Super wear-resistant floating oil seal ring and its production and processing method

A floating oil seal and processing method technology, applied in the field of machinery, can solve the problems of replacement, maintenance difficulties, uneven surface of the sealing work, seepage, oil leakage, etc., to enhance the oil sealing effect and service life, improve hardness and wear resistance. damage performance and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

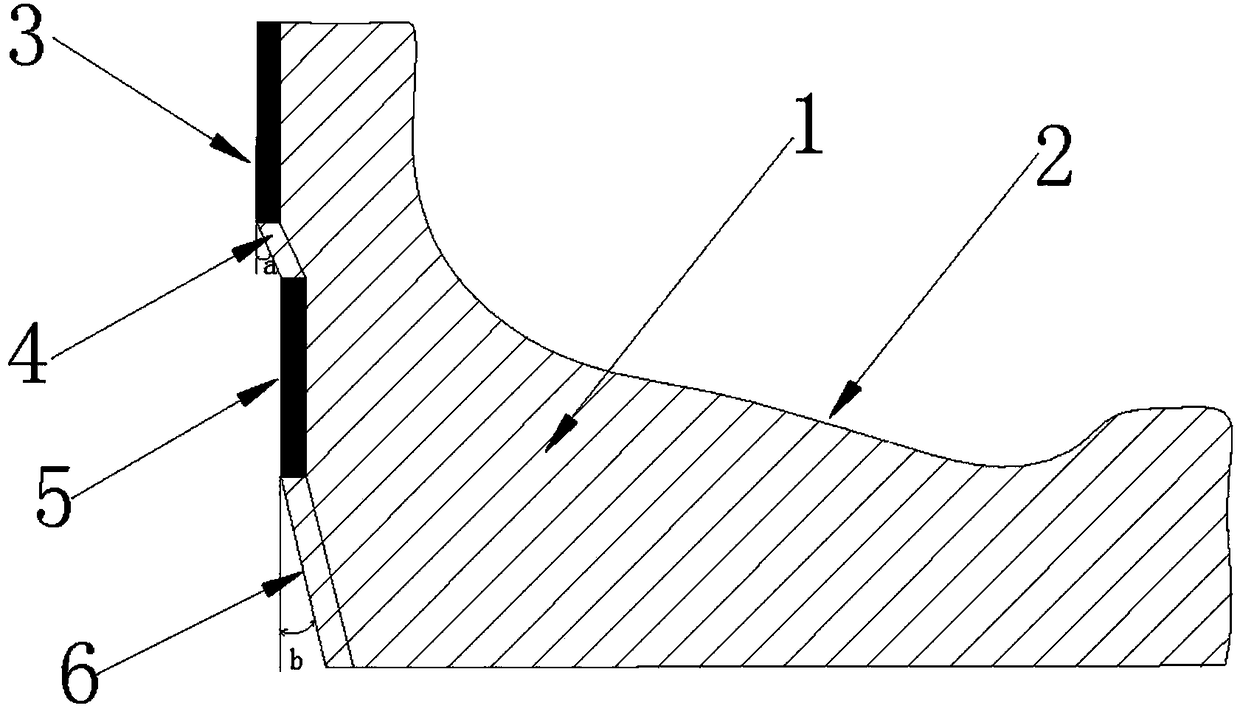

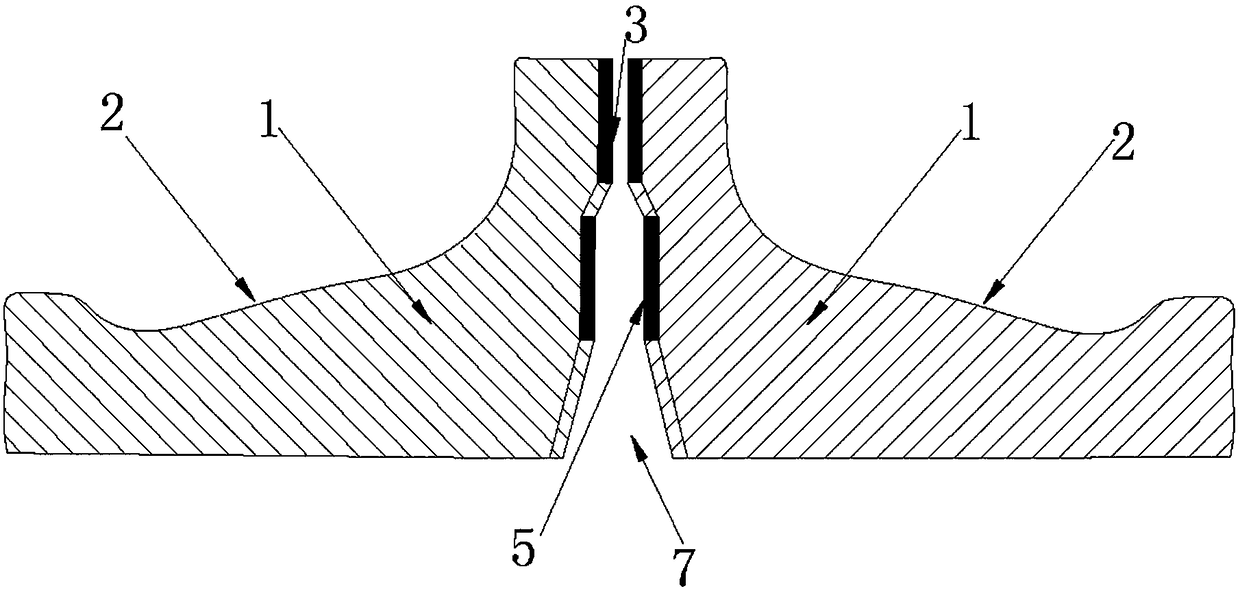

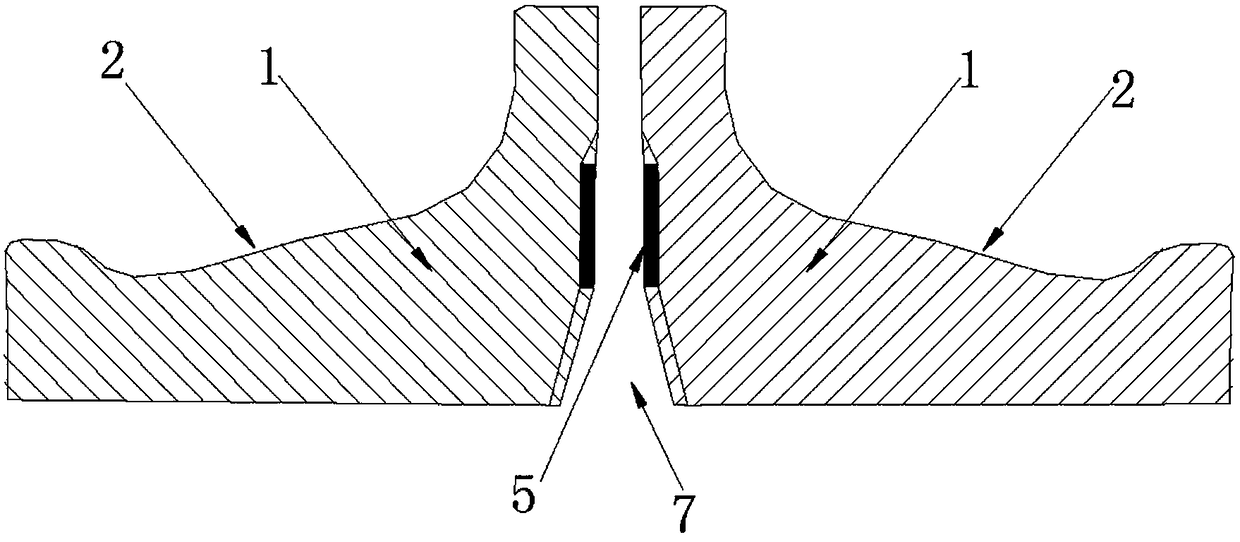

[0036] Embodiment 1, the processing method of the first ring of metal wear-resistant layer and the second ring of metal wear-resistant layer adopts high-frequency electric induction heating on the working surface, and implements surface quenching to optimize the metallurgical phase of the bright band ring on the working surface. The hardness reaches HRC58-HRC65, and the thickness of the metallographic optimization layer below the surface of the first circle of metal wear-resistant layer and the second circle of metal wear-resistant layer is 1-2.5mm.

Embodiment 2

[0037] Embodiment 2, the processing of the first metal wear-resistant layer and the second metal wear-resistant layer adopts the flame spraying method, and the super wear-resistant high-hardness metal powder is sprayed on the first ring working surface of the end face of the floating seal ring by flame spraying Form the first ring of metal wear-resistant layer and the second ring of metal wear-resistant layer on the working surface of the second ring, and the thickness of the first ring of metal wear-resistant layer and the second ring of metal wear-resistant layer is 0.3-0.4mm.

[0038]The invention relates to a super wear-resistant floating oil seal ring and its production and processing method. The frictional contact surface of the floating oil seal ring is processed into two layers of metal wear-resistant layers in a stepped shape, so that the service life of the floating oil seal ring is doubled, and the metal wear-resistant layer is formed. The bright belt of the oil seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com