Covered yarn machine connection head knotting device

A technology of knotting device and covering wire machine, which is applied in the field of spinning and machinery, and can solve problems such as easy broken wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

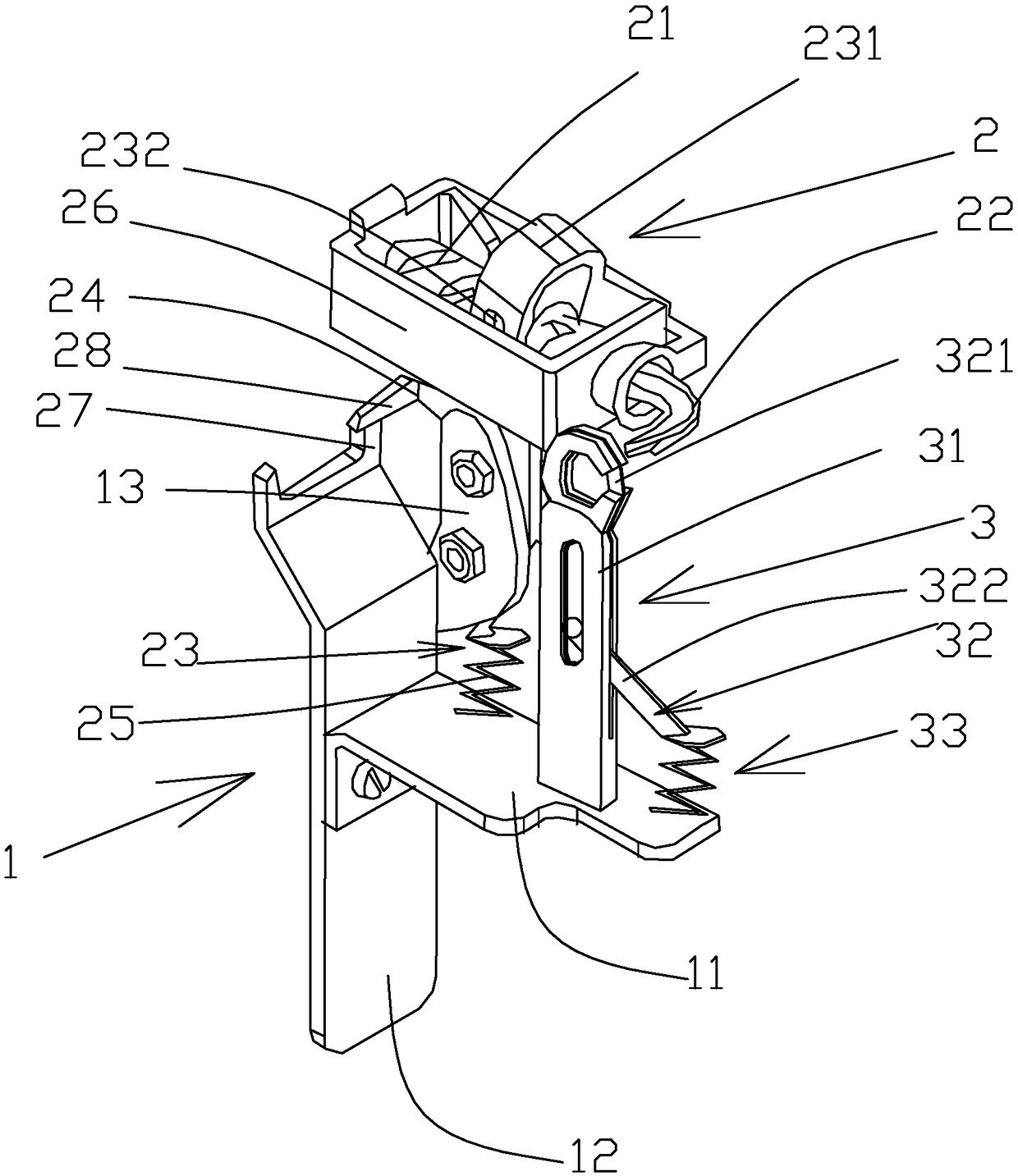

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0018] like figure 1 As shown, the joint knotting device of the covered wire machine includes a base 1 and a knotter 2, the knotter 2 is arranged on the base 1, and the knotter 2 includes a screw rod 21, a three-jaw knotting head 22, The control device 23 for controlling the rotation of the screw rod 21 and the knotted support 26 connected to the base 1, the return control device 23 includes a slide block 231, a control bracket 24 and a spring 25, and the slide block 231 is threaded with the screw rod 21 Connection, the control bracket 24 is rotatably connected with the base 1, and one end is connected with the slider 231, and the slider 231 is controlled to slide horizontally by rotating relative to the base 1. The side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com