Sealing test assembly and system thereof

A technology for sealing testing and components, which is applied in the direction of using liquid/vacuum for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve the problems of high cost, low efficiency, poor test effect accuracy, etc., to improve efficiency. , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

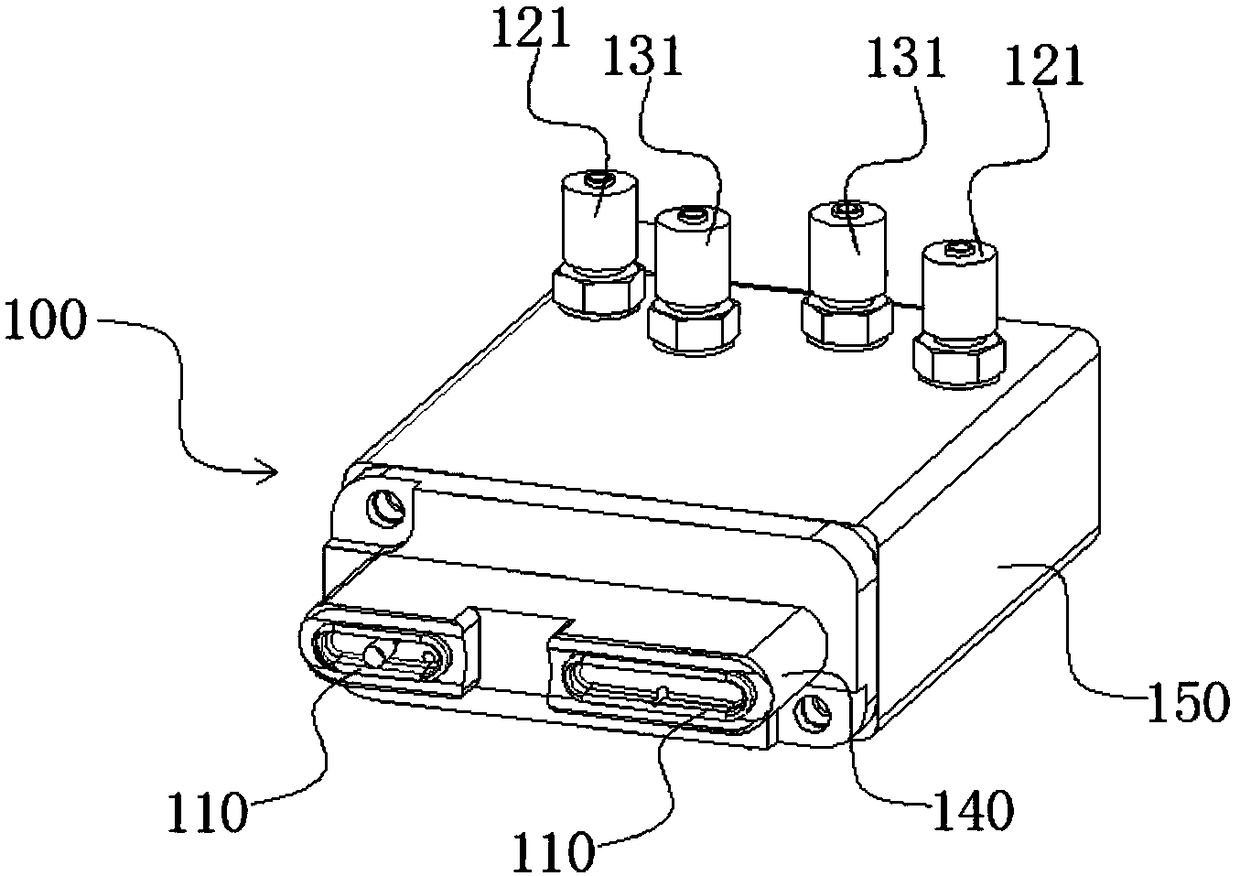

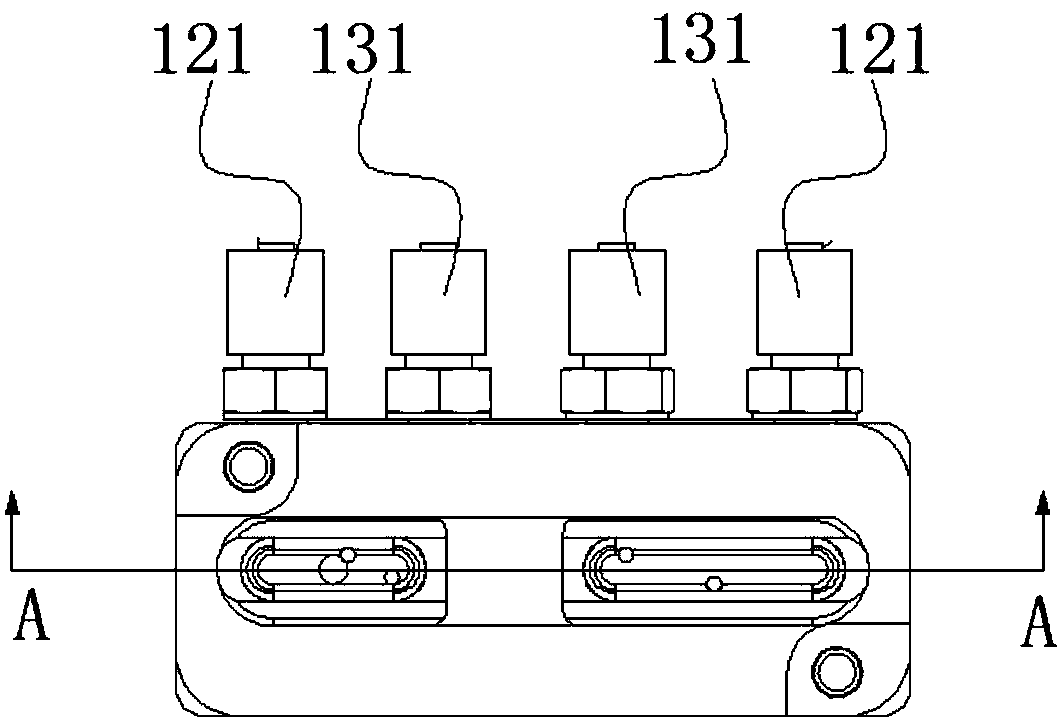

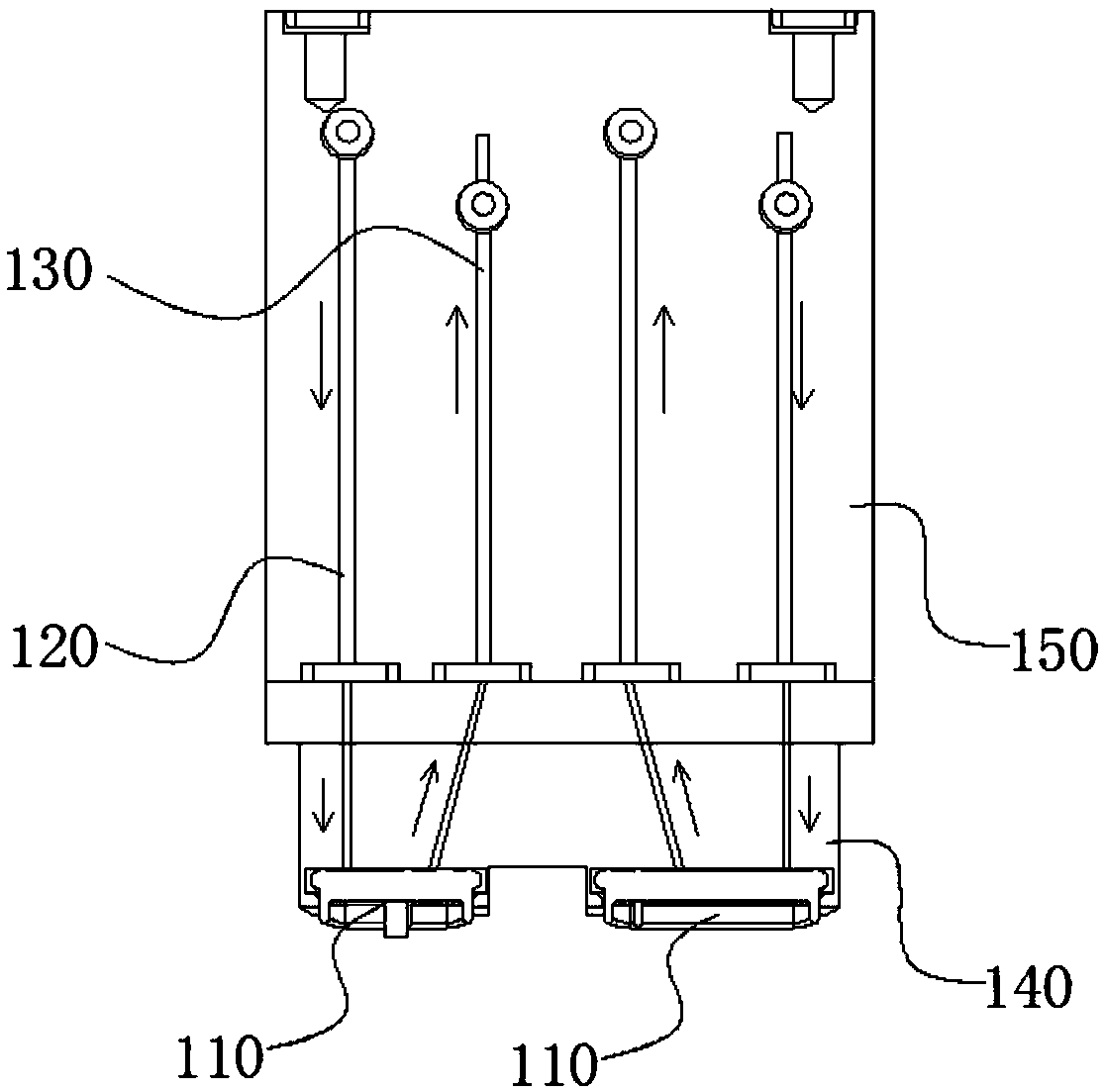

[0043] Such as Figure 1 to Figure 3 As shown, the first embodiment provides a sealing test assembly 100, including: at least one test point seal ring, the test point seal ring has a seal ring body 110 with an open end, and each seal ring body 110 is connected to the product to be tested. A closed cavity containing test points is formed between them; wherein, each sealing ring body 110 is provided with a water inlet and a water outlet connected to the sealed cavity, and the water inlet is arranged at the bottom end of the sealing ring body 110, so that Water enters the airtight cavity from the bottom end, and the water outlet is arranged at the top end of the sealing ring body 110 to allow water to flow out from the top end.

[0044] In the seal test assembly 100, a sealed cavity containing a test point can be formed between the sealing ring body 110 and the product to be tested, and each sealing ring body 110 is provided with a water inlet and a water outlet connected to the ...

Embodiment 2

[0062] Such as Figure 4 to Figure 7 As shown, the second embodiment provides a sealing test system, including: a waterway assembly and the above-mentioned sealing test assembly 100, a closed cavity containing test points can be formed between the sealing test assembly 100 and the product to be tested; the waterway assembly includes The water pipeline and the water outlet pipeline, the water inlet pipeline is connected with the water inlet part of the closed cavity, and the water outlet pipeline is connected with the water outlet part of the closed cavity, and is used to discharge the water in the closed cavity; the water inlet pipeline includes positive pressure The pipeline, the positive pressure pipeline is used to inject water into the closed cavity, and apply pressure to the closed cavity filled with water and keep the pressure, and the water inlet pipeline is connected with a pressure element for monitoring the pressure in the closed cavity.

[0063] In this sealing test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com