Fixing device for drilling hole in plate

A fixing device and plate technology, applied in the field of workpiece processing, can solve the problems of labor-intensive, defective parts processing, inability to meet hole spacing requirements, etc., and achieve the effect of wide application range and large adjustment range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

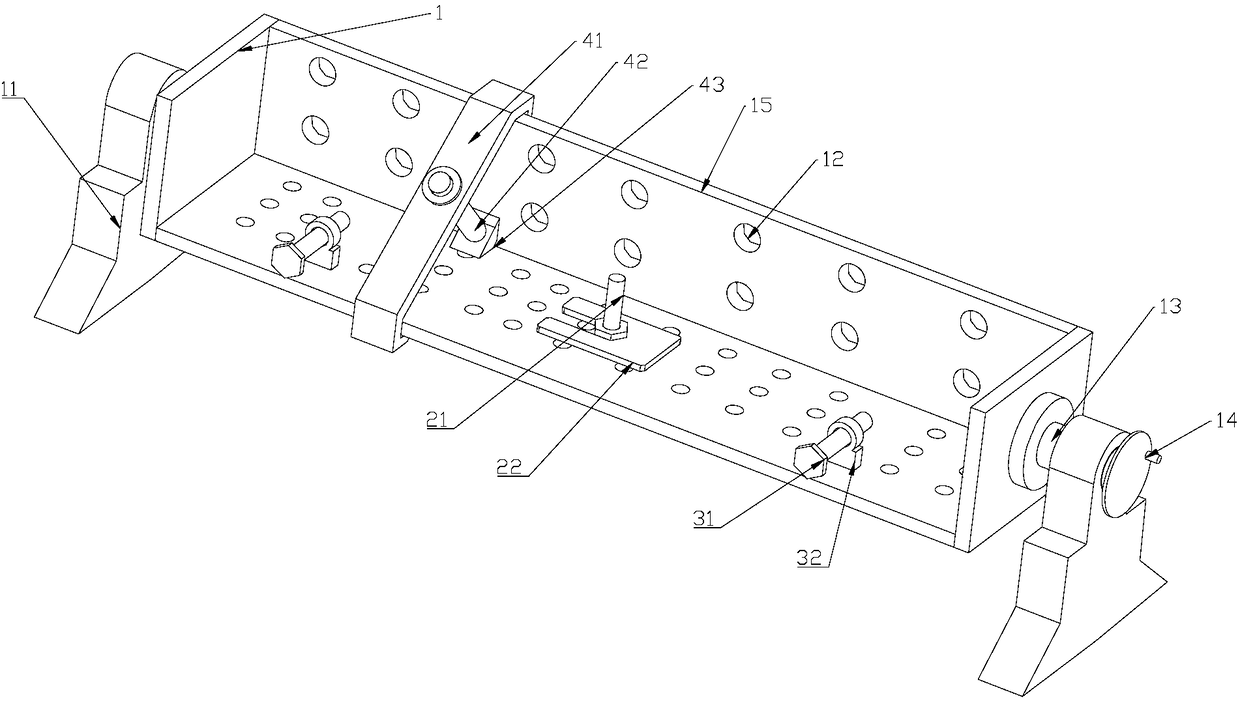

[0036] like figure 1 , the first fixture includes a fixing bolt 21 and a pressure plate 22, one end of the fixing bolt 21 is vertically fixed to the positioning plate 15, the pressure plate 22 is set as a U-shaped plate, and the pressure plate 22 sleeved on the fixing bolt 21 is passed through a nut fixed.

[0037] The first fixture utilizes the pressing plate 22 to compress the parallel side of the plate and its pressing plate. The pressing plate 22 can fix the plates on both sides of the fixing bolt 21 at the same time. The fixing range of the pressing plate 22 is large, and one part can realize the fixing of multiple plates. By clamping the face of the sheet.

Embodiment 2

[0039] like figure 1 , the first fixture includes a compression bolt 31 and a threaded sleeve 32, the threaded sleeve 32 is vertically fixed to one of the positioning plates 15, and the compression bolt 31 passes through the threaded hole of the threaded sleeve 32 and is threadedly connected with it.

[0040] The first clamp utilizes the compression bolt 31 to compress the plate and its vertical side. The first clamp can clamp the veneer, and the compression bolt 31 is fixed through the point on the opposite surface.

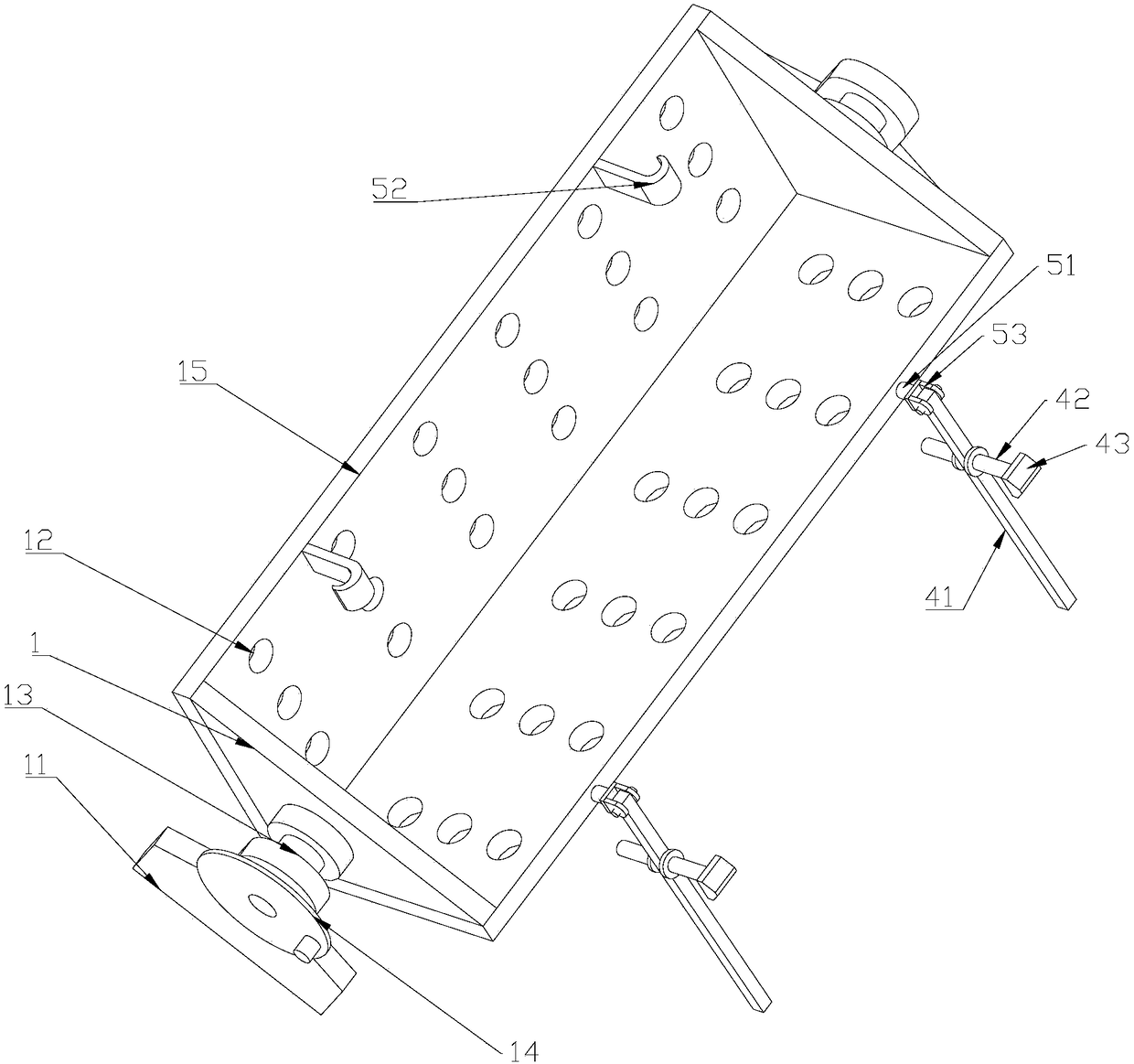

[0041] The second fixture includes a positioning block 43, a positioning shaft 42 and a positioning frame 41, the positioning frame 41 is movably connected with two positioning plates 15, and a connecting hole is arranged on the positioning plate 15, and the positioning shaft passing through the connecting hole One end of 42 is movably connected with the positioning frame 41 through a nut, and the other end of the positioning shaft 42 is fixed with the position...

Embodiment 3

[0044] like figure 1 The positioning frame 41 is configured as a connecting plate with bent portions at both ends, the connecting plate is arranged between the two positioning plates 15, and the two bent portions are respectively against the backs of the two positioning plates 15.

[0045] The positioning frame 41 slides along the length direction of the positioning plate 15 for disassembly, installation and positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com