Copper-clad aluminum wire drawing device

A copper-clad aluminum wire and drawing device technology, which is applied in the direction of line/collector parts, electrical components, circuits, etc., can solve problems such as easy slipping, no storage box for maintenance tools, easy damage to copper-clad aluminum wire, etc., to achieve The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

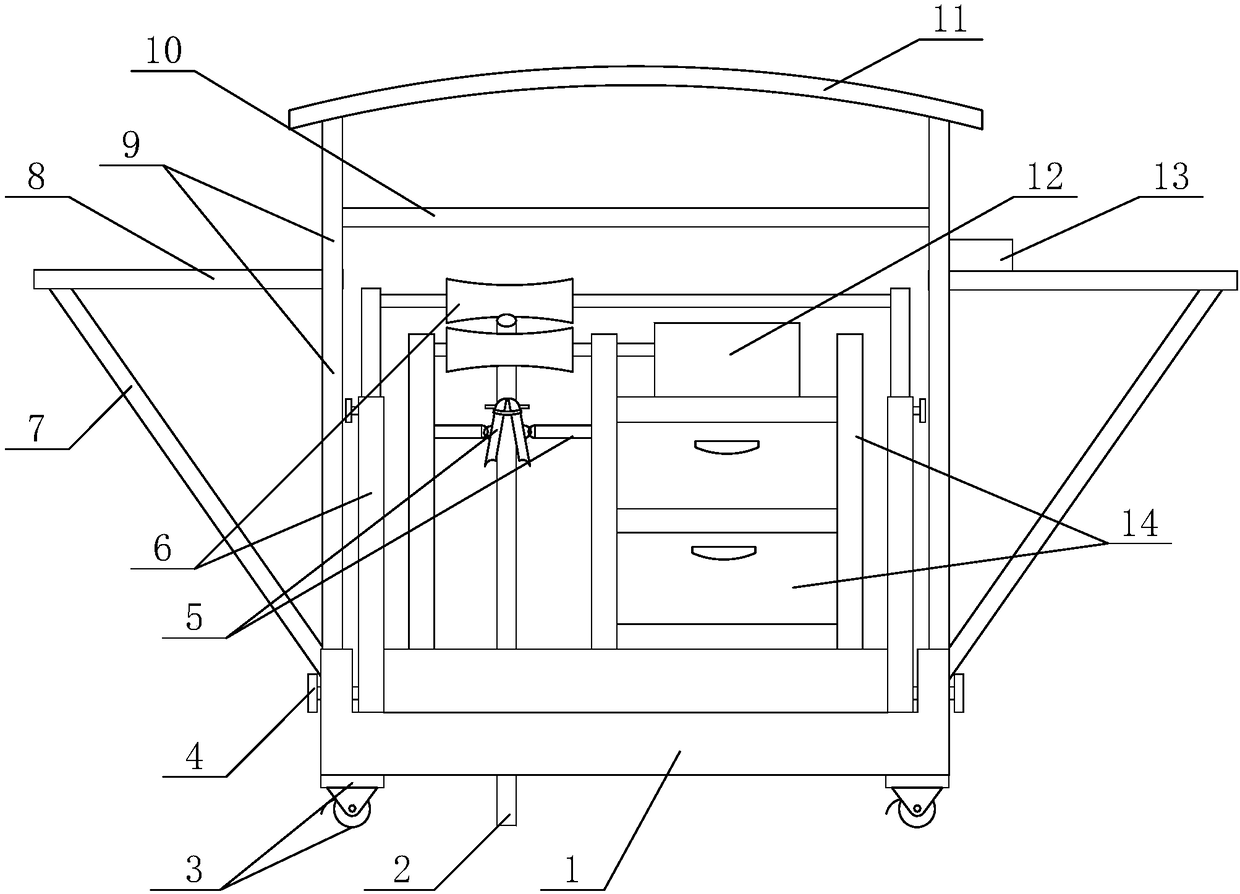

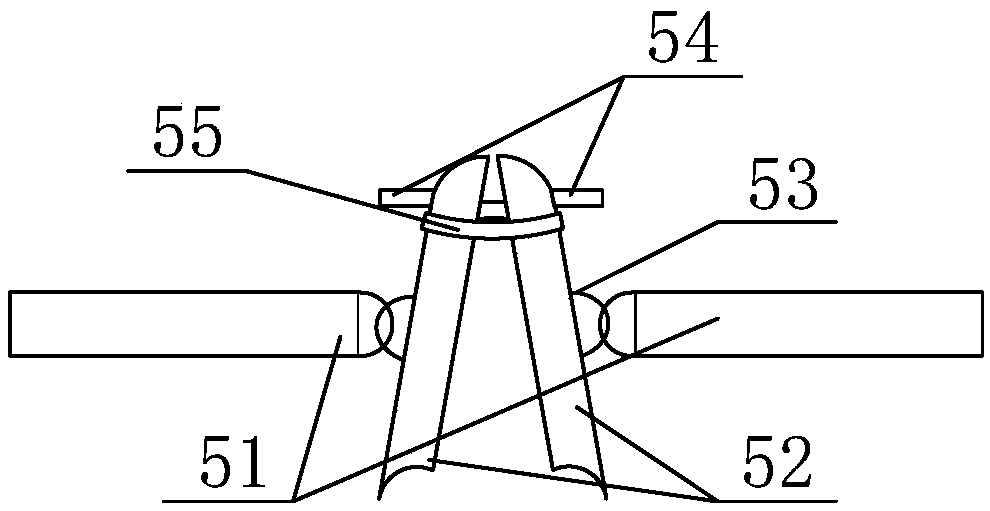

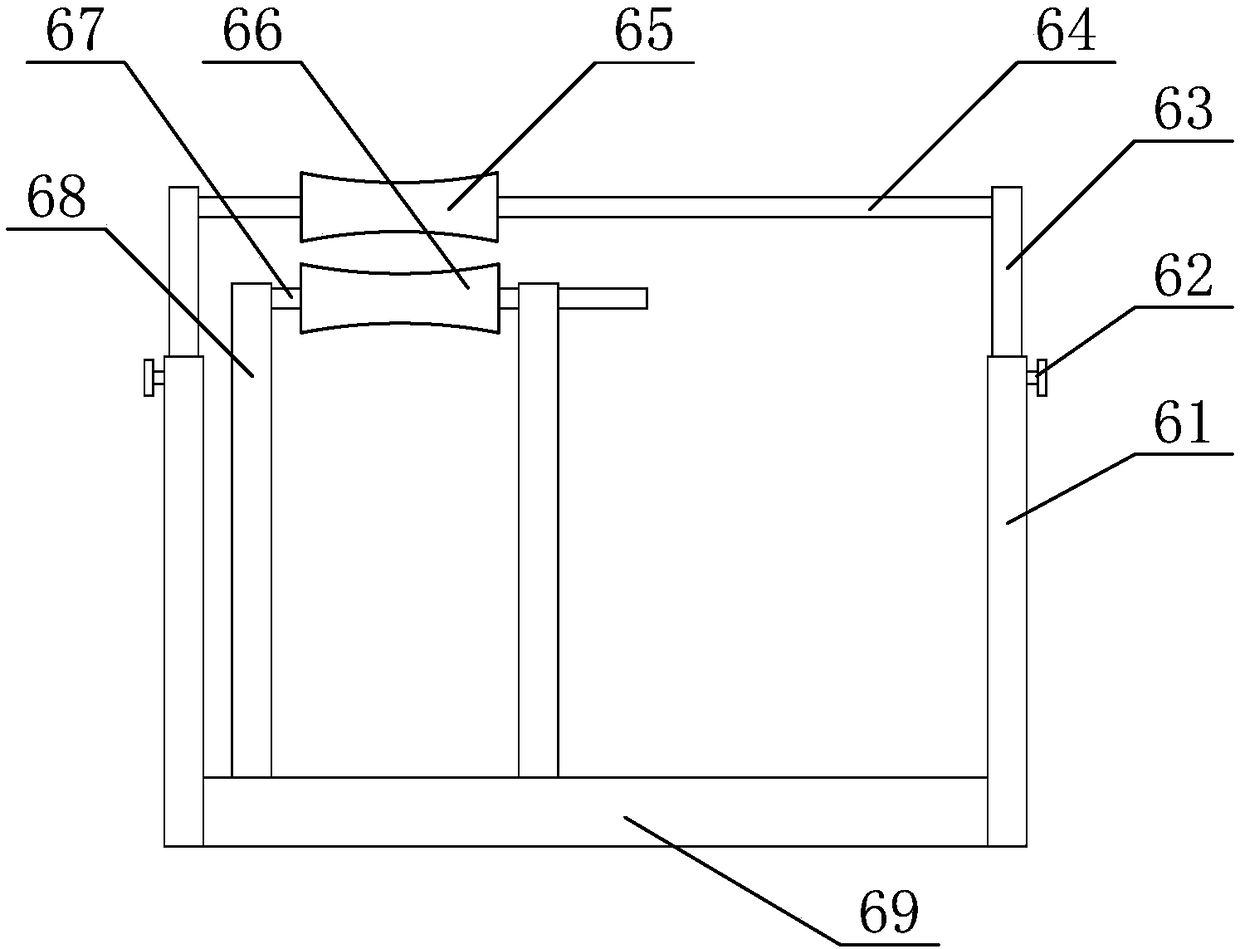

[0034] like Figure 1 to Figure 4 As shown, a copper-clad aluminum wire drawing device according to the present invention includes a base 1, a copper-clad aluminum wire 2, a moving wheel 3, a fastening hand wheel 4, an anti-slip device 5, and a pulling roller device 6, Reinforcing bar 7, hand bar 8, load-bearing bar 9, connecting plate 10, protective cover 11, power motor 12, control switch 13 and tool box device 14, and one end of the copper-clad aluminum wire 2 is longitudinally clamped on the drawing drum The left upper part of the device 6, and the other end respectively penetrate the left lower part of the drawing roller device 6 and the left inner position of the base 1; the moving wheels 3 are respectively bolted to the four corners of the lower surface of the base 1; The fastening hand wheel 4 described above is screwed to the upper parts of the left and right ends of the base 1; At the upper left end position of the tool box device 14; the drawing roller device 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com