Travelling cable for low-rise building elevator

A technology of accompanying cables and elevators, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of power-off stop function, consume more electric energy, increase the weight of accompanying cables, etc., and achieve the effect of large design freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

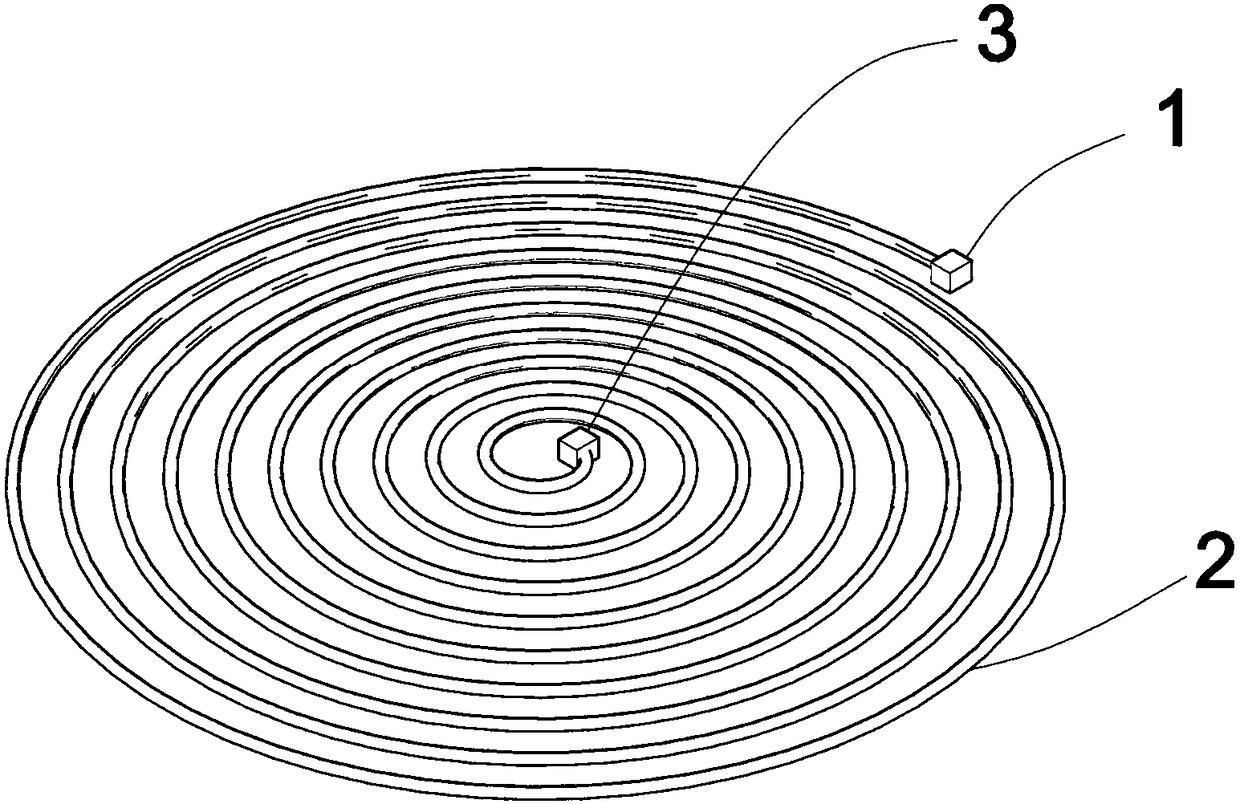

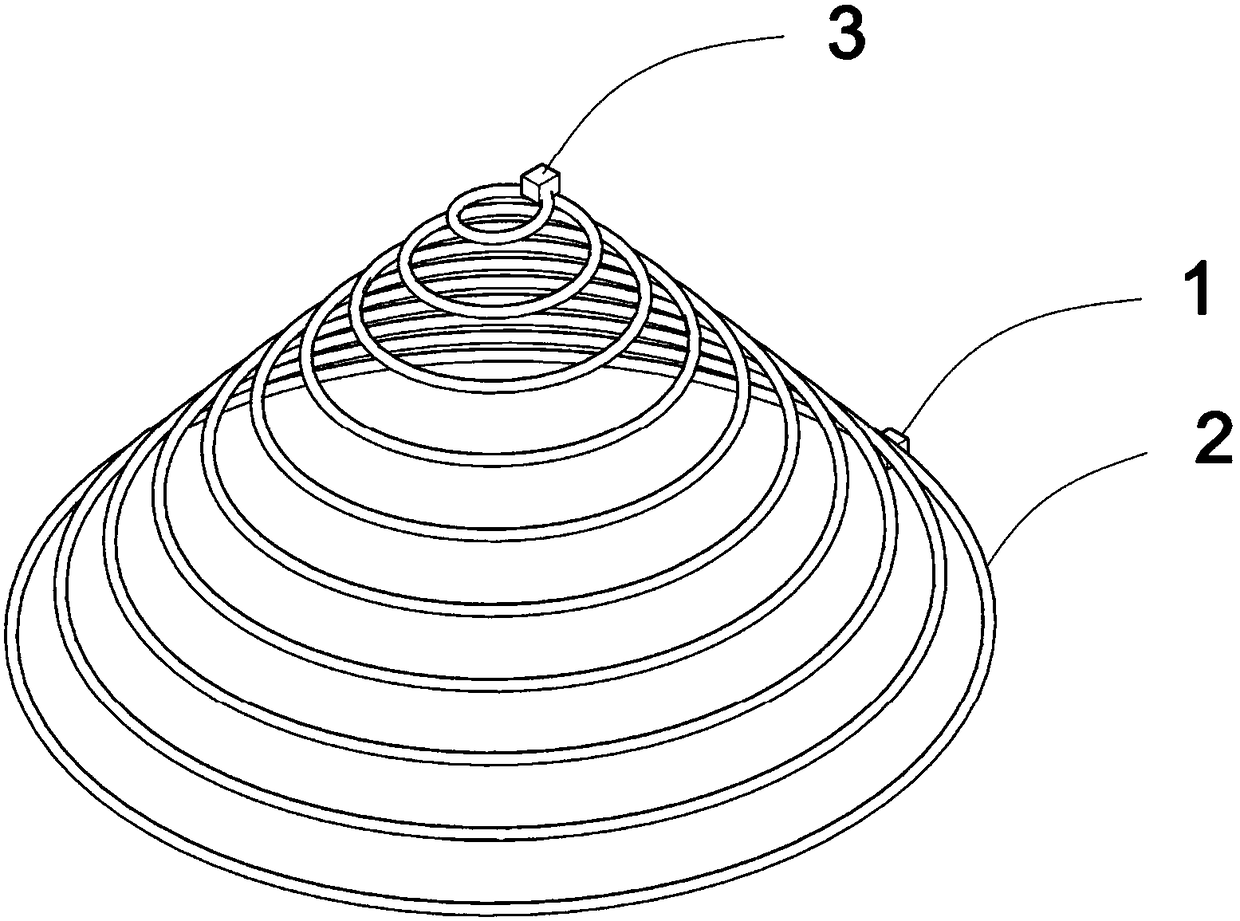

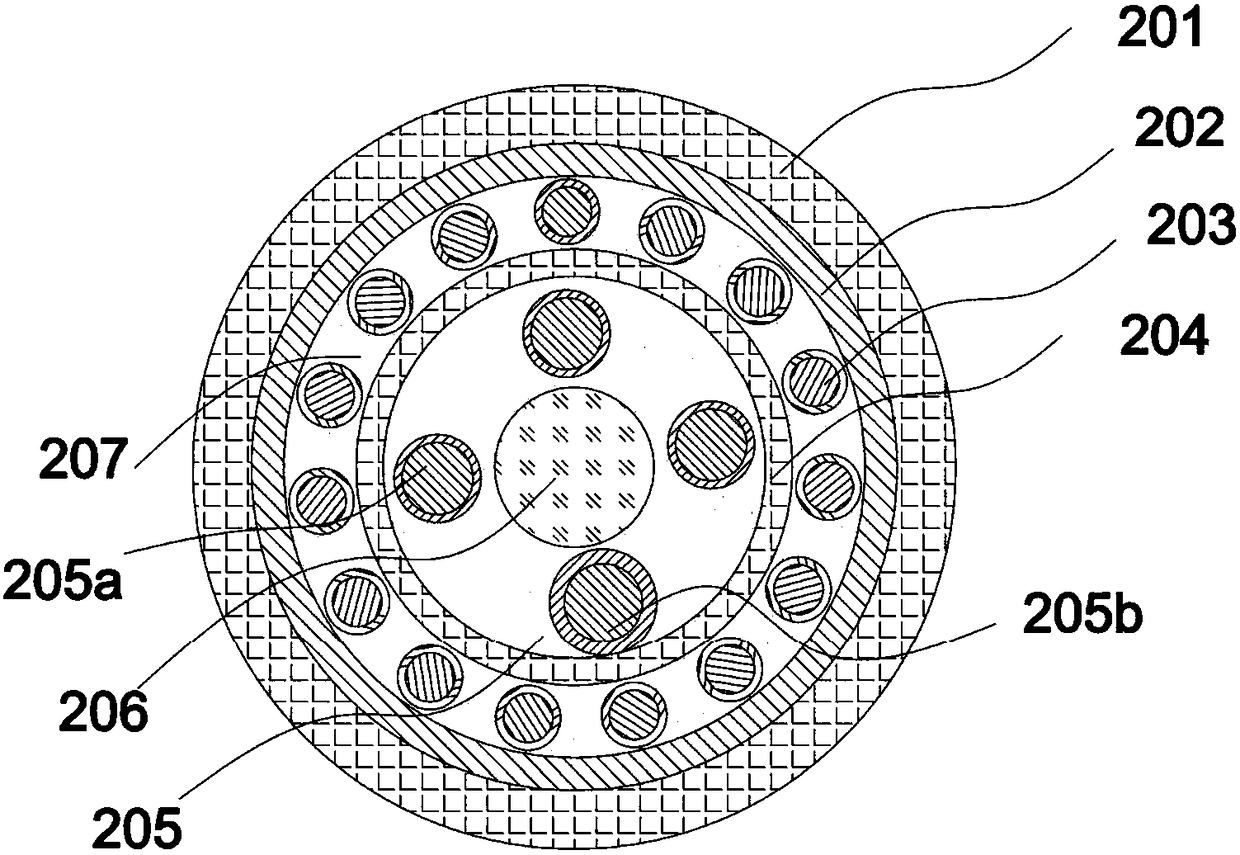

[0030] Such as figure 1 , 3 As shown, an accompanying cable for a low-rise building elevator includes: a first input connector 1, a first output connector 3 and a main cable 2, and the first input connector 1 and the first output connector 3 are arranged on the main cable 2 At both ends, the cross-section of the main cable 2 is circular or flat, and the main cable 2 includes a sheath layer 201, a braided layer 202, a control line layer 203, a shielding layer 204, a main line layer 205, and a steel wire 206 from outside to inside. It also includes a filler 207; the main line layer includes a power line 205a and a communication line 205b;

[0031] The shape of the main cable 2 is an Archimedes spiral, and the distance between each cable arm is greater than the diameter of the main cable 2;

[0032] Such as figure 2 , when the elevator is at the lowest floor, the main cable 2 is flatly laid on the ground directly below the elevator car in a disc shape; when the elevator rises...

Embodiment 2

[0038] The accompanying cable is extended through the adapter 7 and the extension cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com