Device for separating lubricating oil streams, and turbocharger comprising such a device

An exhaust gas turbine and supercharger technology, which is applied to gas turbine devices, machines/engines, engine components, etc., can solve problems such as lubricating oil blockage, turbine casing leakage, etc., and achieve the effect of preventing mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

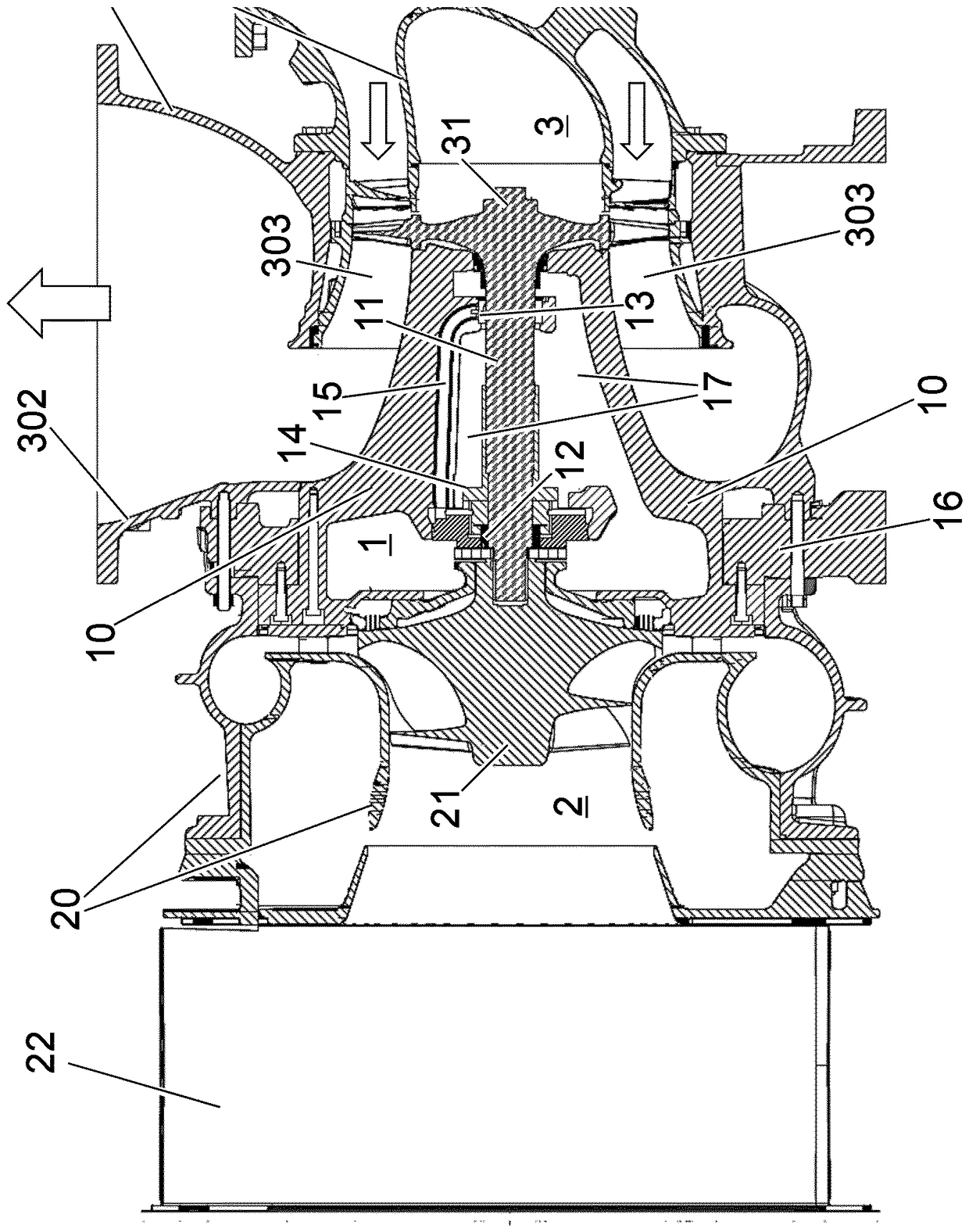

[0020] figure 1 Shows a schematic sectional view of an exhaust gas turbocharger according to the prior art with a compressor 2, a bearing 1, and an axial turbine 3, with stationary housing parts (compression machine housing 20, bearing housing 10 and turbine housing 30). The compressor wheel 21 , the turbine wheel 31 and the shaft 11 connecting the compressor wheel and the turbine wheel to one another are components of the rotor of the exhaust gas turbocharger. From the compressor housing 20 , which accommodates the compressor wheel 21 , the shaft 11 is guided via the bearing housing 10 into the turbine housing 30 , which accommodates the turbine wheel 31 . In addition, a filter silencer 22 is shown as an optional component of the exhaust gas turbocharger, which is connected to the compressor housing and serves to damp the significant sound level.

[0021] A seal is present at the transition between the three stationary housing parts mentioned above due to the passage of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com