Control system for butting mechanism of reconfigurable robot and control method of control system

A technology for reconstructing robots and docking mechanisms. It is applied in the direction of program-controlled manipulators, manipulators, and manufacturing tools. It can solve problems such as single structure and function, and achieve the effects of accurate and reliable docking, strong adaptability to external environment, and strong load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

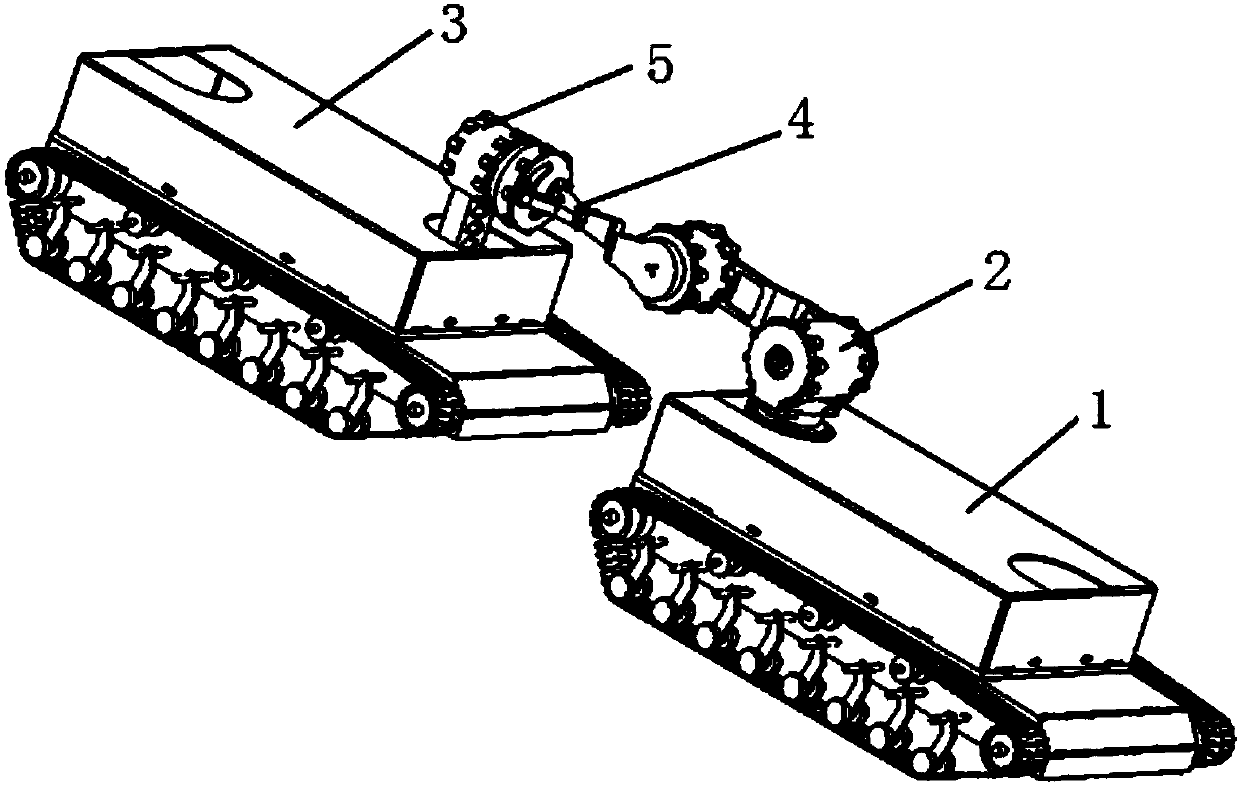

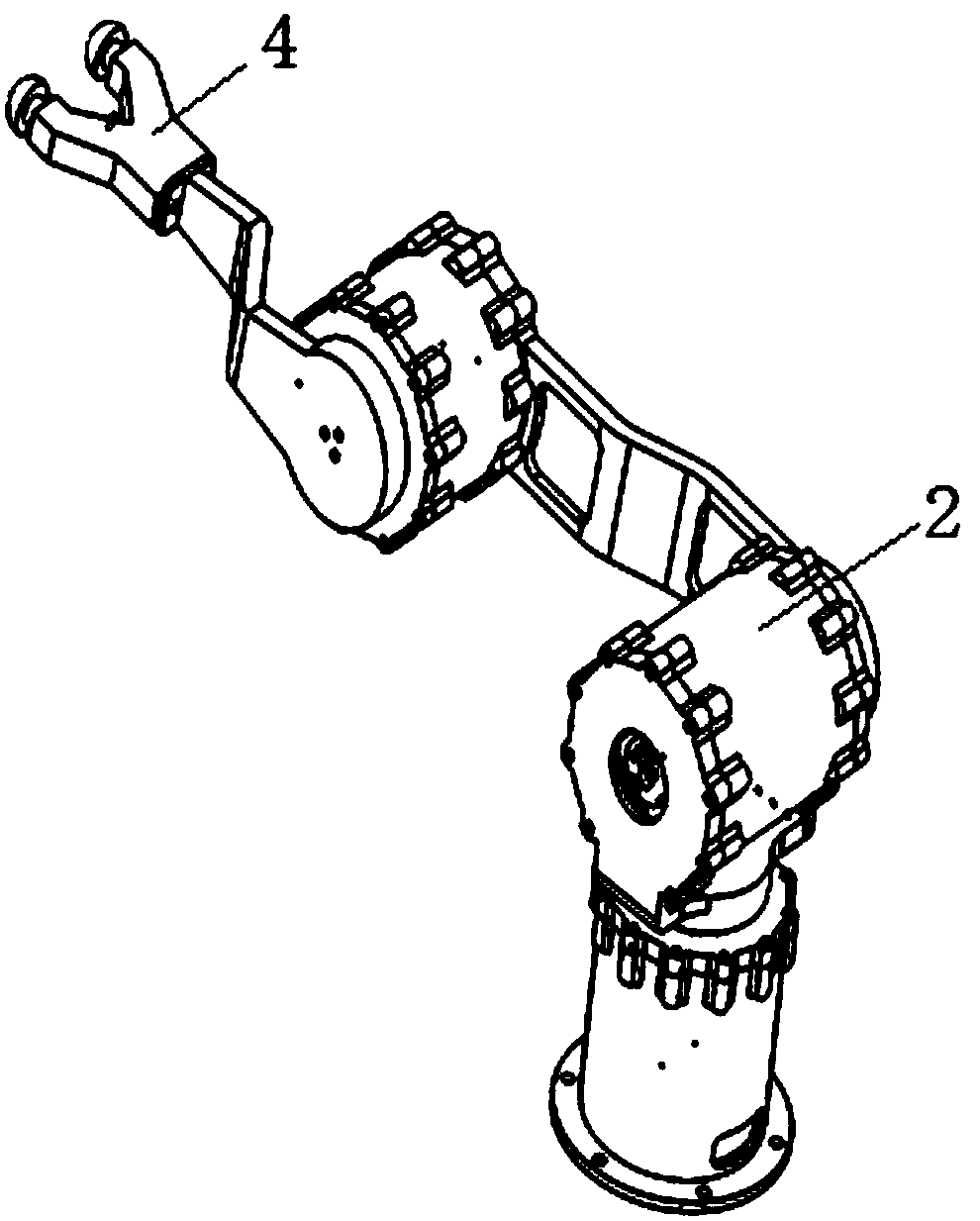

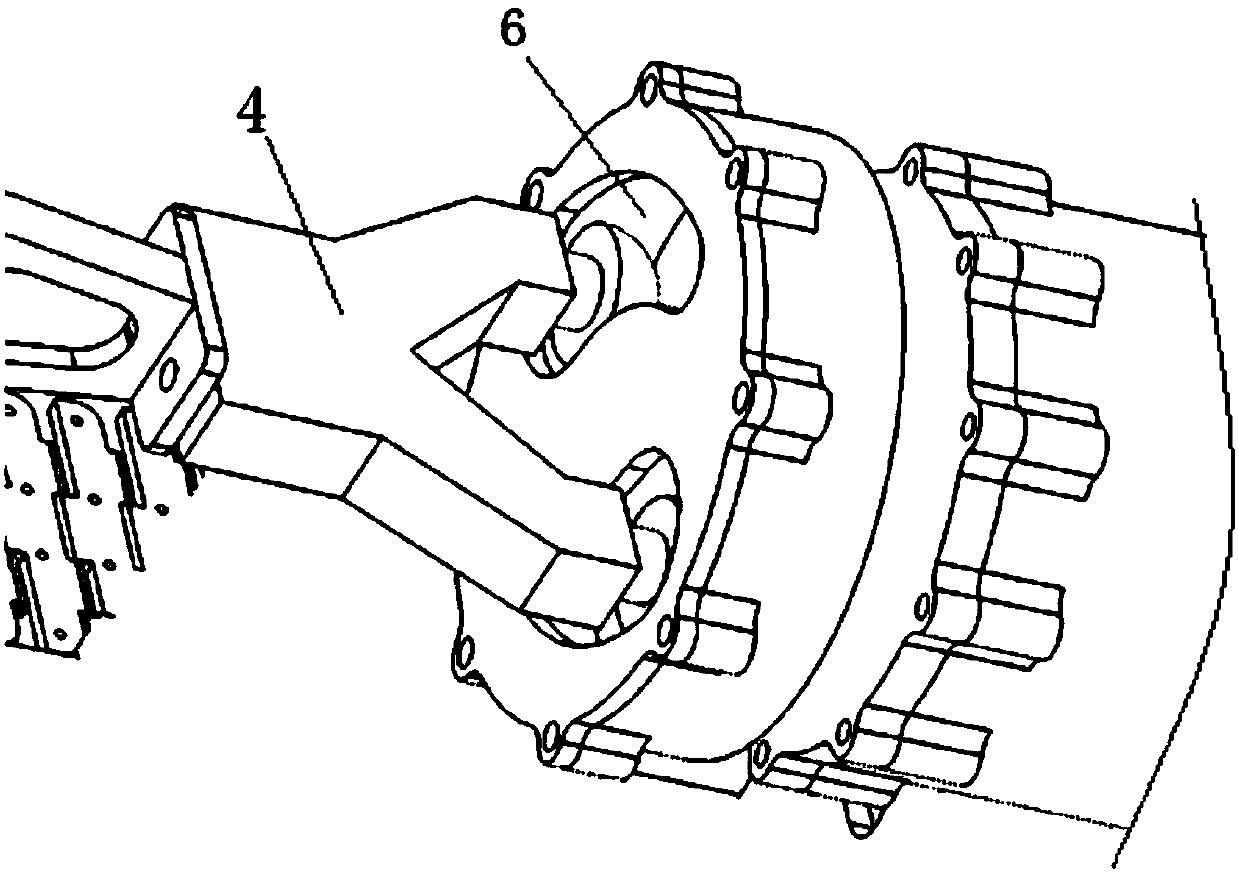

[0024] The reconfigurable robot docking mechanism applied in the present invention is as figure 1 As shown, including active mobile modules and passive mobile modules. The active mobile module 1 is connected to the robot arm 2, and the configuration of the robot arm 2 is as follows: figure 2 As shown, the mechanical arm 2 has three degrees of freedom, and each connecting rod (three connecting rods) is driven in series, which can realize a large range of spatial movement. The end of the mechanical arm 2 is connected with a passive connector 4 (ie, a claw), which adopts a symmetrical "Y"-shaped structure ("Y"-shaped claw). The passive mobile module 3 is provided with an active connector 5, and the active connector 5 adopts a gear structure with two gradually changing grooves 6 (see image 3 ), the gear is driven by a stepper motor.

[0025] The locking function of the docking mechanism is completed by the passive connector 4 installed on the active mobile module 1 and the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com