Servo sawing jig

A jig and sawing technology, which is applied in the direction of metal sawing equipment, manufacturing tools, sawing machine accessories, etc., can solve the problems of unusable jigs, difficulties in automatic pick-up of jigs, and poor versatility of jigs, etc. The effect of using versatility, ensuring production capacity and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

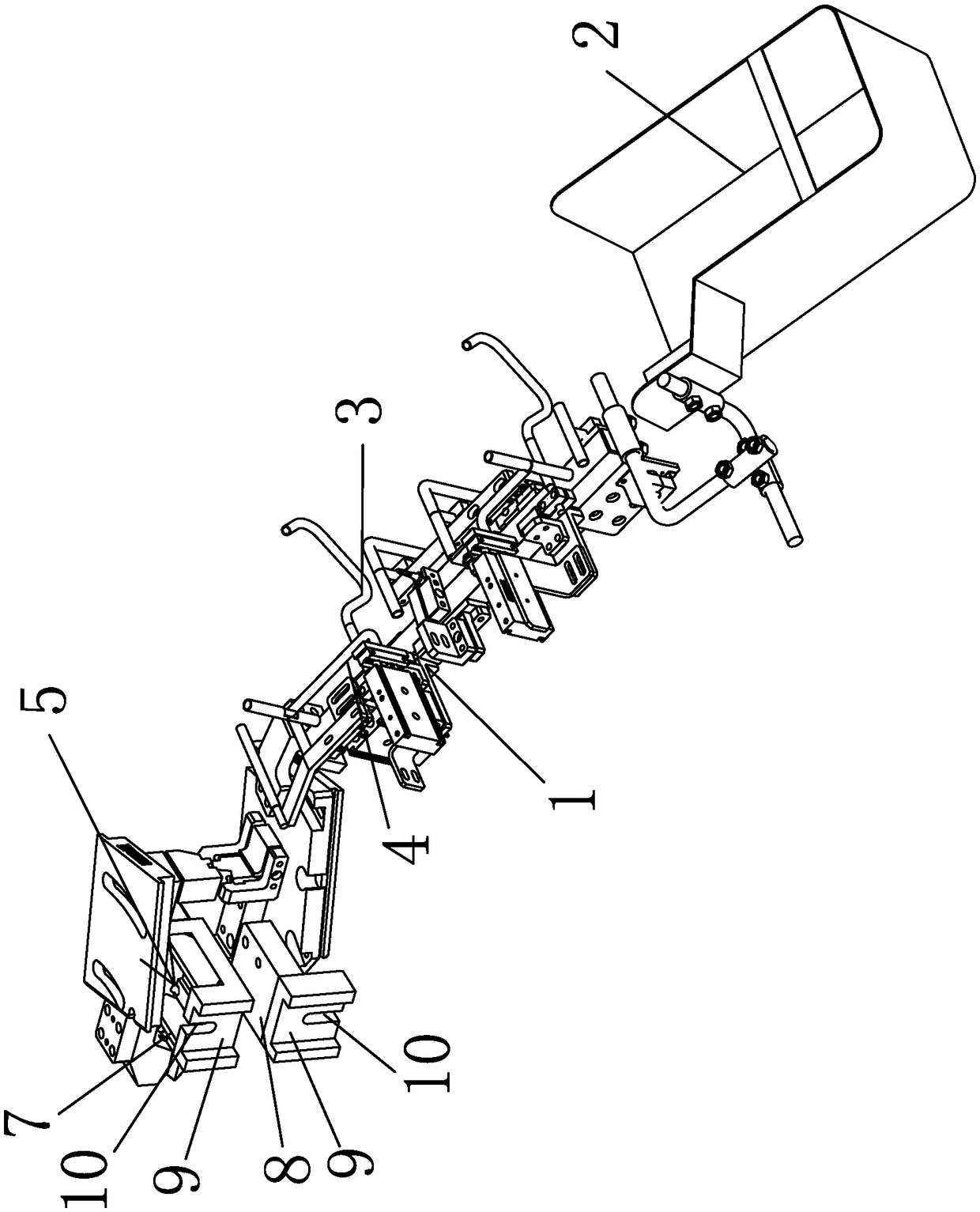

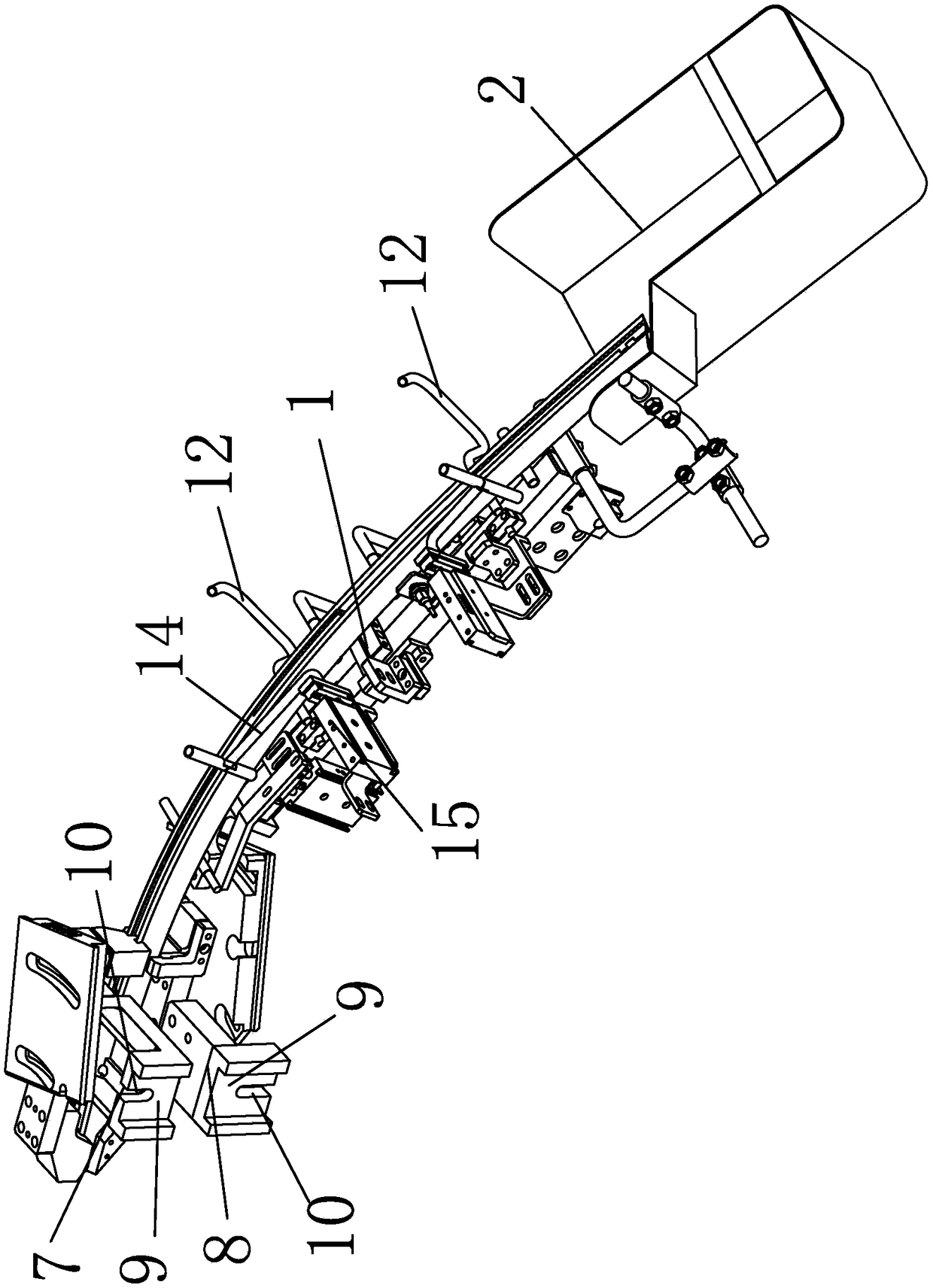

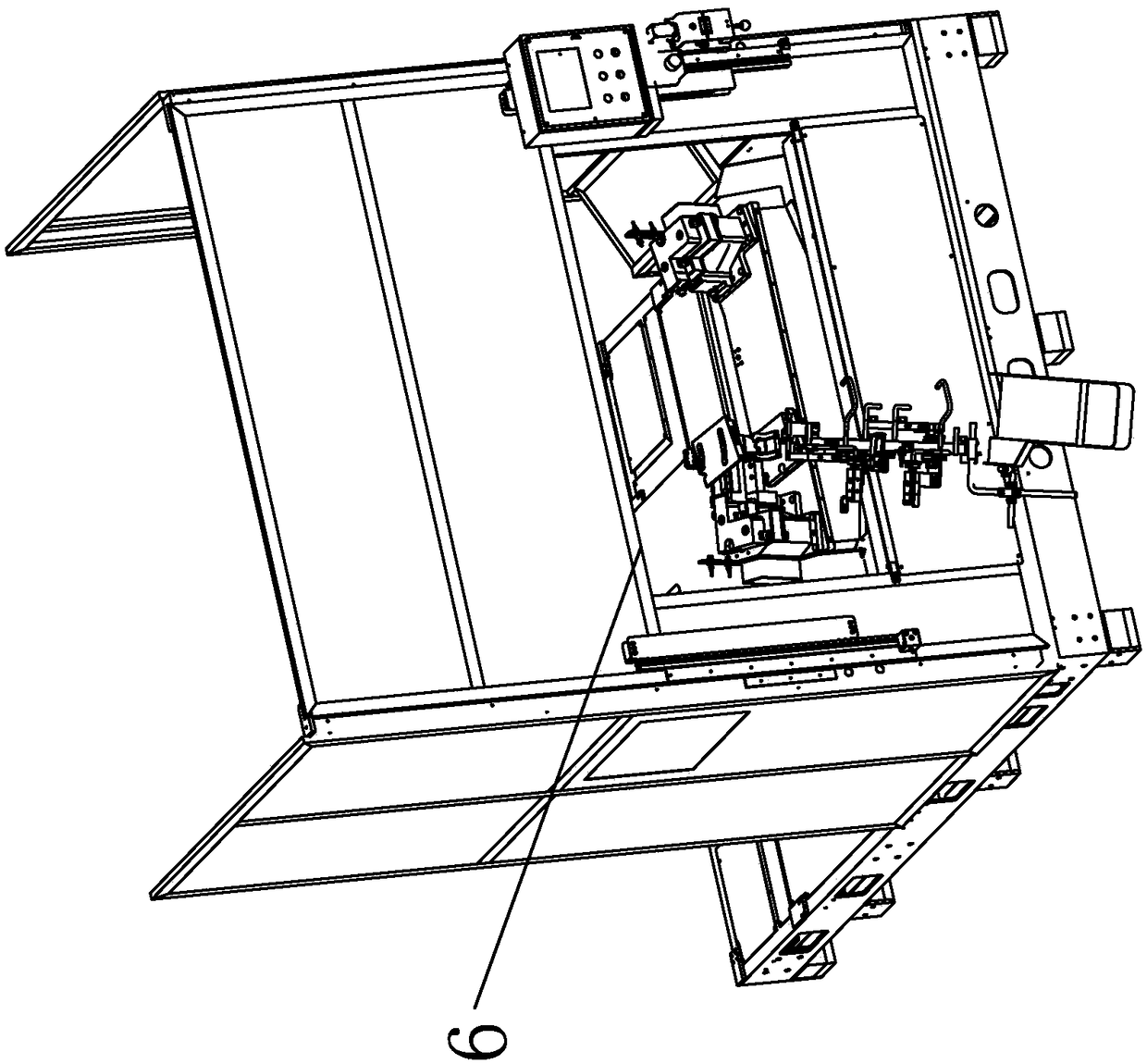

[0016] In the figure, fixture main body 1; hopper 2; lifting and sliding device 3; lateral pushing device 4; transfer connection device 5; robot sawing system 6; Locking groove 9; locking groove 10; locking block 11; holding up material rod 12; supporting cylinder 13; pushing out material rod 14; horizontal cylinder 15.

[0017] Such as figure 1 and Figure 4 As shown, the servo sawing jig includes a jig main body 1, a hopper 2 is provided at the lower end of the jig main body 1, and the jig main body 1 is provided with a lifting and sliding device 3 and a lateral pushing device 4. The upper end of the main body 1 is connected to the connecting device 5. An innovation of this patent is to set the connecting device 5, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com