High-frequency non-contact rapid heating device and method for distribution transformer terminal

A technology for distribution transformers and rapid heating, which is applied in the direction of induction heating devices, induction heating, induction heating control, etc., which can solve the problems of finding material differences and achieve non-destructive, non-contact, and rapid heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

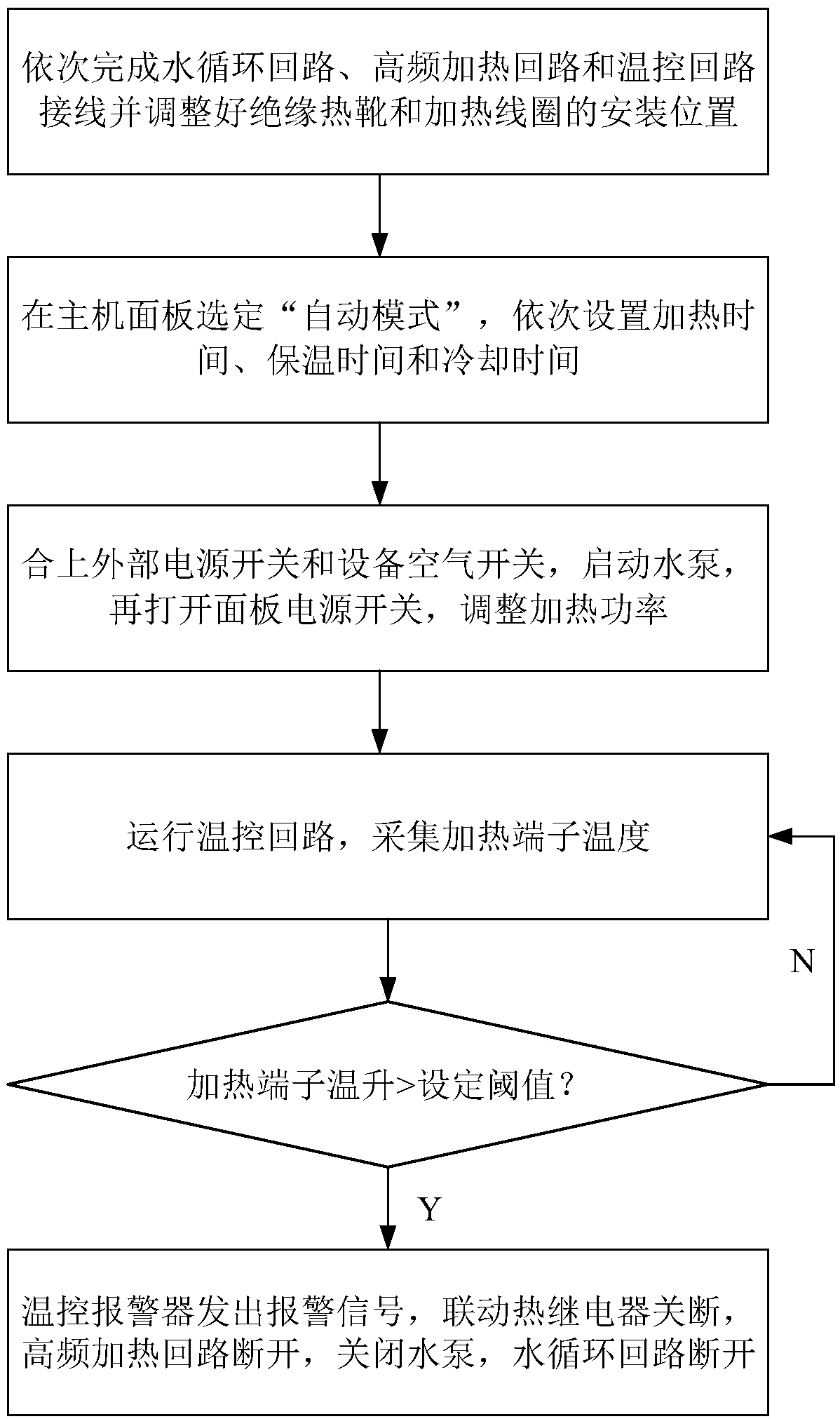

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

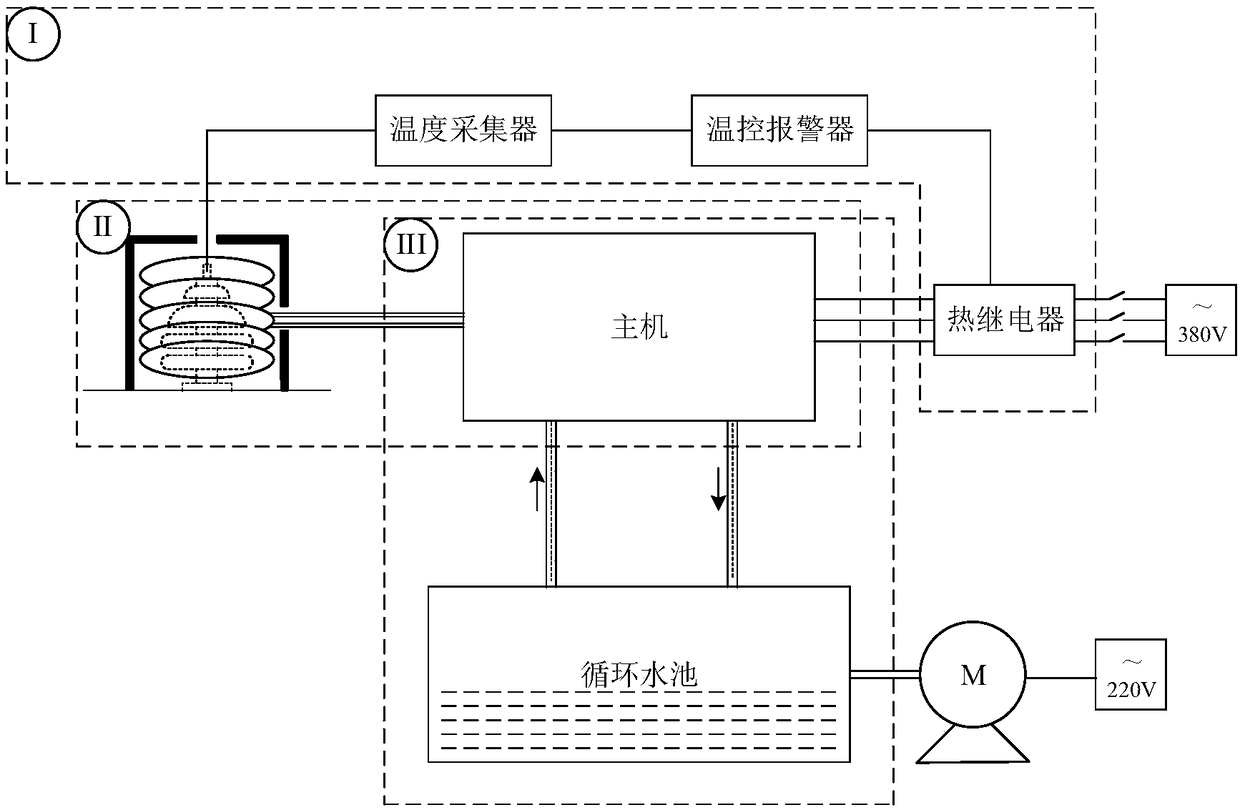

[0022] This embodiment provides a high-frequency non-contact rapid heating device for distribution transformer terminals, which specifically includes:

[0023] Temperature control device: mainly includes temperature collector, temperature control alarm and thermal relay, which can monitor and shut down the heating temperature;

[0024] High-frequency heating device: mainly includes the host, induction heating coil and insulating hot shoe, which can realize rapid and efficient heating of distribution transformer terminals;

[0025] Water circulation device: It mainly includes a circulating water pool and a main engine to realize heating and cooling of the high-frequency heating circuit.

[0026] Moreover, the induction heating coil in the high-frequency heating device can heat the terminals of the distribution transformer, which has the characteristics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com