A kind of preparation method of mxene/ps nanocomposite electrorheological material

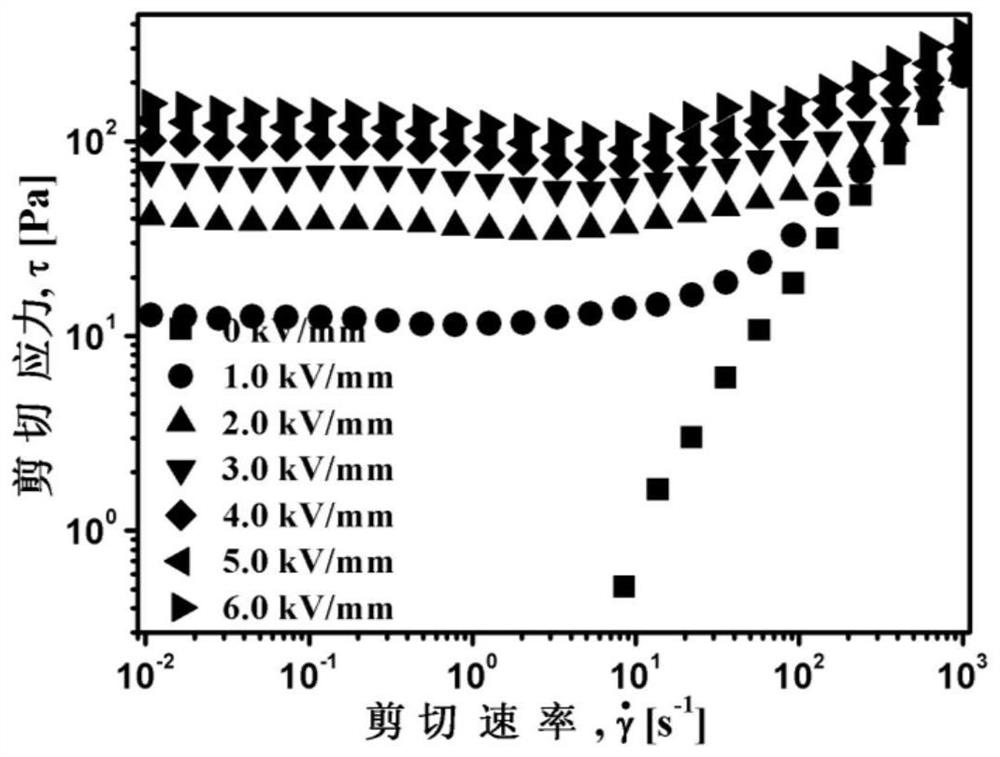

A nano-composite, electrorheological technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of slow response time, poor particle suspension stability, high leakage current density, etc., and achieve short reaction time and excellent electrorheological properties. , the effect of high shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

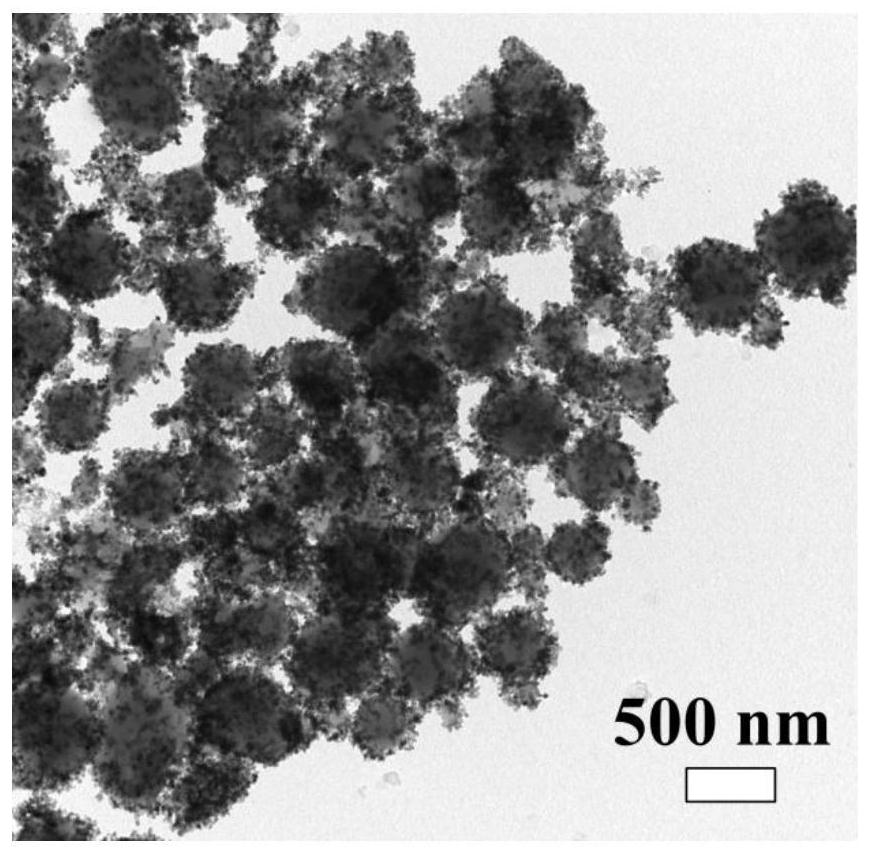

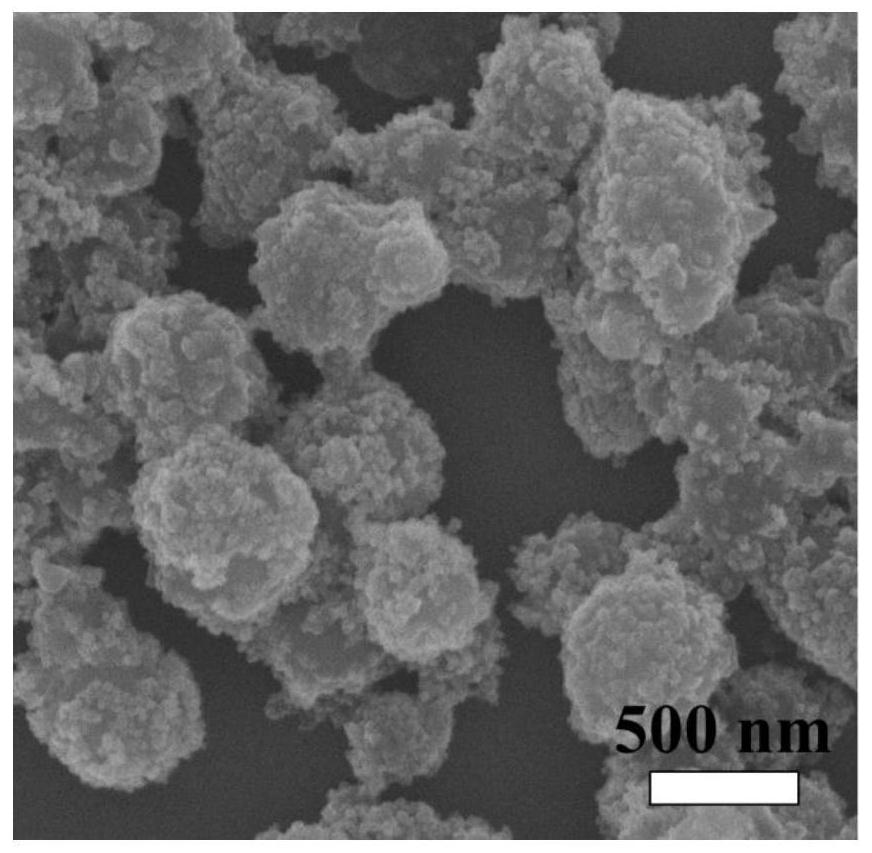

[0014] In this embodiment, the combination of oxidized Mxene and polystyrene spheres is selected, and the specific preparation process is:

[0015] (1) Preparation of etching Mxene: first weigh 5g of raw material Ti with an electronic balance 3 AlC 2 , and then use a plastic measuring cylinder to measure 75ml of hydrofluoric acid and place it in a plastic bottle, and put the raw material Ti 3 AlC 2 Slowly added to hydrofluoric acid, stirred at 250rmp for 72h, washed with deionized water until neutral, and freeze-dried to obtain Mxene after etching;

[0016] (2) Preparation of oxidized Mxene: First weigh 0.7g of etched Mxene with an electronic balance and place it in a 100ml beaker, then use a measuring cylinder to measure 70ml of UP water and place it in the beaker, crush the cells for 30min, and then place 1.5ml of UP water into the beaker. Hydrogen oxide was added to the above solution, dispersed evenly, the above mixed solution was transferred to a 200ml reactor, and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com