Die device and method for using same

A mold, mold side technology, applied in the field of mold devices, can solve the problems of deterioration of dimensional accuracy and shape accuracy, uneven wear, burrs on products, etc., and achieve the effect of suppressing misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

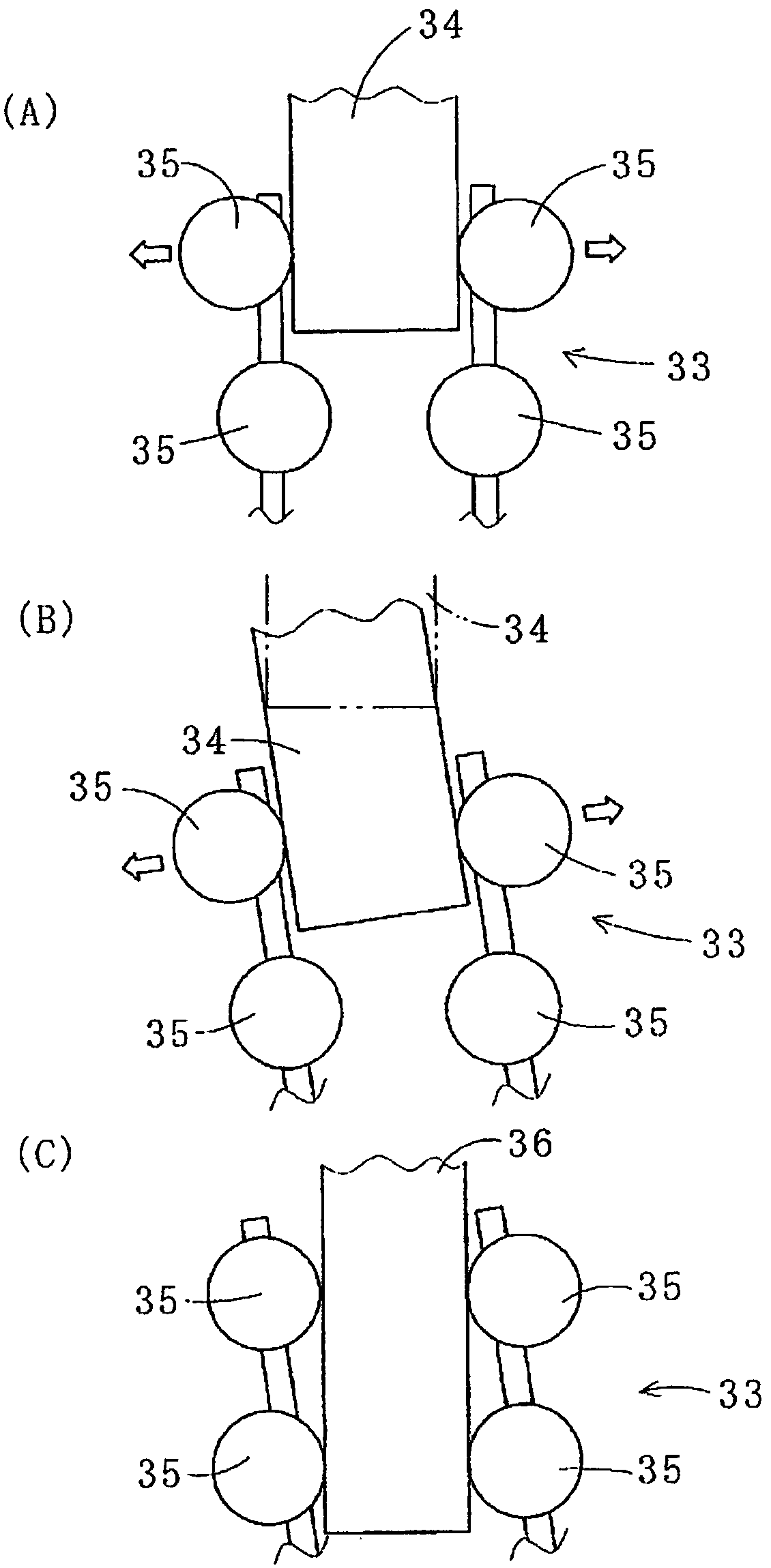

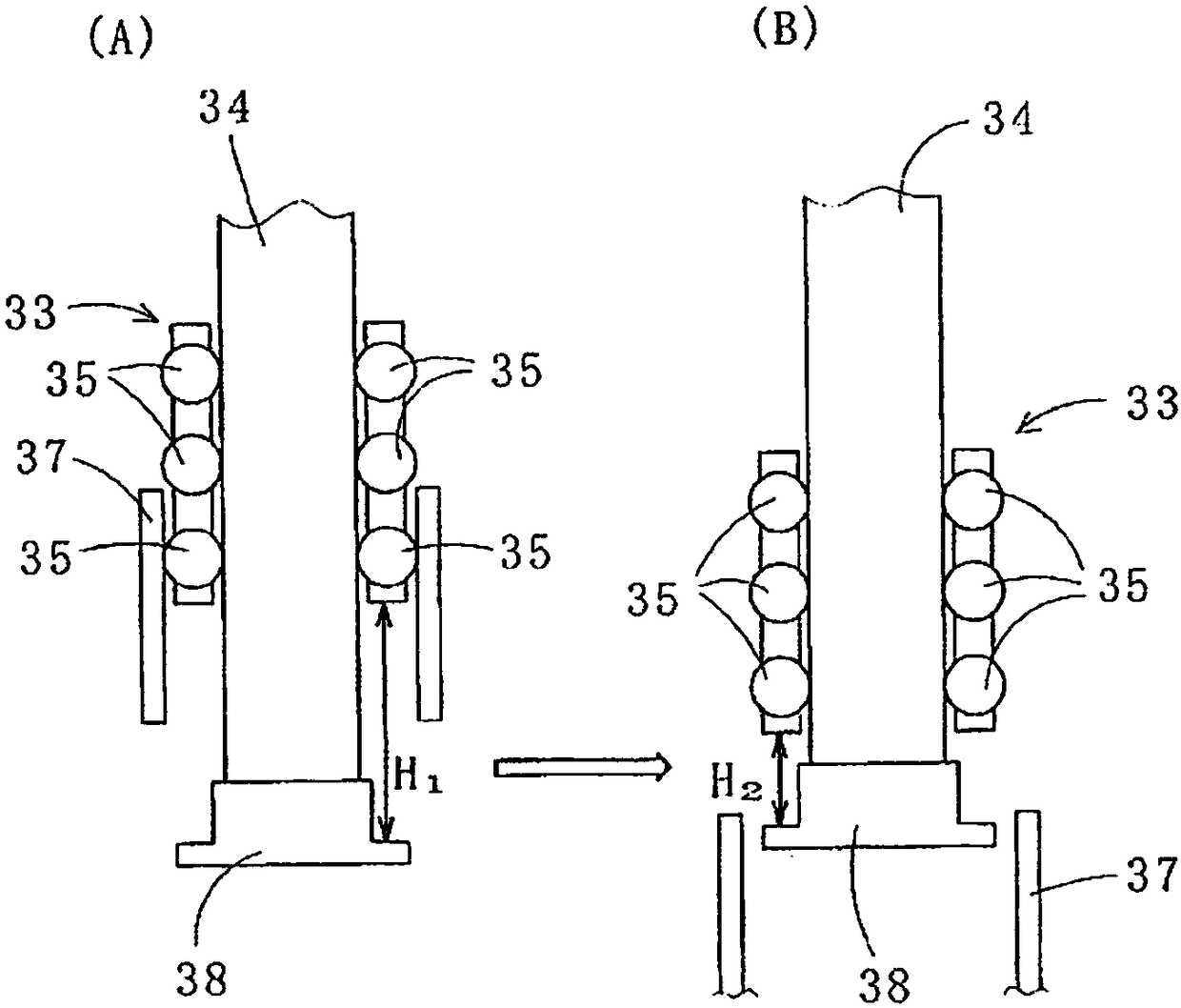

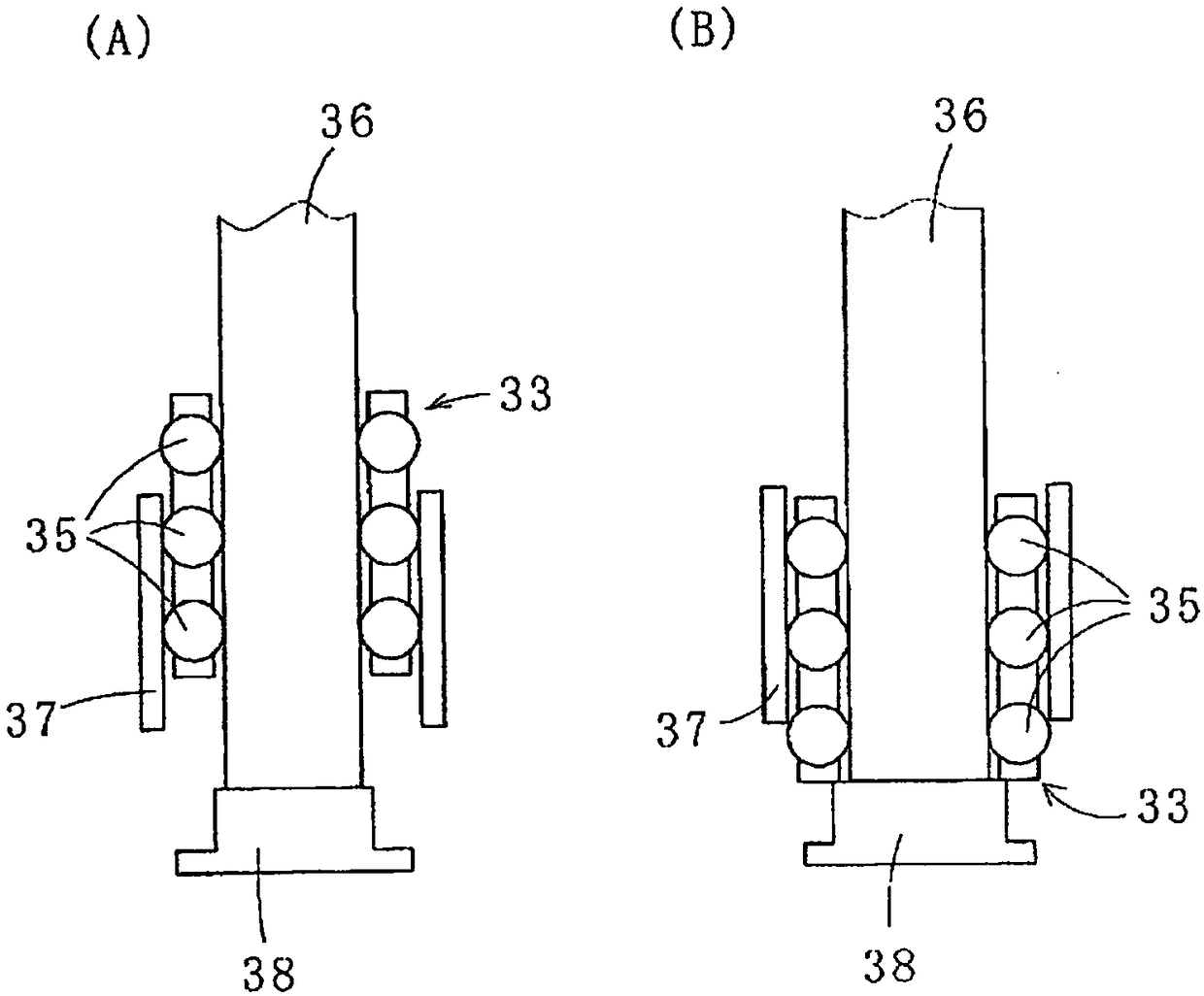

[0091] figure 1 (A) is a schematic view illustrating a state in which a guide post having an outer diameter such that the balls 35 of the ball retainer 33 are largely moved outward in the radial direction thereof is inserted into the ball cage 33 in a vertical state .

[0092] figure 1(A) Figure shows that the guide post 34 is inserted into the guide sleeve 37 through the ball retainer 33 along the axial direction of the guide sleeve 37 (see figure 2 (A) and 2(B)). In this case, the balls 35 of the ball cage 33 move (squeezed) radially outward of the ball cage 33 (guide pin 34 ) along the outer diameter of the guide pin 34 while rotating in contact with the guide pin 34 . out). Pressing force is applied to the inner surface of the guide sleeve 37 through the balls 35 moving outward in the radial direction. The retaining force from the guide sleeve 37 is applied to the guide post 34 due to the reaction force of the pressing force. As a result, the guide post 34 can smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com