Anti-sticking storage device for diced particles of extruder

A storage device and anti-sticking technology, applied in the field of storage devices, can solve the problems affecting the use effect of color masterbatch, reduce the quality of color masterbatch, bridging, etc., and achieve the effects of preventing adhesion, good wear resistance and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

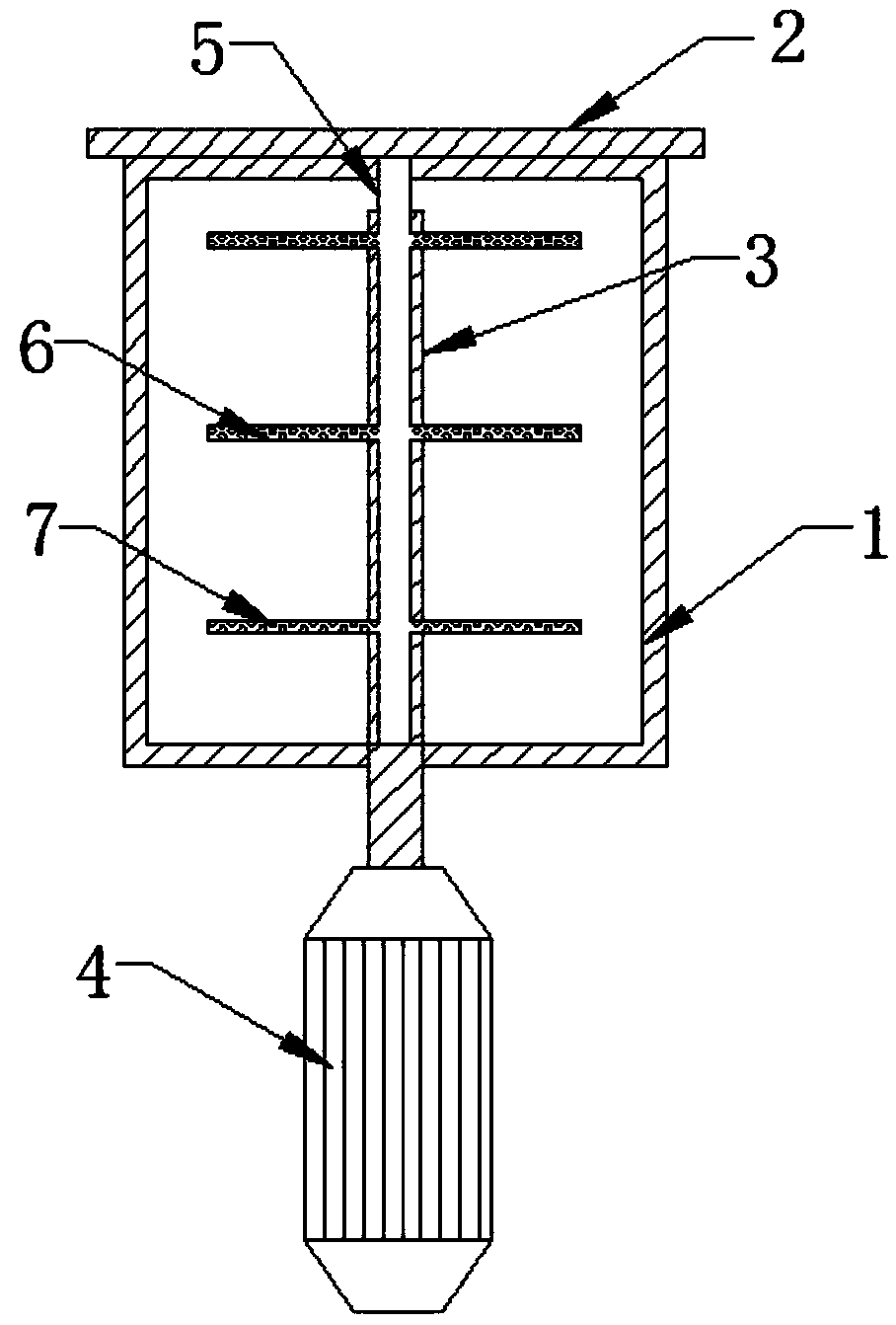

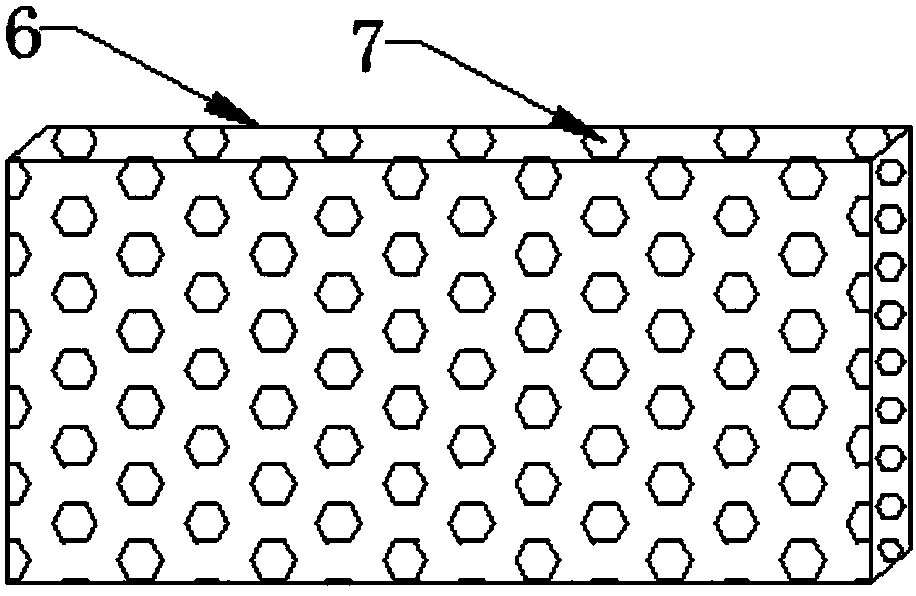

[0017] like Figure 1-2 As shown, the present invention provides a kind of anti-stick storage device for extruder pelletizing, comprising a storage bucket 1, the top of the storage bucket 1 is provided with a bucket cover 2, the inside of the storage bucket 1 is provided with a stirring shaft 3, the stirring shaft 3 Through the bottom of the storage bucket 1 and extending to the outside of the storage bucket 1, one end of the stirring shaft 3 is connected with a motor 4, and the motor 4 is located at the bottom of the storage bucket 1, and the inside of the stirring shaft 3 is provided with a hollow cylinder 5, which can be placed on the hollow cylinder 5 The interior is filled with a slip agent, which can reduce viscosity and friction, and can lubricate both inside and outside, which can reduce the wear between the masterbatch particles and improve the wetting effect of the masterbatch. The hollow cylinder 5 is provided with a hollow Stirring blade 6, and hollow stirring blad...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap