Leveling device of wall plaster based on minusing

A technology of subtraction and decoration, applied in the direction of construction and building structure, can solve problems such as deformation and affect the accuracy of construction, and achieve the effect of increasing the thickness of the guide rail and improving the accuracy of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

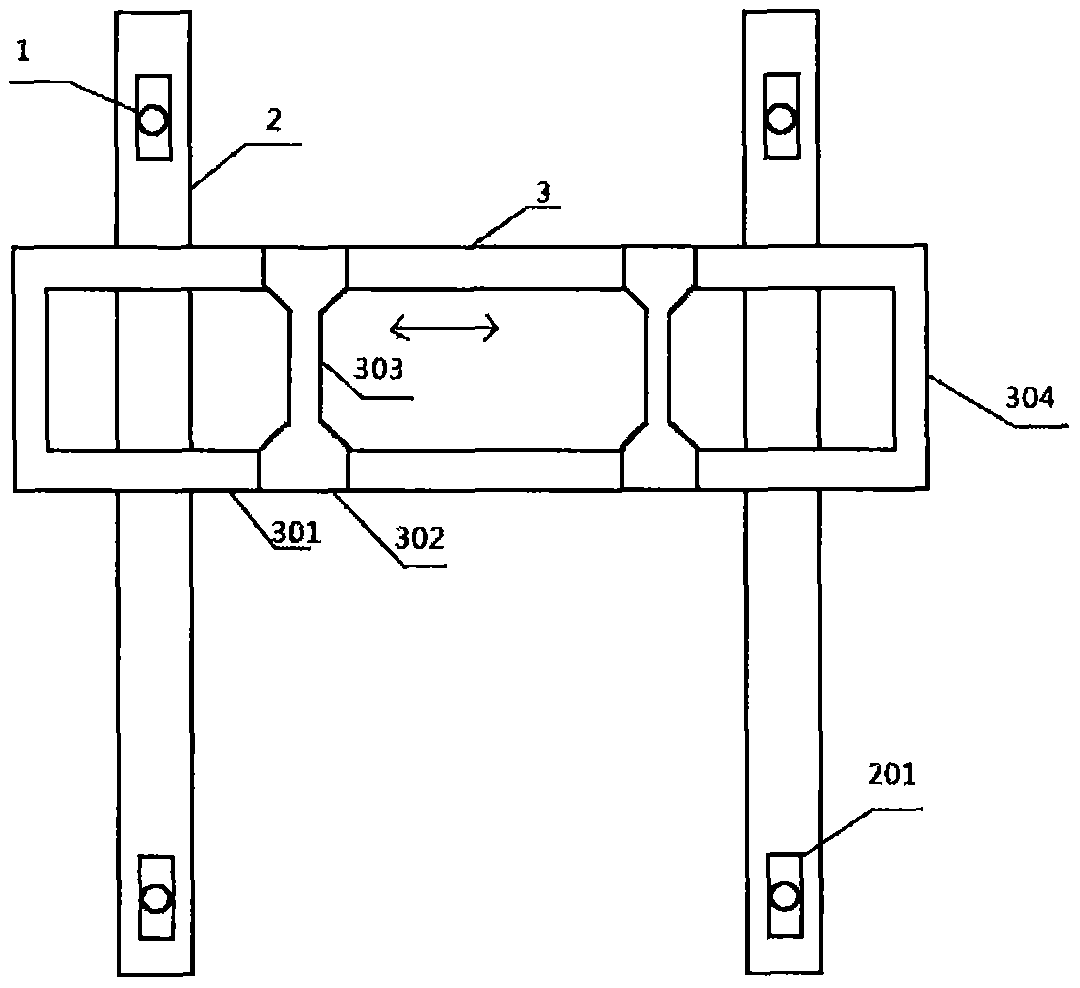

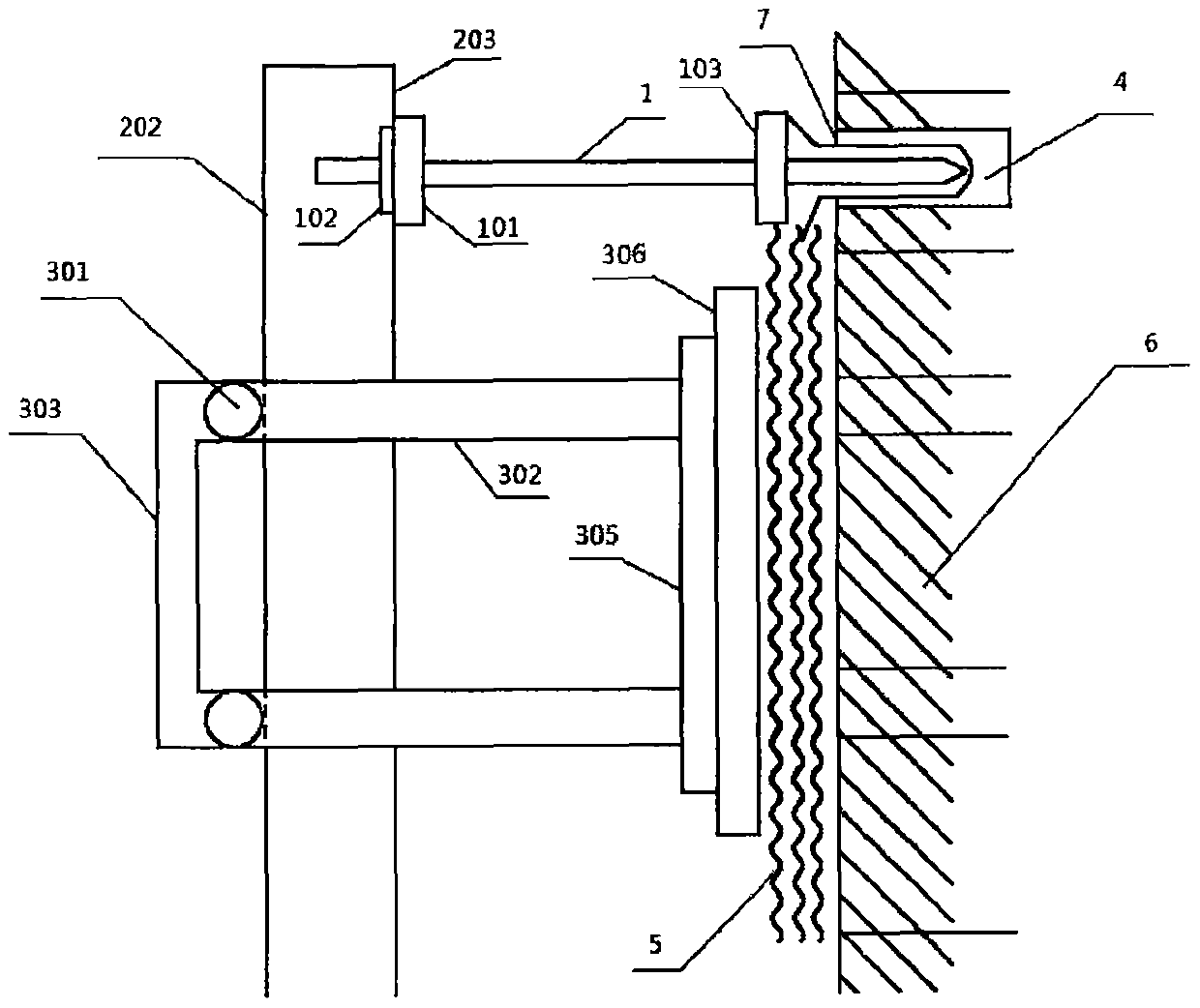

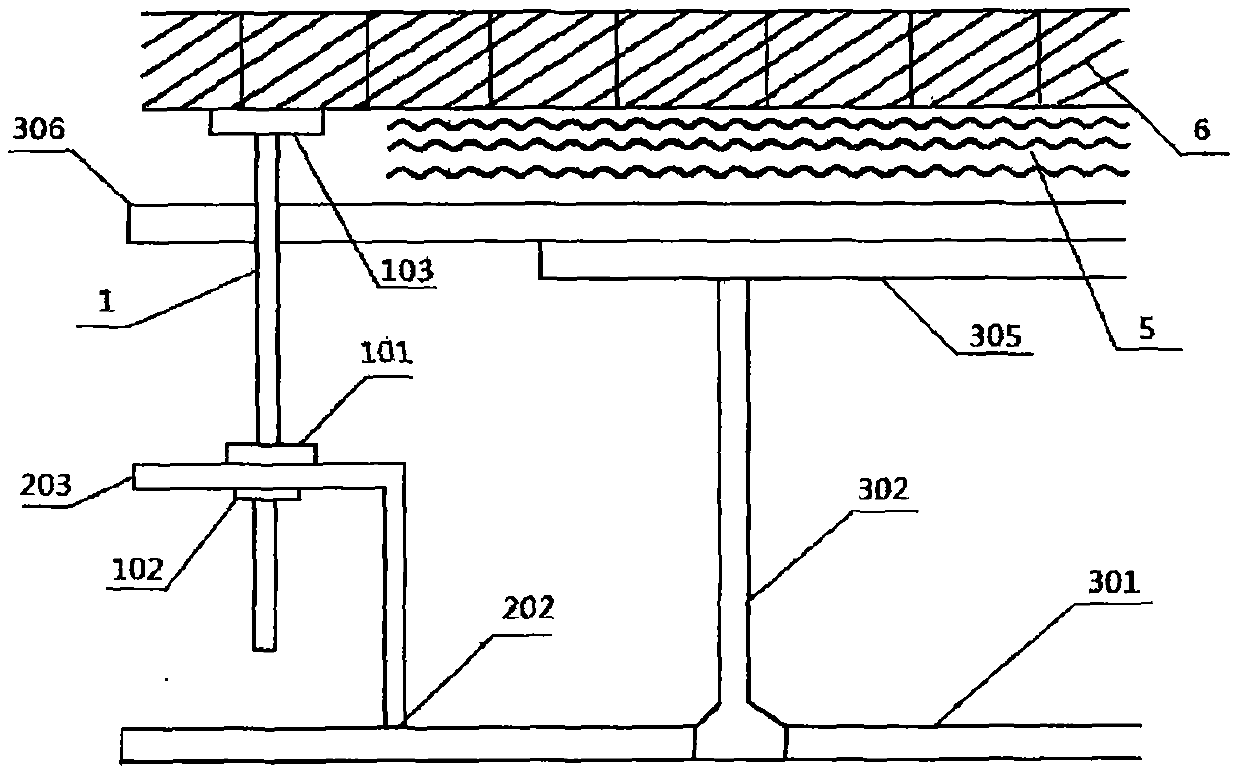

[0030] Attached below figure 1 , 2 , 3 and examples are further elaborated: the device for leveling the wall finish by the subtraction method is composed of a positioning device, a guide, and a leveling device 3. The guiding device is fixed on the body of wall 6 through the positioning device, and the leveling device 3 uses the guiding device as a track to slide and level the whitewash layer 5 .

[0031] The positioning device consists of a plurality of threaded rods 1 . One end of each threaded rod 1 is pointed, and is fixed on the wall body 6 through the hole 4 of the soft expansion tube 7 made and plugged in advance. The threaded rod 1 exposed on the wall 6 is provided with a positioning nut 101 , a clamping member 102 and a limiting member 103 . The length of the threaded rod 1 inside the wall body 6 is controlled by the limit piece 103 . On the wall body of the same plane, the positioning nut 101 of the threaded rod 1 is on the same vertical plane.

[0032] The guidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com