System and method for detecting air gap of wind power generator in real time

A wind turbine, real-time detection technology, applied in wind power generation, electrical components, measurement devices, etc., can solve the problem of not being an air gap, not taking into account the simultaneous measurement of multiple positions in the axial direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

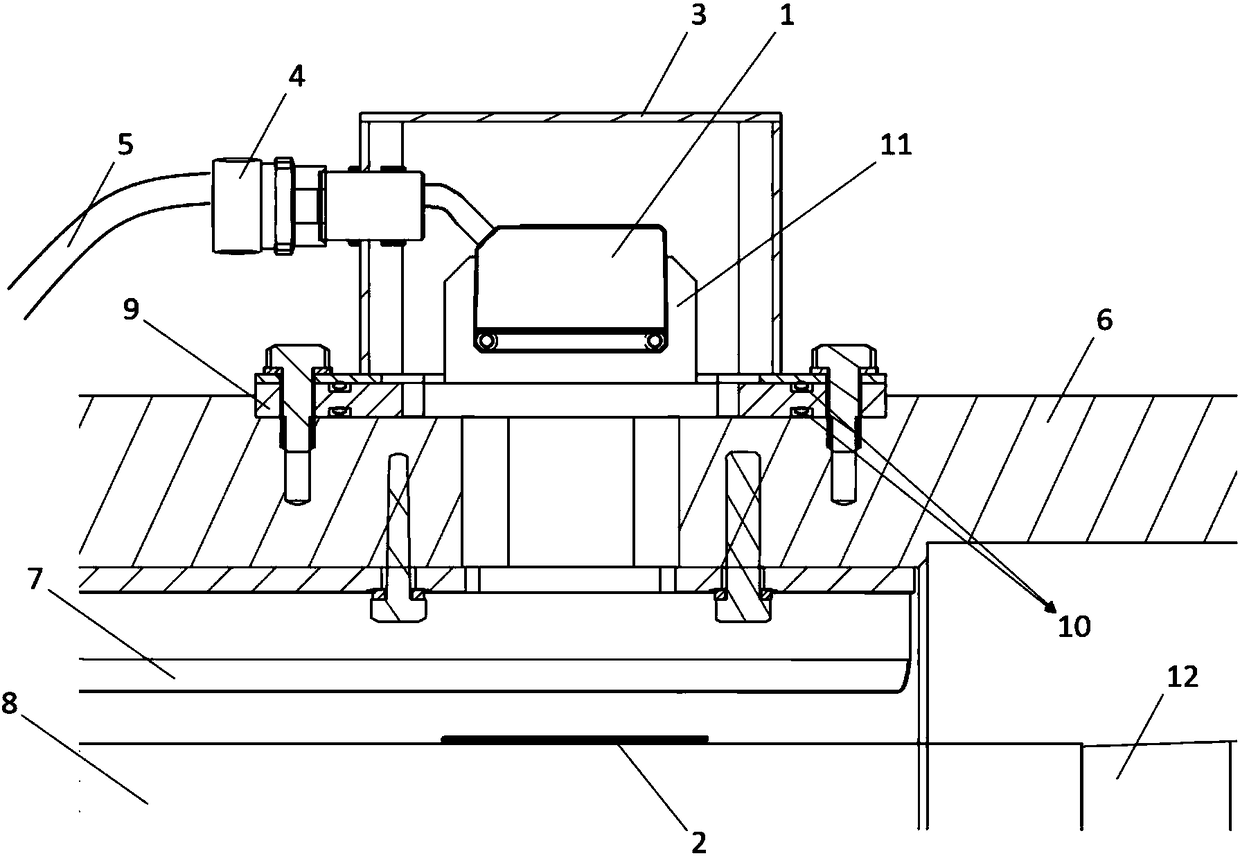

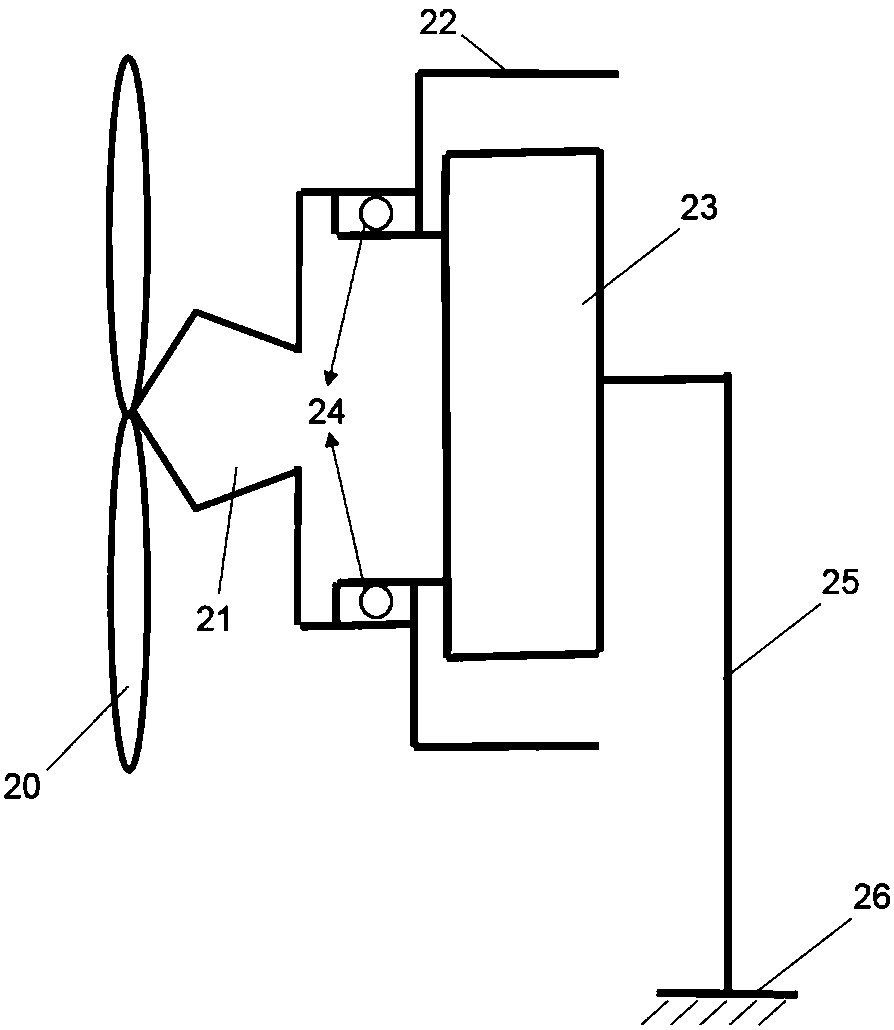

[0032] Such as figure 1 , shown in 2, a wind-driven generator air gap real-time detection system, including a wind-driven generator, a laser sensor 1, a capacitance sensor 2, the distance between the stator silicon steel sheet 8 of the wind-driven generator and the rotor magnetic steel 7 is the wind-driven generator The air gap, at least one laser sensor 1 is fixedly connected on the rotor shell 6 through the mounting bracket 11; at least one capacitive sensor 2 is pasted on the surface of the stator silicon steel sheet 8, and the laser beam emitted by the laser sensor 1 can be irradiated on the surface of the capacitive sensor 2, A set of sensor measuring devices is formed for measuring the air gap of the wind turbine.

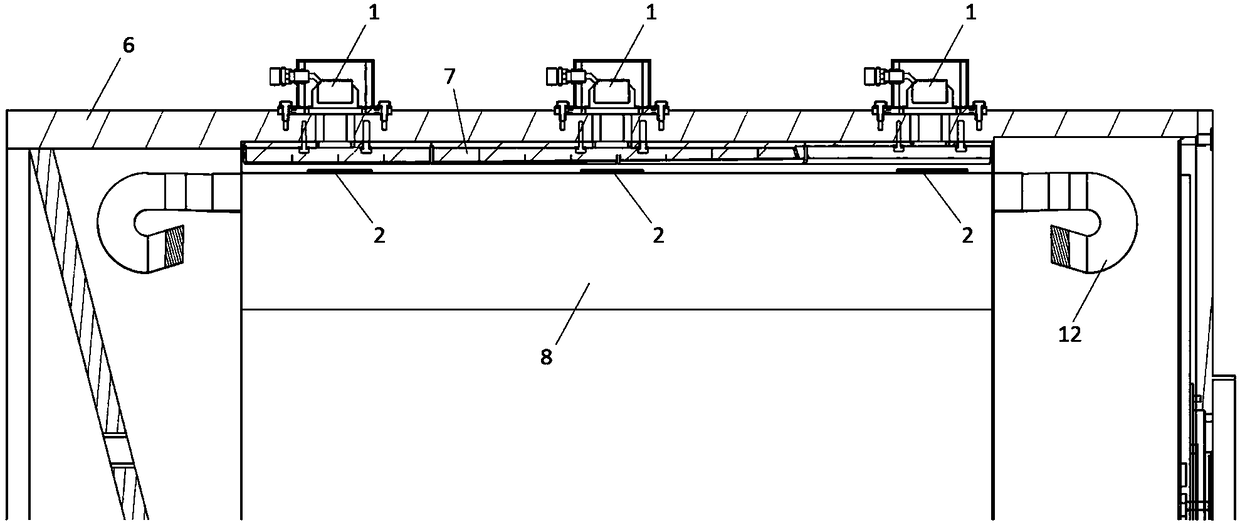

[0033] Such as figure 2 As shown, three sets of sensor measuring devices are arranged axially in the wind turbine for real-time an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com