Honeycomb type seal structure suitable for gear box

A sealing structure and gear box technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problem of inability to meet the high sealing requirements of the gear box, and achieve the effect of improving the oil sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

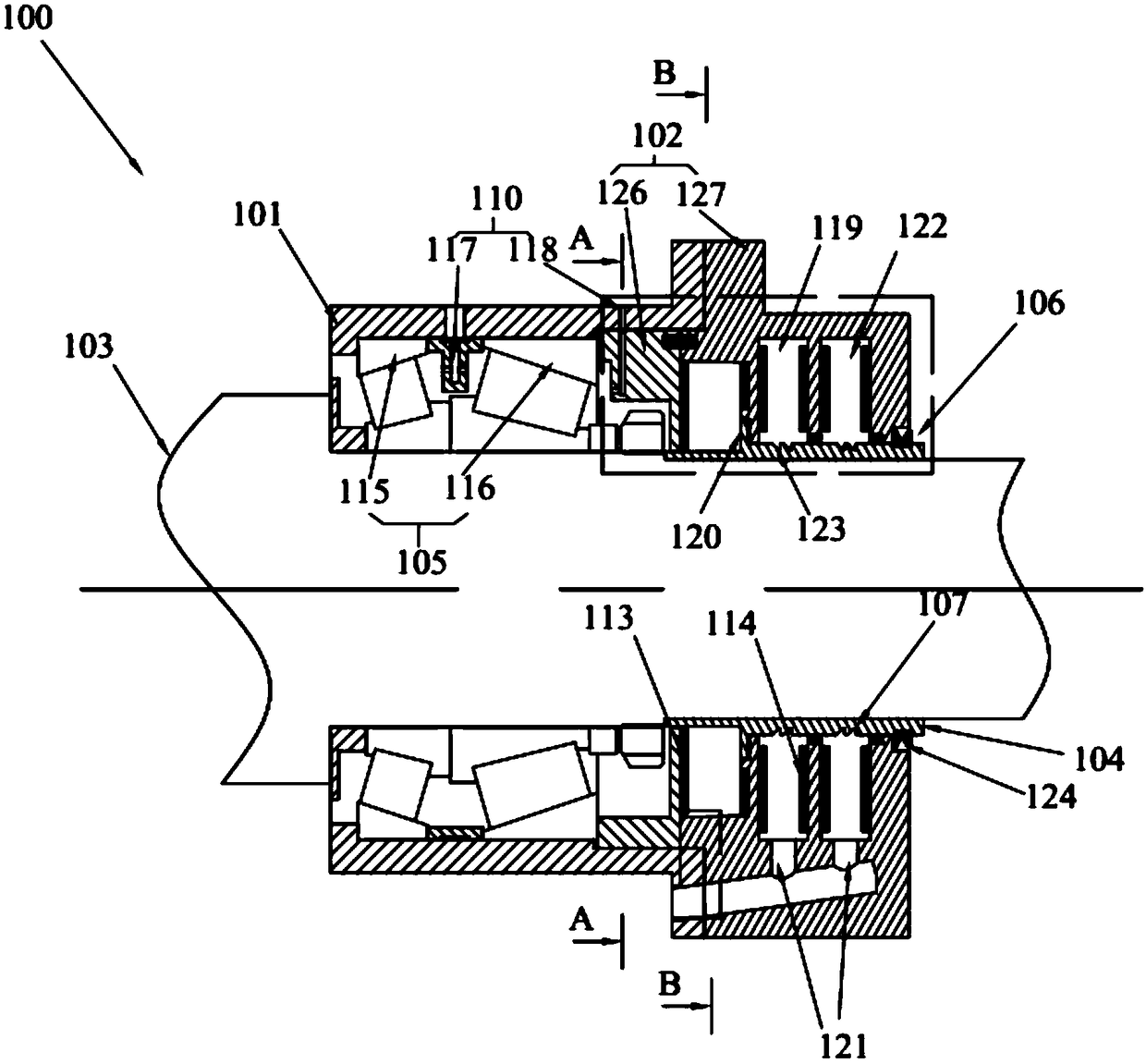

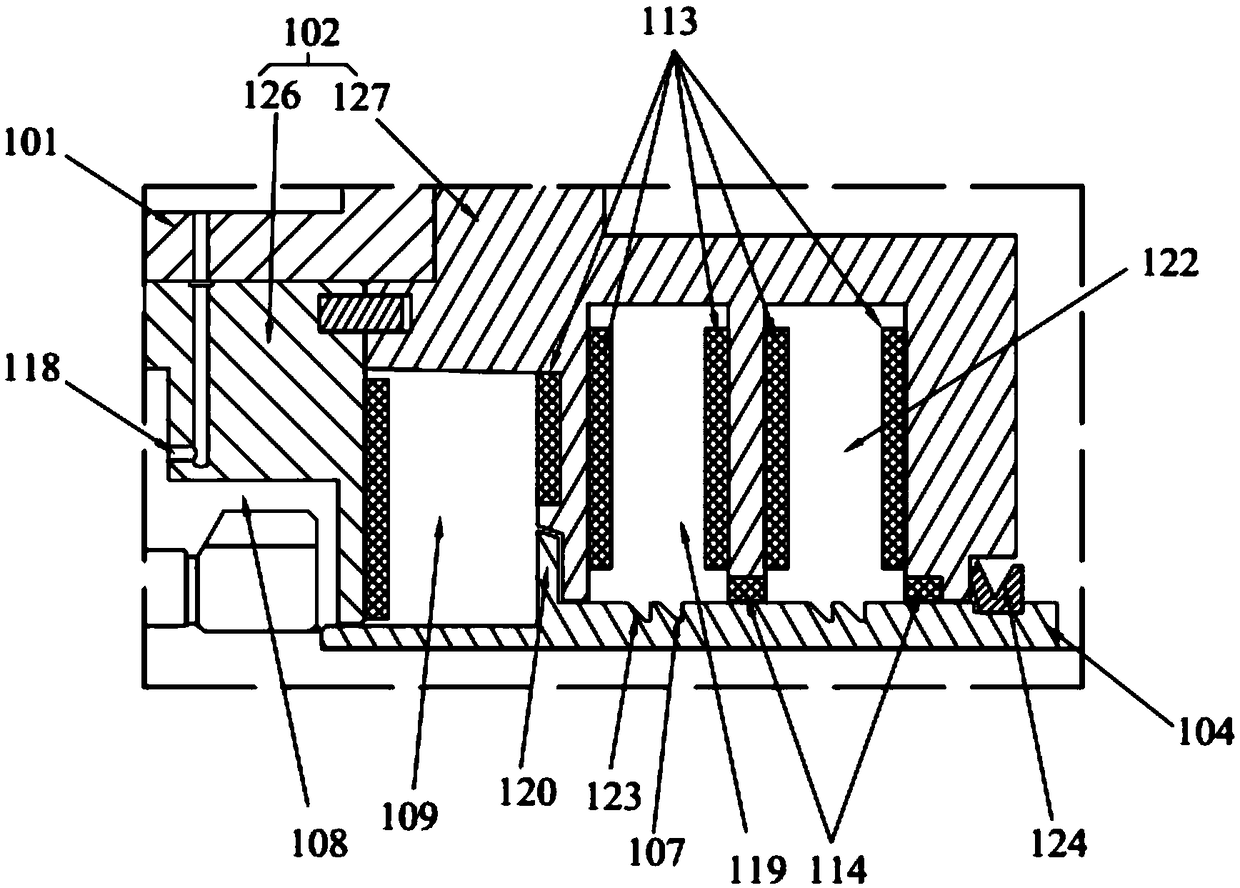

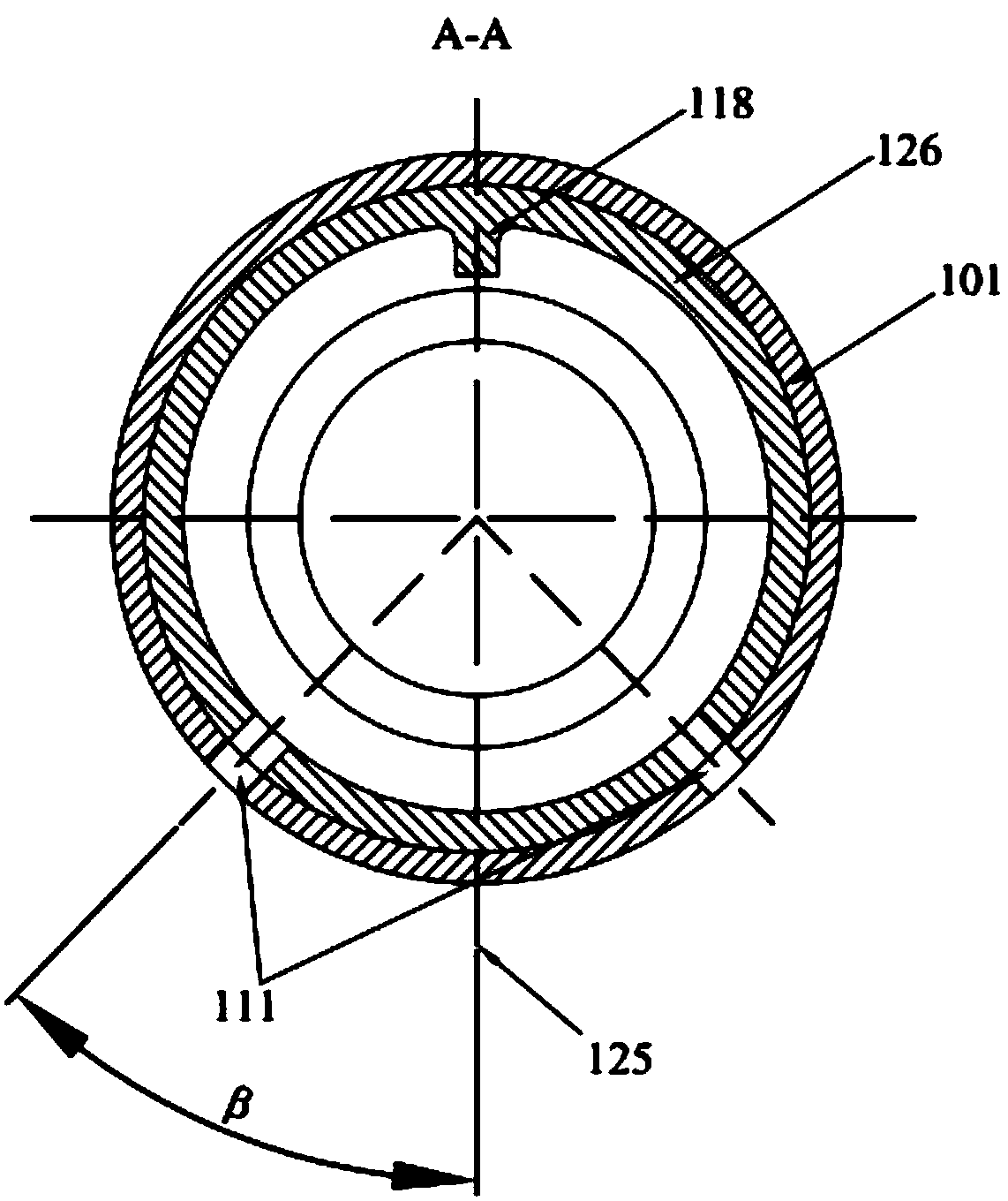

[0024] A honeycomb sealing structure 100 suitable for gear boxes is a sealing system that combines a honeycomb sealing structure, an oil throwing sealing structure and a separate oil return structure. Under the condition of ensuring sufficient lubrication, the gear can be greatly improved. Oil sealing capacity of the tank. In order to ensure that the bearing 105 is fully lubricated, the honeycomb seal structure 100 suitable for the gearbox also includes a forced lubrication structure.

[0025] The honeycomb sealing structure 100 suitable for a gearbox includes: a bearing bush 101, a stationary ring 102, a transmission shaft 103, a moving ring 104 and a bearing 105; the bearing 105 is sleeved on the outer circumference of the transmission shaft 103 and located in the bearing bush 101; Static ring 102 is positioned at the outer periphery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com