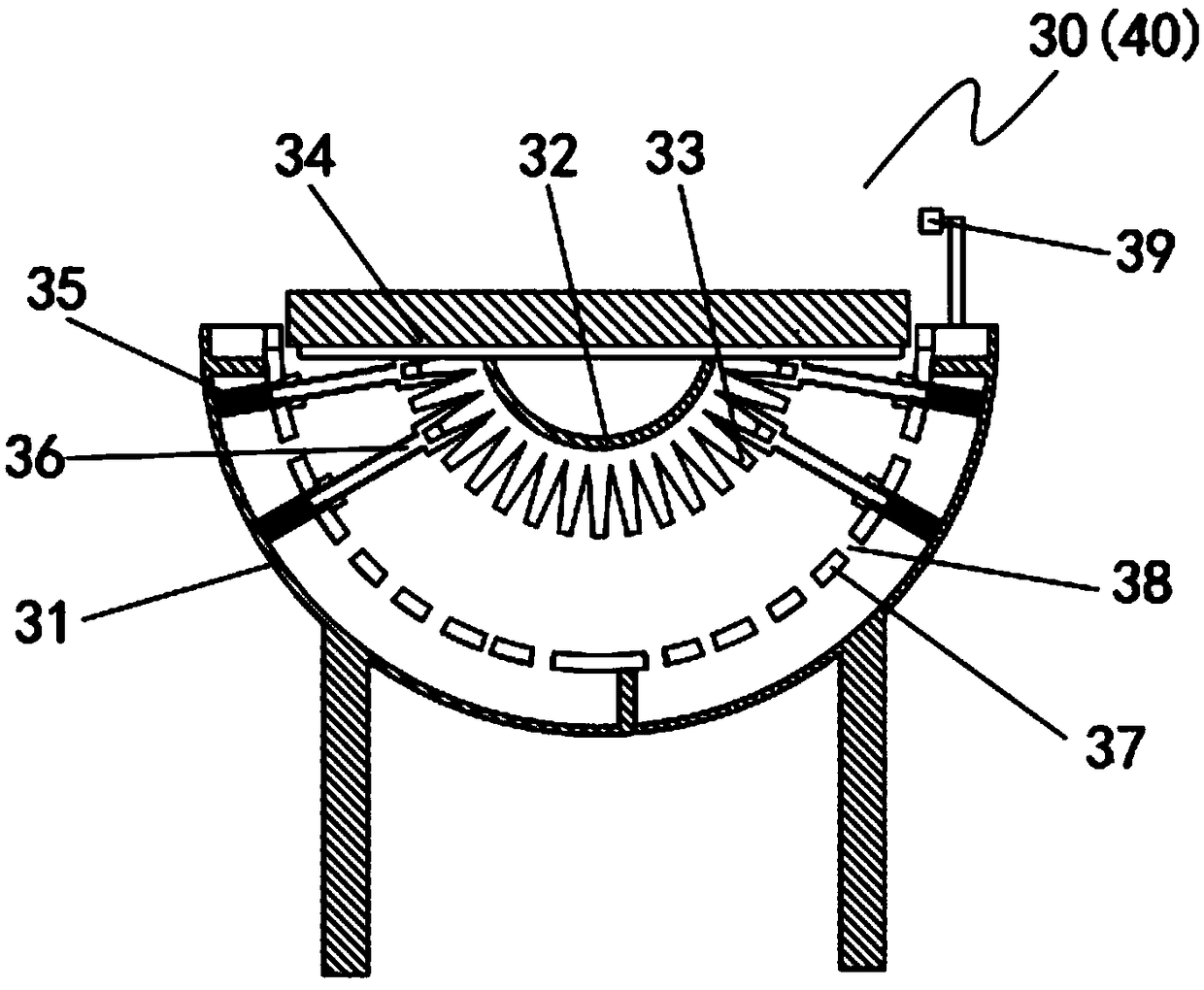

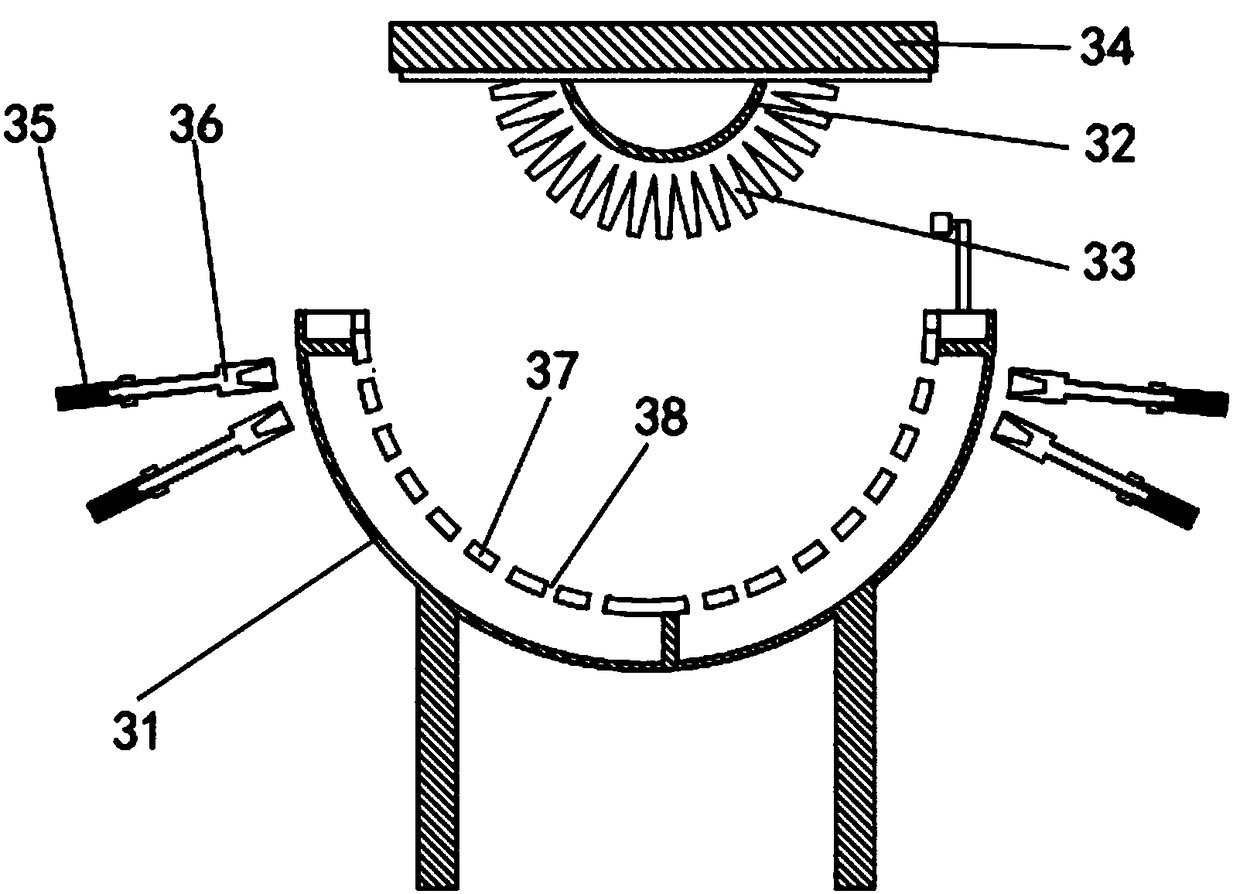

[0036] Such as Figure 1-2As shown, the embodiment of the present invention provides a high-efficiency and intensive automatic logistics sorting and storage warehouse system, including a warehouse 10 and a front-end conveyor belt 20 sequentially arranged in the warehouse 10, a first turning and sorting mechanism 30, a second turning and sorting mechanism. Picking structure 40 and tail end conveyor belt 60; wherein, above the front end conveyor belt 20, a code scanner 23 for identifying the corresponding two-dimensional code 22 on the surface of the goods 21 is installed; the first flipping sorting mechanism 30, the second flipping sorting structure Storage devices 50 are arranged on both sides of 40 respectively. The storage device 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com