Chain link integrated online roll gap instrument

A roll gap meter and chain link technology, which is applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, metal processing equipment, etc. Low-level problems, to achieve the effect of solving the overall disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

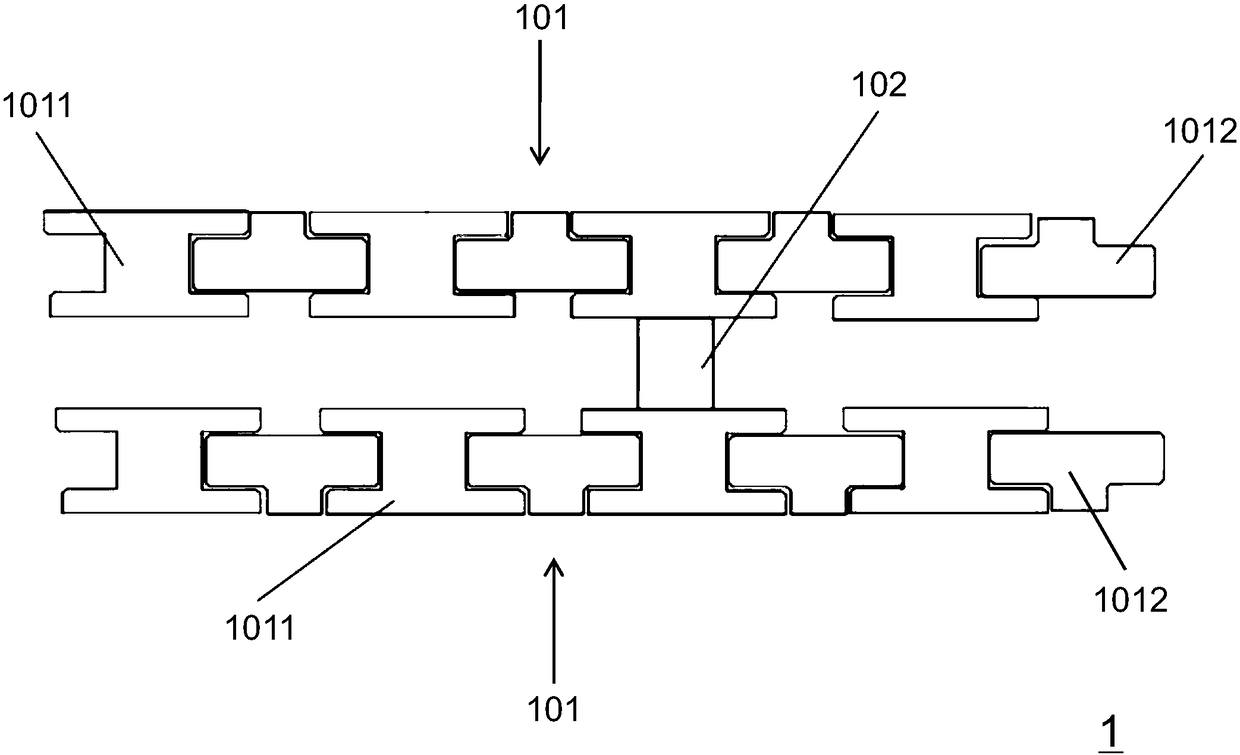

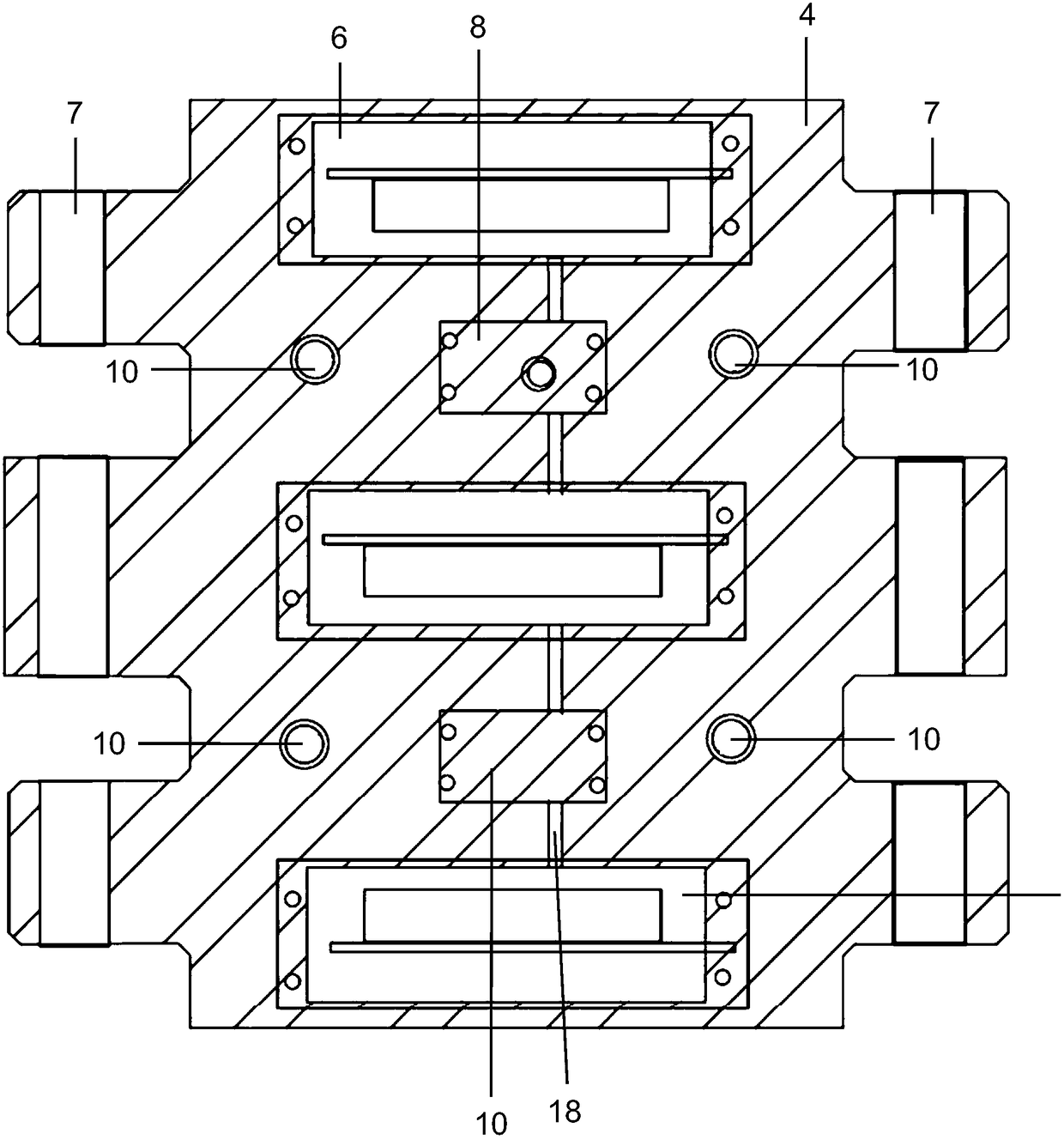

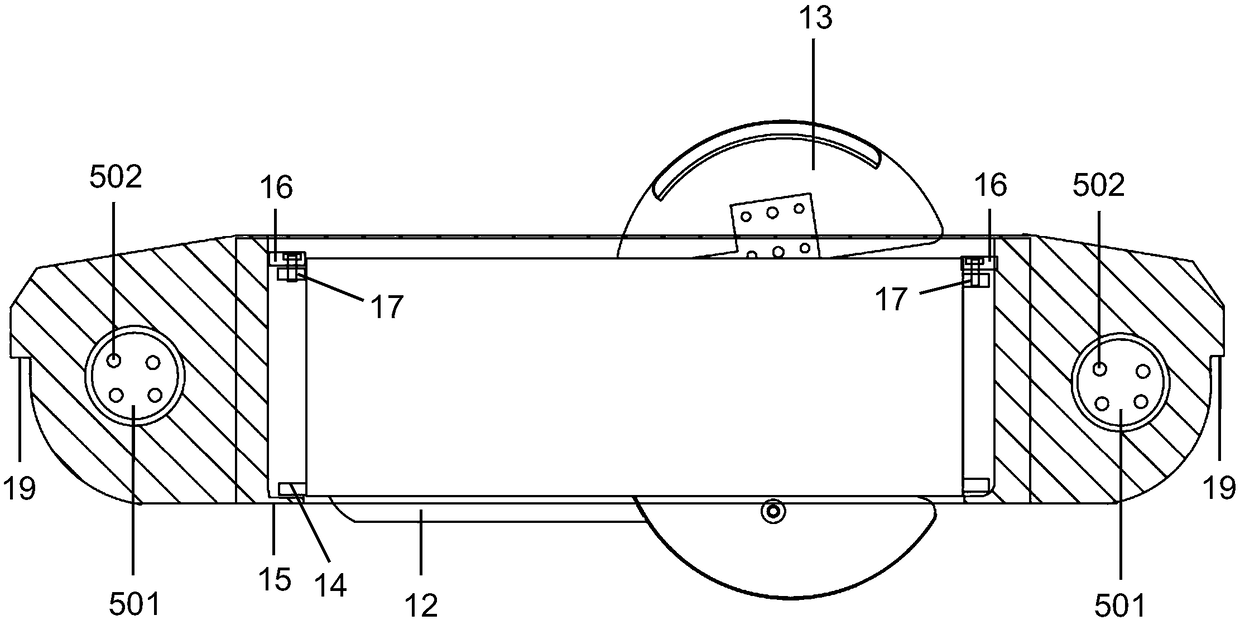

[0025] Please combine Figure 1 to Figure 6 As shown, an online roll gap meter with integrated chain links provided by the present invention is connected to a dummy bar 1, and the dummy bar 1 for slab continuous casting is used to pull the slab when the casting machine starts pouring, and guides the The spindle bar 1 includes two chains 101, and several connecting pieces 102 connected between the two chains 101, and the dummy head 2 is installed on the head of the dummy bar 1 to block the lower opening of the crystallizer 3, And form a billet hook with the molten steel injected into the crystallizer 3 and solidified. In the subsequent pouring process, the billet is pulled out of the casting machine. The chain 101 of the dummy bar 1 includes several H-shaped joints 1011 and several T-shaped joints 1012, each H-shaped section 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com