Multi-functional multi-purpose multi-stage rotary packed bed reactor device and method for performing multi-phase multi-component reaction by using the same

A technology of rotating packed bed and multi-component reaction, which is applied in the direction of chemical method, separation method, chemical instrument and method for reacting liquid and gas medium, and can solve the problem of single liquid inlet, liquid outlet, limited rotating packed bed Use and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

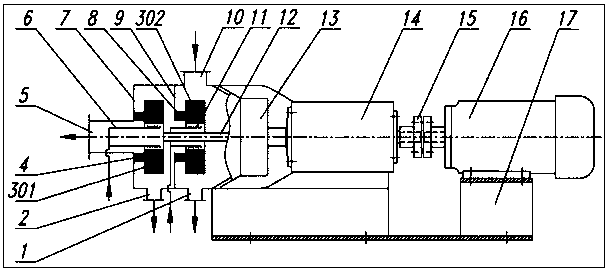

[0036] see figure 1 Shown, a kind of multi-stage rotating packed bed reactor device of multifunctional purpose, comprises motor 16, shaft coupling 15, bearing housing 14, base 17 and multistage rotating packed bed; The output shaft of described motor 16 and coupling The device 15 is fixedly connected, the output shaft of the coupling 15 is fixed and coaxially connected with the rotating shaft of the multistage rotary packed bed through the bearing seat 14, and the motor 16, the bearing seat 14 and the multistage rotary packed bed are arranged on the base 17 ; The multi-stage rotary packed bed includes a housing 7, a first-stage rotor 301, a second-stage rotor 302 and a rotating shaft 12; both the first-stage rotor 301 and the second-stage rotor 302 are provided with adsorption fillers; A first-stage liquid distributor 6 is provided at the inner edge of the first-stage rotor 301, and a second-stage liquid distributor 11 is provided at the inner edge of the second-stage rotor 30...

Embodiment 2

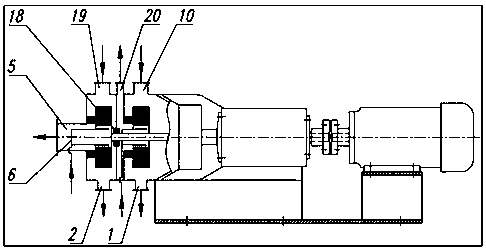

[0041] see figure 2 Shown, repeat embodiment 1, its difference is:

[0042] The casing on the left side of the first-stage rotor 301 is provided with a first-stage gas outlet 5, and the casing above the first-stage rotor 301 is provided with a first-stage gas inlet 19; the casing around the second-stage rotor 302 The upper part of the body is provided with a second-stage gas inlet 10, and two partition plates 9 are provided between the first-stage rotor 301 and the second-stage rotor 302, and a channel is formed between the two partition plates 9, and the channel is in the casing. The opening on the body 7 is the second-stage gas outlet 20; a third sealing member 18 is provided between the left partition plate and the rotating shaft 12. The difference between this embodiment and Embodiment 1 is that a first-stage gas inlet 19 is provided on the casing around the first-stage rotor; through the setting of two partition plates, the first-stage gas inlet and the first-stage rotor ...

Embodiment 3

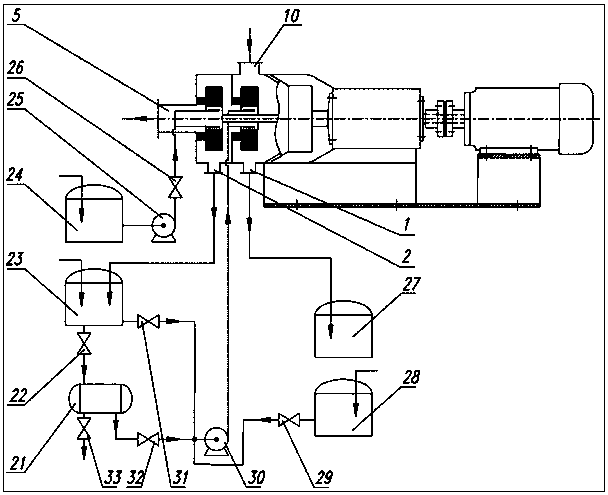

[0044] see figure 1 , image 3 Shown, a kind of method that utilizes the multistage rotating packed bed reactor device of above-mentioned multifunctional use to carry out heterogeneous multicomponent reaction, comprises the steps:

[0045] The liquid enters the first stage rotor 301 from the first stage raw material tank 24 through the first pump 25 and the first valve 26, and under the action of centrifugal force, the liquid passes through the first stage rotor 301 and flows out from the first stage liquid outlet 2 into the first stage Level liquid recovery tank 23; if the liquid needs to be heated up or down (the temperature up or down is to adjust the temperature of the liquid in the range of -50°C to 500°C, preferably -5°C to 200°C), it will be transported through the control of the second valve 22 to the heat exchanger 21, through the fifth valve 32, and pumped into the second-stage rotor 302 under the action of the second pump 30; the sixth valve 33 is set under the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com