Multifunctional PBO knitted casing pipe

A multi-functional, casing technology, applied in pipeline protection, pipeline anti-corrosion/anti-rust protection, pipeline damage/wear prevention, etc., can solve the problems of poor overall effect, single function, simple structure, etc. The outer surface is wear-resistant and the overall function is perfect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

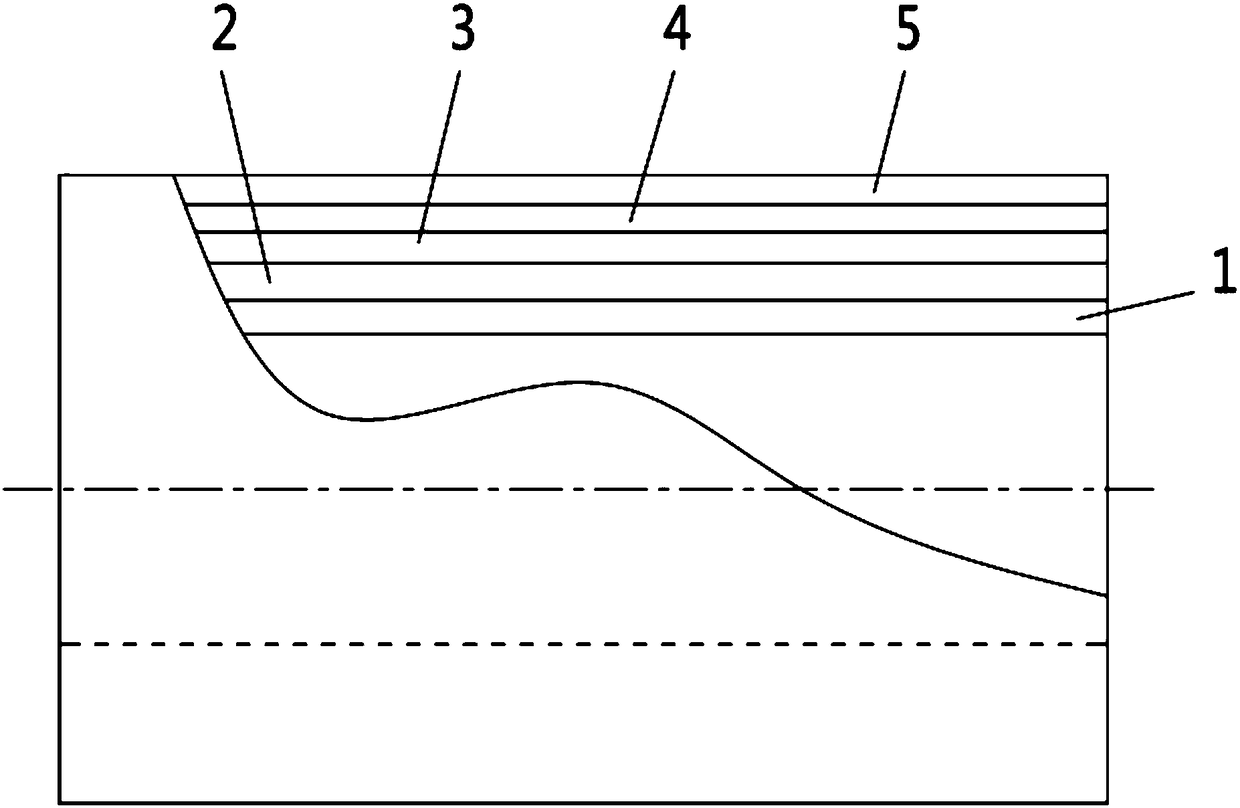

[0012] Such as figure 1 As shown, a kind of multifunctional PBO knitted sleeve involved in this embodiment includes a PBO fiber inner layer 1, and the PBO fiber inner layer 1 is provided with an antibacterial layer 2, a flame retardant layer 3, a steel wire layer 4 and an antibacterial layer in sequence. Grinding layer 5.

[0013] Further, the antibacterial layer 2 is an ammonium dihydrogen phosphate layer, which plays an antibacterial role.

[0014] Further, the flame retardant layer 3 is made of magnesium hydroxide material, which plays a role of flame retardancy.

[0015] Further, the steel wire layer 3 is composed of interwoven steel wires with a diameter of 0.3-0.5 mm, which plays a role in strengthening the structural strength of the knitted sleeve.

[0016] Further, the wear-resistant layer 5 is made of nylon material, which plays th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap