Flexible packaging lithium-ion battery module and connecting method

A technology of lithium-ion batteries and ion batteries, which is applied to battery components, circuits, electrical components, etc., can solve problems such as high cost and connection reliability risks, avoid reliability risks, simplify manufacturing difficulty and cost, and be universal sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

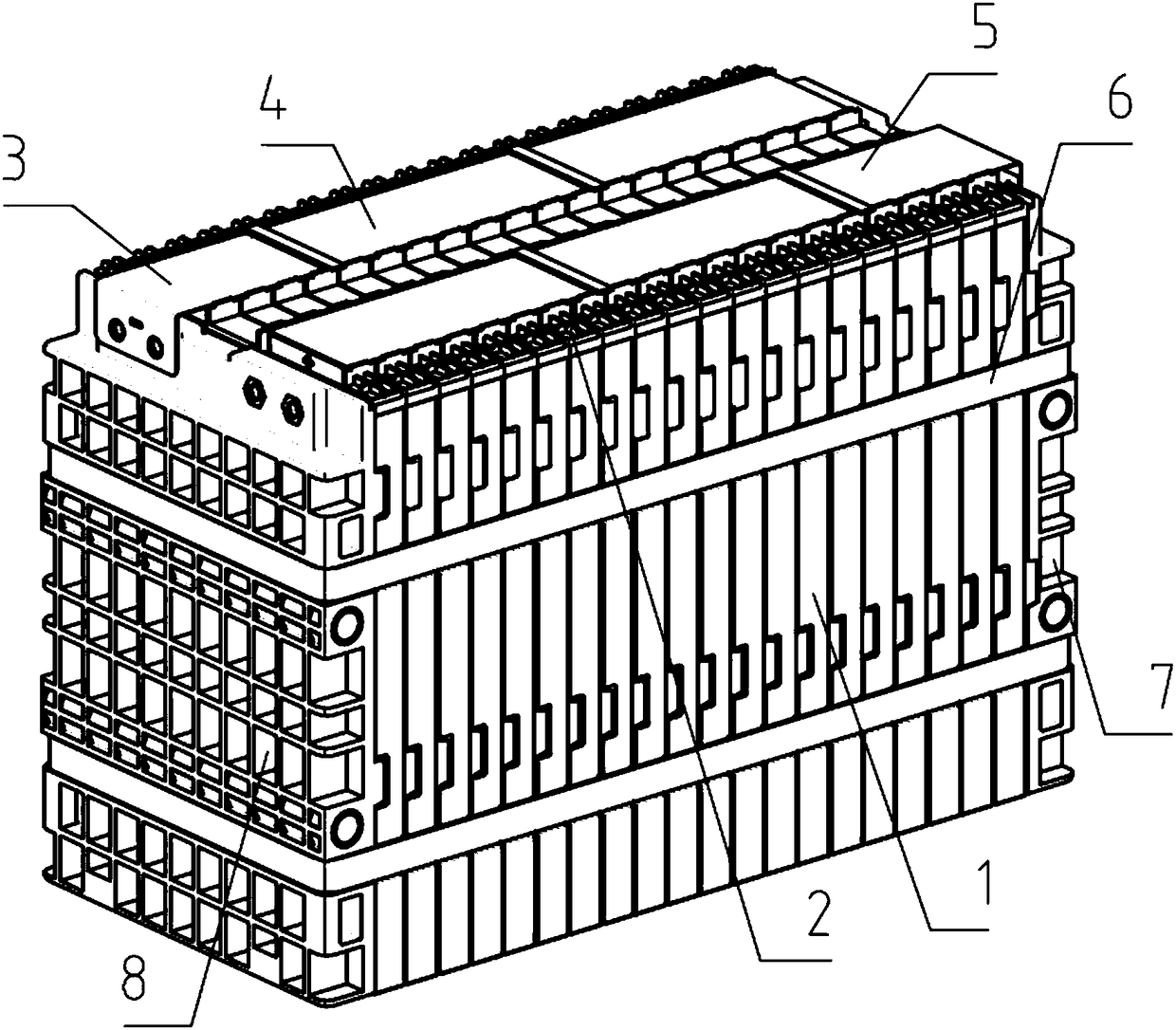

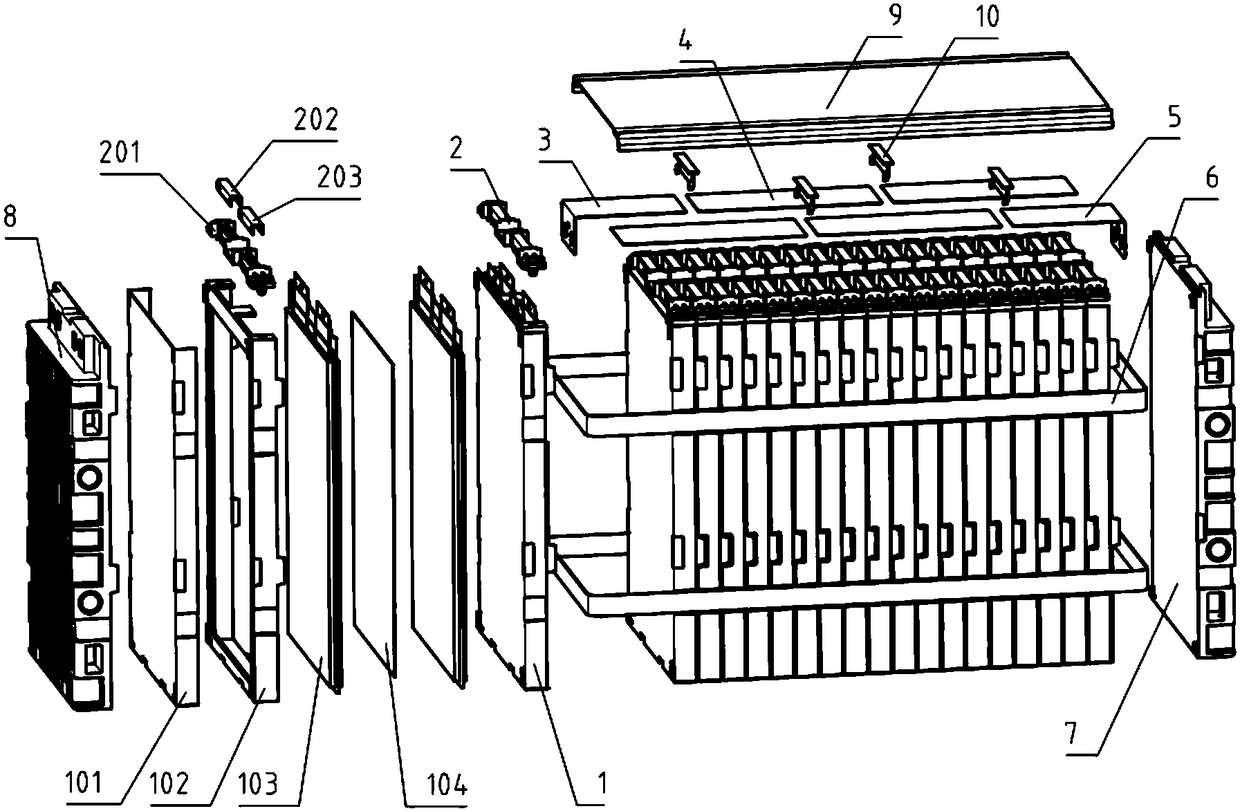

[0031] Such as figure 1 , figure 2 The shown soft-packed lithium-ion battery module includes a number of stacked battery cells 1, a front end plate 8 provided at the front end of the battery unit 1, a rear end plate 7 provided at the rear end of the battery unit 1, and a battery The unit 1 is bundled with the belt element 6 of the front end plate 8 and the rear end plate 7. A cover plate 9 is installed on the upper part of the battery unit 1 to cover the electrical connection structure of the entire battery module so that it is not exposed to the outside.

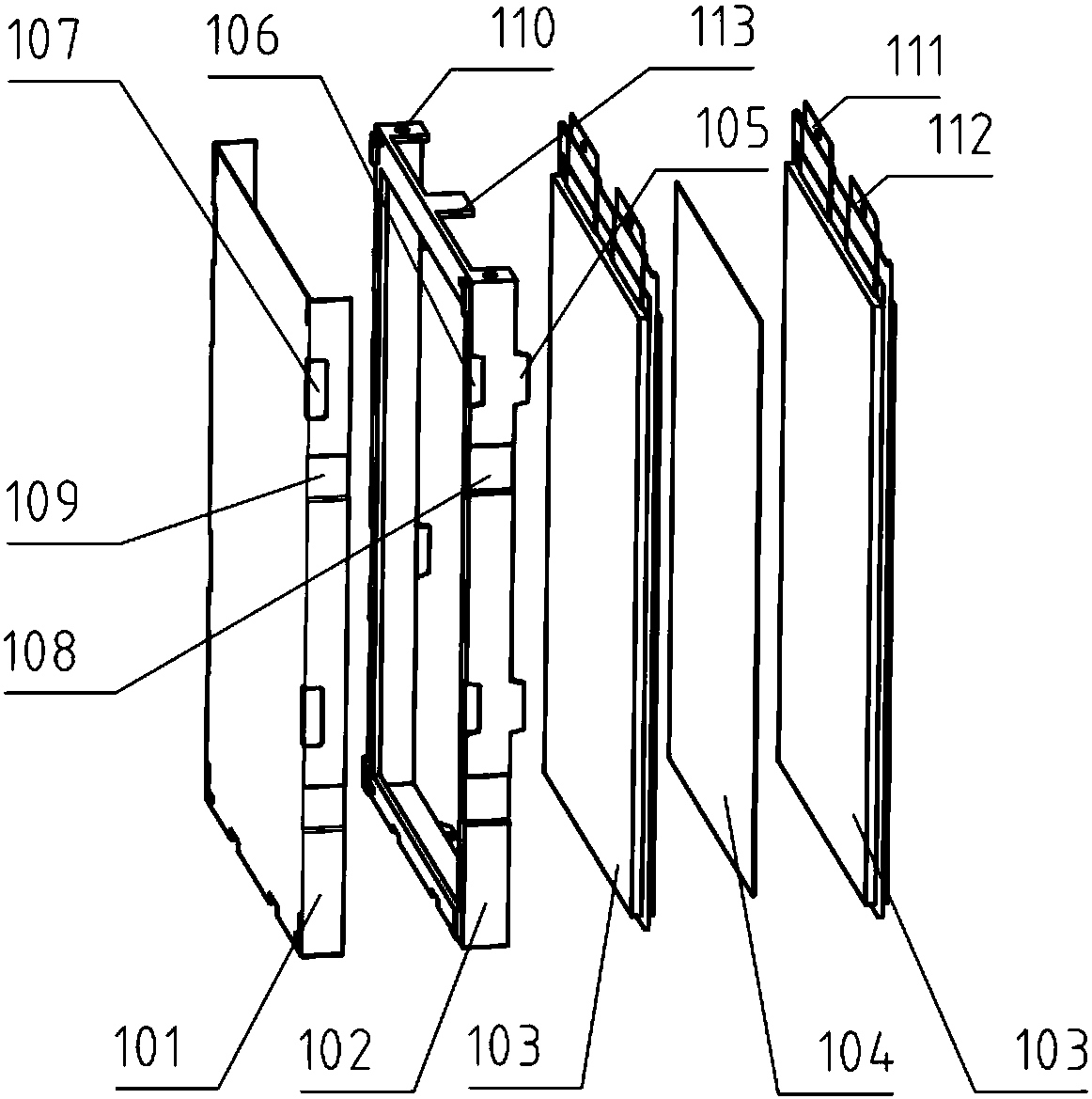

[0032] The battery unit 1 includes a fixed frame 102 and a bus bar located above the fixed frame 102, which are att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com