Foldable and curved space truss capture mechanism

A space truss, bending technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of poor controllability, easy knotting or entanglement of rope nets, unsuitable for capturing large targets, etc., to achieve high capture reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

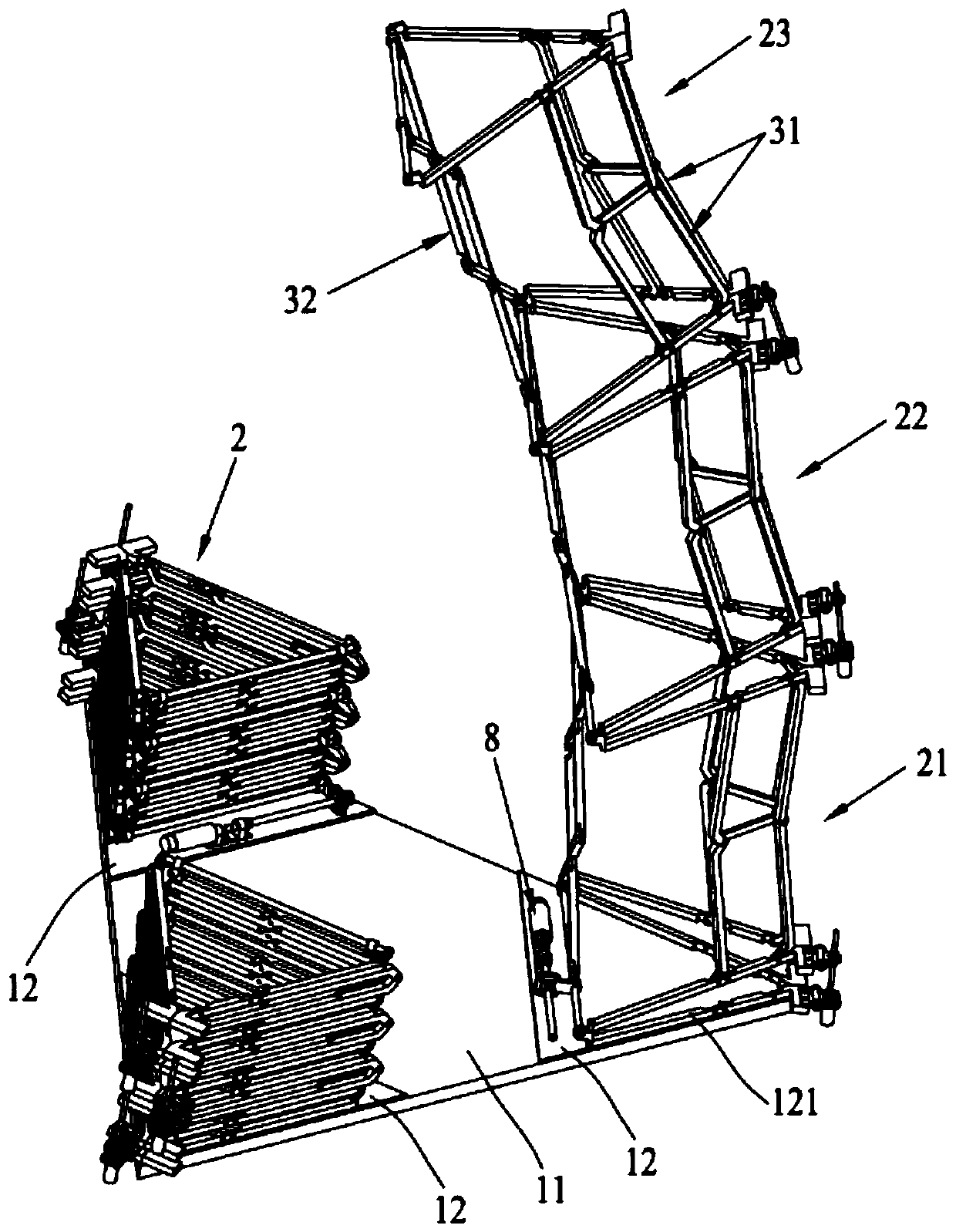

[0036] Such as figure 1 As shown, the base in Embodiment 1 includes an assembly base 11 and three mechanism bases 12 installed on the assembly base 11 , and the mechanism base 12 has a base triangular frame 121 . A foldable and bendable truss mechanism 2 and a foldable driving device 8 are installed on each mechanism base 12 ; wherein, the foldable driving device 8 is used to drive the unfolding and folding of the truss mechanism 2 . figure 1 Among them, one truss mechanism 2 is in a fully unfolded and bent state, and the other two truss mechanisms 2 are in a folded state.

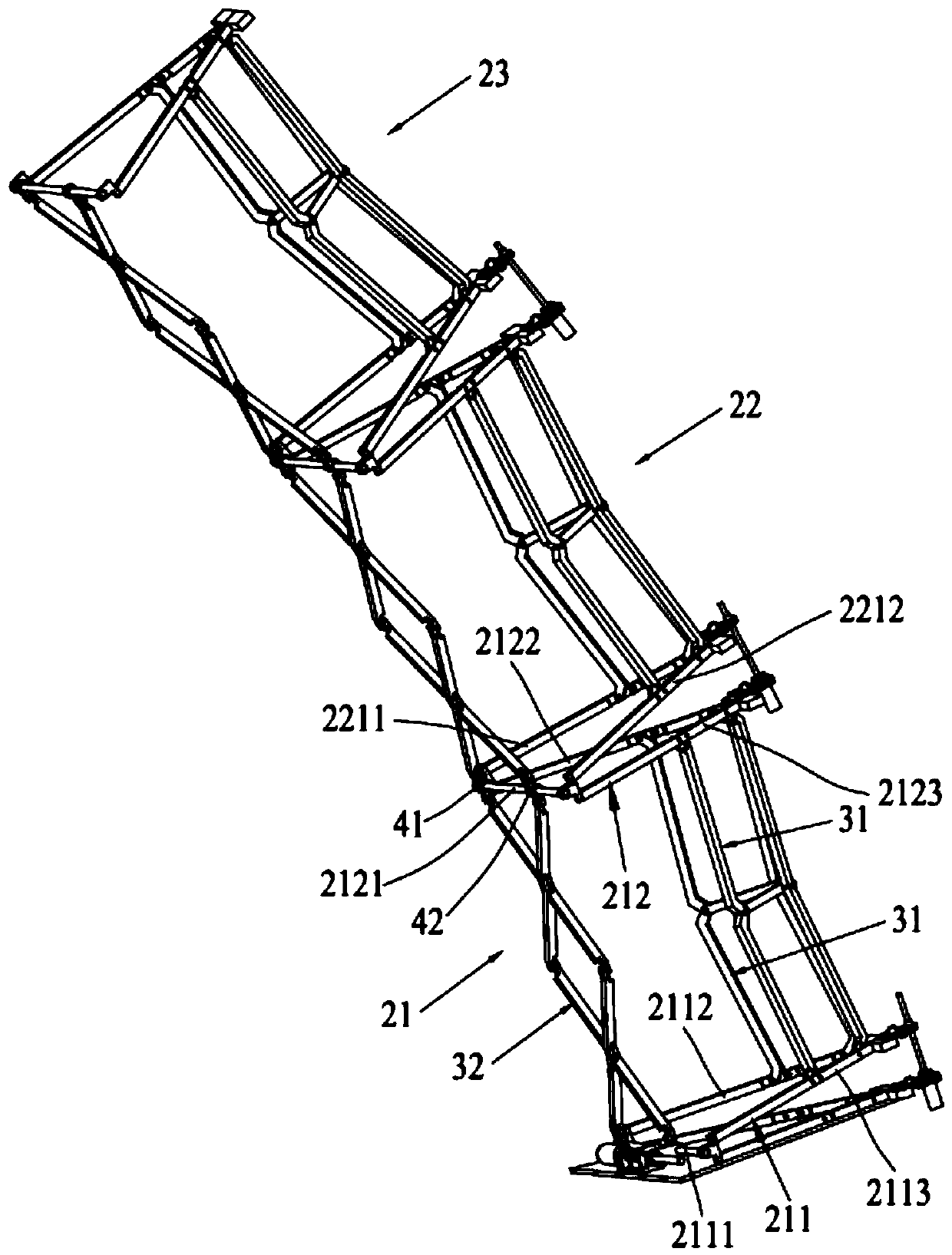

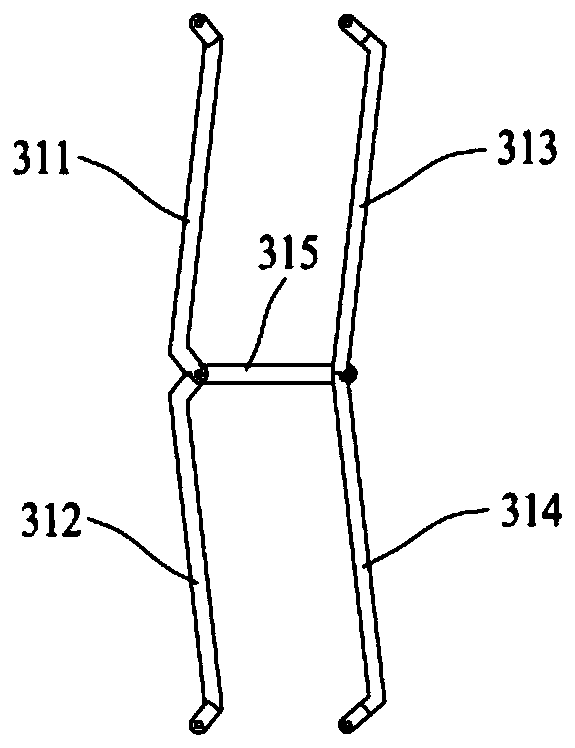

[0037] Each truss mechanism 2 includes sequentially connected N (N≥2) folding units, for example, including sequentially connected first folding unit 21, second folding unit 22 and third folding unit 23; wherein, each A folding unit includes two triangular frames arranged parallel to each other, and the triangular frame includes a roller shaft and two sides; the two parallel sides of the same folding unit...

Embodiment 2

[0050] The difference between Embodiment 2 and Embodiment 1 lies in the difference between the middle bending driving device and the bottom bending driving device, so only the differences between Embodiment 2 and Embodiment 1 will be described below.

[0051] In Embodiment 2, a rotating motor is provided on the side of the top of the n-1th folding unit, and the rotating motor is connected to the side of the bottom of the nth folding unit through a transmission mechanism, and the rotating motor and the transmission mechanism It constitutes an intermediate bending driving device; the transmission mechanism includes an active component and a driven component, one end of the active component is fixedly connected to the power output shaft of the rotating electrical machine, one end of the driven component is hinged to the other end of the active component, and the other end of the driven component Hinged with the side at the bottom of the nth folding unit.

[0052] Specifically, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com